The Bowden extruder and Direct Drive styles are the two most common configurations of 3D printers when it comes to the 3D printers that are configured in the extrusion style. In terms of their hardware, you can find that these two configurations may be quite different. However, you can also find Bowden style and Direct Drive style 3D printers with extremely similar hardware.

The only difference, in that case, is that the Bowden style configuration comes with a longer PTFE tube. For this reason, comparing these two 3D printer configurations is not exactly straightforward.

One way to summarize this comparison is that Bowden configurations can print a little bit faster but Direct Drive style 3D printers give you more consistent results and can use a variety of materials, too.

Read on to learn more about the differences of a direct drive vs Bowden extruder.

Important Terms to Know

When looking at these configurations, the most important terms to understand are PTFE tubing, extruder as well as extruder assembly, and hot end, in addition to hot end assembly.

Extruder assembly is made up of an idler that is mounted to the 3D printer’s frame or gantry, a drive gear or hobbed bolt, and finally a stepper motor. However, the extruder itself includes the idler, gear, and motor.

The assembly includes all the other parts of the extruder. The hot end assembly mostly consists of a heatsink, heat block, and nozzle. All of these are mounted onto a 3D printer’s gantry. A cartridge heater, specifically one that is a resistive type, heats up the nozzle assembly as well as the heat block.

Since there is a hot end, there is also a cold end of the printer, as you might expect. The rest of the hot end assembly as well as the heatsink are called the cold end.

This does not mean that that part of the 3D printer is actually cold. It really just means that the heatsink separates the 3D printer’s heat block from the rest of the printer’s parts. Additionally, the ‘cold end’ also cools the assembly down by radiating heat away from it. It is easy to just use the term ‘hot end’ for the hot end assembly.

The extruder, such as the Bowden extruder, consists of the idler, gear, and motor. The extruder assembly includes the rest of the parts that make up the extruder system.

What Is PTFE Tubing?

It makes sense to start off with the acronym PTFE. PTFE is an acronym for Polytetrafluoroethylene. There are many variations of Polytetrafluoroethylene. However, the PTFE variation that is the most well-known is Teflon.

You can connect this tubing to either a direct drive or a Bowden extruder system. Typically, either fittings or push-fit connectors connect it to the assembly. This helps make sure that there is a seamless transition from the extruder itself to the hot end of the assembly.

Extrusion Configurations 101

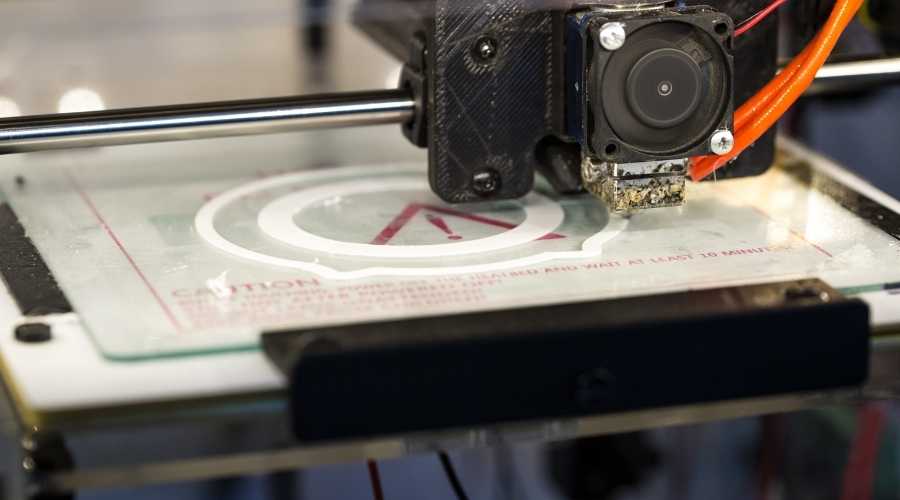

A 3D printer contains many important parts, but you can argue that the most important part of it is its extrusion system. Fused deposition modeling is a popular type of 3D printing technology. The two main reasons for its popularity are that it is quite affordable and easy to use, as well.

You certainly don’t have to be a 3D printing expert to use an FDM 3D printer. The extrusion process starts at the extruder assembly on FDM printers. The 3D printer grabs the filament between the idler and the hobbed bolt and pulls it into its system.

When it comes to comparing direct drive systems to Bowden systems, the difference is that the filament goes through a nearby hot end in a direct drive, but in Bowden systems, a PTFE tube directs the filament to a hot end. You should also know that the PTFE tube in the Bowden system is two to three feet long.

Direct Drive Style and Bowden Style Are Very Common Configurations

Extrusion-style configurations are one type of configuration used in 3D printers. As you might have guessed, the Direct Drive style and Bowden style are the two most common types of configurations made in this style.

You should recall that these two configurations can be quite different in terms of hardware or they can be extremely similar in terms of hardware. This is one reason that comparing the two configurations is not exactly straightforward.

Bowden configuration 3D printers can work well for printing products for a business since you can print them out more quickly.

In contrast, Direct Drive configuration 3D printers print flexible materials like TPU quite well. This means that both beginners and experienced people can print out TPU, which is both durable and flexible.

What Are Some Strengths of the Bowden Configuration?

Each configuration has different strengths. For the Bowden configuration, its primary strength is the fact that it is capable of printing more quickly than its Direct Drive style counterpart. There is a bit of separation between the hot end assembly and the extruder assembly in a Bowden configuration 3D printer.

As a result, the Bowden system offloads the extruder’s mass onto your 3D printer’s fixed frame. This is something you should keep in mind since constant deceleration and constant acceleration can lead to gantry backlash.

These negative effects only get worse when you put more mass into the 3D printer. All of this movement makes the hot end lurch backward and forward.

Since the hot end lurches back and forth, the printed part often ends up with imperfections. If the 3D printer moves with a smaller amount of mass on its gantry, it means there is a smaller chance of these vibrations happening.

What Are Some Drawbacks to the Bowden Configuration?

The main drawback of the Bowden configuration is that this type of 3D printer can only print some kinds of materials at adequate resolutions. When it comes to 3D printers with Bowden configurations, including a Bowden extruder, they tend to print more rigid materials better than materials that are a bit more flexible.

ABS and PLA are two types of materials that usually do well with particular Bowden configurations. You can learn more about ABS here.

ABS is the acronym for acrylonitrile butadiene styrene. It is a type of plastic and the 3D printer guides it into an extruder that then heats up the ABS plastic enough that it melts and liquifies. In any case, Bowden configuration 3D printers have to meet certain conditions to print flexible materials well. These conditions are:

- Large retraction settings to prevent oozing from occurring

- Tight tolerances in the PTFE tube which connects the hot end to the extruder

- Hobbed bolt with a deeper profile to grip the flexible material better

What Are Some Strengths of the Direct Drive Configuration?

One major advantage of direct configurations is that they are quite responsive. This is because there is less distance between the hot end and the extruder. As a result, both retraction and extrusion commands go through more quickly.

The direct configuration 3D printers have material deposition control that is more reliable. You can print using flexible materials more easily with direct configuration 3D printers and will often get better results when doing so, too.

What Are Some Drawbacks of the Direct Drive Configuration?

Direct Drive configurations print more slowly than Bowden configuration 3D printers. You should know that the other hardware in the printer can limit printing speeds.

Even if the extruder of the Direct Drive moves at a certain speed, the hot end may only be able to heat then discharge a specific amount of material at that time. In that instance, the hot end is what limits the 3D printer’s printing speed, not the configuration.

Which Configuration Should You Choose?

The three most critical factors to take into account when you choose an extrusion system are the resolution, the correlation between resolution and time, and also the diversity of materials.

If you value printing speed above all else, the Bowden configuration might be best for you. If you value the 3D printer’s ability to print flexible materials, the Direct Drive configuration could be a better choice for you. It depends on your specific needs.