In interesting in learning the basics on 3D printing tolerances? When you are 3D printing an object, no matter what the project, it is essential to know the tolerances available and what works for your specific need.

Engineers use tolerances all the time when designed and creating different 3D parts in their projects.

You want to test and determine which is right for you to show the dimensional accuracy and know your clearances for future printing.

Importance of 3D Printing Tolerances

For many 3D printing jobs, these are pieces that need to fit together like a puzzle, so the details are where they need to be. They do not have to be snug fits, allowing enough room for dimensional clearances, but they also do not need to be extremely loose, either.

Printer Calibration

If you are using a new printer or have not spent much time in 3D printing, you need to calibrate your printer to have an idea about the dimensional clearances.

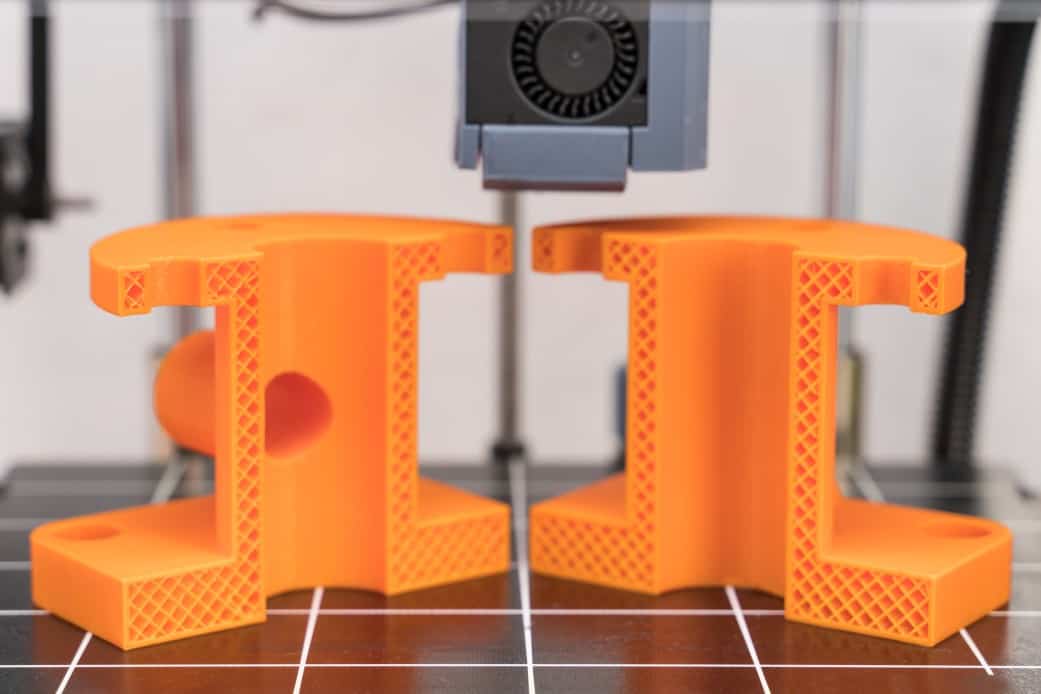

During an accuracy test, you need to print several versions and take measurements on all the versions. Once measured, you need to subtract the smallest size from the largest, giving you a dimensional clearance to move forward with when you continue printing.

Different Tolerance Fits

Know the difference in your tolerance fits so that you can print to accuracy as you need.

- Loose Fit Tolerance

- Tight Fit Tolerance

- Press Fit Tolerance

- Normal Fit Tolerance

After you have printed versions to test, you need to test the accuracy of the different tolerances on your printer to make the appropriate fits when the time comes for other parts. These different tolerances are ideal when you start to fit different 3D printed parts together and need them to work appropriately.

Loose Fit Tolerance

If a 3D part is meant to be used in the actual object, it is replicating. It could be a loose fit. This is all dependent upon the job of the part and how it is used mechanically. When you need to print 3D designs with an open fit tolerance, they are often more accessible, mainly because they have higher clearance.

These fits are usually found with food packaging and items that are not impacting a mechanical function.

Tight Fit Tolerance

These designs, when printed, are looked at more closely because their level of tolerance is much lower. They need to be more accurate and fit the dimensions closely before being used for their job. This tight fit tolerance is often the most used when creating multiple 3D parts for a design.

Much more accurate than the standard fit, this tolerance only allows for a hair of difference, give or take, when it comes to the printing dimensions.

Press Fit Tolerance

This is the most accurate and allows no tolerance in terms of dimensions. Press-fit tolerance means that it has to be exact, line to line with the actual part to replace and function appropriately. The printed replica must match the dimensions of the original precisely before it can be moved forward and used in the design.

These press-fit tolerances are often meant for pieces that will function mechanically and be used to perform an action job in a line of other parts that depend on those exact dimensions to be available.

Normal Fit Tolerance

In most cases, a bit of tolerance is allowed for the dimensions, which are above or below 5mm. This is considered a standard fit tolerance and will allow the newly printed part to continue performing the duties it was published for initially.

As you calibrate your printer, you want to keep it within this fit tolerance for all print jobs for the most accuracy. If you cannot meet the standard-fit tolerance, then it may be time to recalibrate your printer.

Improving Your Tolerances

If you need to improve your tolerance fits because you cannot meet the tight or press-fit tolerance, you have several options to consider.

Quality Filament

While you are trying to cut corners with cost, you can cut your quality by substituting cheap filament in your printer. The cheaper the filament, the looser the tolerance, making it difficult and nearly impossible for those tighter fits.

Learn more about how much filament to use.

Calibrate Regularly

For your printer to maintain the tolerance that fits your need, calibration should be a part of your routine. The more you print, the more calibration you will need, so make sure you are doing that regularly to ensure correct tolerances and accuracy. Depending on how frequently you use the printer, you may need a weekly calibration or something even more frequent.

Watch For Holes When Printing 3D

In almost every tolerance fit, the printed holes will often be undersized, so prepare for that dimension to be off. With different drills available, you can constantly adjust and drill the hole to match the correct dimension. If it prints too large, it cannot be fixed.