In the world of 3D printing, many have made a choice on which filament they prefer, and the division falls between either the PETG Filament vs PLA.

PETG filament or in its formal name, polyethylene terephthalate glycol is a flexible and pretty easy co-polyester that is found in a lot of 3D printing projects.

PLA is also a polyester filament, or polylactic acid, which is a more eco-friendly version. There are more differences than these, however, and a characteristic comparison will be broken down between the two filament options.

What is PETG?

PETG is one of the most common plastics and co-polyester materials used in the 3D printing world. Chances are that your everyday items that you have used today or will purchase later have been made by PETG filament.

This includes items like water bottles that are used more frequently and even plastic dishes that are used for food. PETG is pretty common among household and even commercial items because it is safe and durable within a number of industries.

What is PLA?

Since PLA is a polylactic acid, it is often made from the raw materials of cornstarch or other vegetable bases. Its most common use is found in manufacturing with additives because of its full biodegradability.

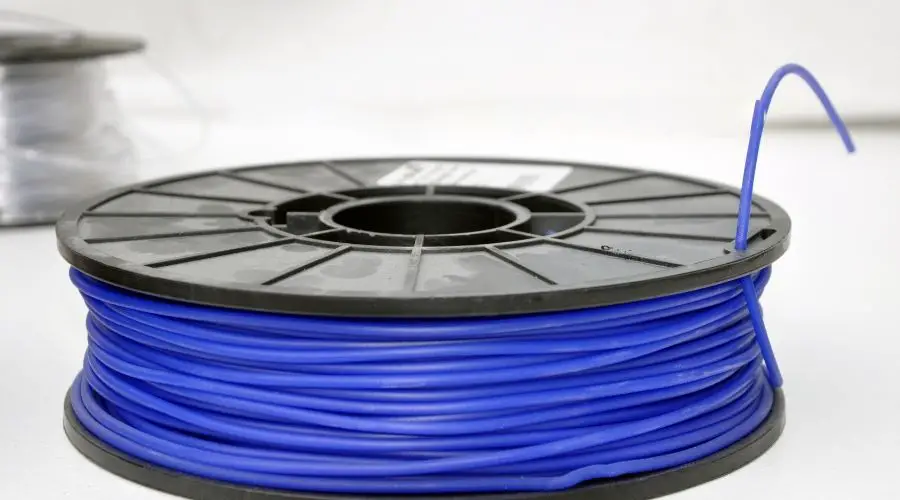

This material opens a spool of wire so that it can easily be fed into the extruder head of the printer. From here, the plastic is melted down so that it can then be deposited in the printing tray continuously throughout the project, while it is required. In order to get this PLA filament colored, you will need to have the spools already colored so that the object is made in that particular color.

Because of its material properties, PLA is able to be used for large projects that require mass printing and prototypes to be produced in a smaller window of time. Because of its versatility, PLA is also used to develop tool parts in the manufacturing industry and end-use parts that may need to be replaced often due to excessive use.

Related: Comparing PLA vs ABS

Comparing PETG Filament vs PLA

Before you make a decision on which filament you need, it is essential to know the difference between PETG and PLA options. They do vary in strength, durability, and even safety because of the materials used for the process, which makes them ideal for different types of developments.

Strength

Depending on how you determine the strength or even what project you are working on, you may find one filament to be the better option over the other. The long-lasting debate between PLA or PETG filament is which is stronger. When it comes to the breakdown of the tensile strength, then PETG will stand out compared to PLA each time. The objects that are printed with the Petg are much tougher than other options and can withstand different environments because of this durability.

For example, PETG is used to make hard plastic dishes that are able to withstand the heat from a microwave and also the heat from a dishwasher. This type of durability means that a variety of project options can be printed in mass and are more affordable because of their strength.

When it comes to PLA, it does have some strength to consider. It certainly will hold up in a few significant environments after it has been printed. For example, the PLA can be used to make hooks and mounts that can hold pictures and shelving without bending or breaking. Of course, these environments where they are used are often climate-controlled, because PLA and heat are not as friendly as heat and PETG . If the function of the part being made by PLA is to be stationary and just maintain weight, then it can be considered a strong product and a contender for your particular project.

Heat-Resistance

As mentioned earlier, PETG is able to withstand much warmer environments than its PLA counterpart. For example, being used in a microwave or even washed in a dishwasher with excessive heat and water for several minutes can be enough to break down PLA into biodegradable pieces.

The heat resistance on the PLA is very low, so it should not often be considered for functional objects. If it is going to be used in a functional atmosphere, the heat must be low, and it must not have direct sunlight. The heat from UV rays from the sun will start to break down the PLA print and begin the biodegradable process.

It is also important to note that PETG is waterproof, which is much different than other filament options. This makes it ideal for outdoor prints that will be exposed to a variety of weather patterns on a regular basis. Outdoor parts or items that will be carried around when it is warm or in the rain need to have this filament, otherwise, the PLA will start its breakdown process right away.

Safety

When it comes to safety in filaments, many printers make a decision based on this feature alone. Where PETG is stronger in features, PLA is actually safer. This is simply behind the fact that it is organic, does not have any added harsh chemicals, and cannot bring any type of chemical harm to the person who is around or using the PLA on a regular basis. Because of its organic and biodegradable make-up, it has a natural smell that is pleasant or unnoticeable to those around it. This is good for those who have allergies or sensitivities to products on a regular basis.

PETG , however, is considered safe but does not have the same desirable features as PLA. While it is still supreme above other lower grade filament options, the PETG does come off and having an odor after the object is printed and being used regularly. This is only on prints that are used in high temperatures, though, where there is direct sunlight or an increased temperature. If the climate is cooler, then the odor seems less and is still nowhere near as strong as ABS filament after it has been printed. It is not as natural as PLA, therefore it cannot maintain the same types of safety and organic claims that PLA carries on a regular basis.

Convenience and Ease

The test of ease is probably the most important feature of these two filaments. Whether you are just entering 3D printing or starting a new project, you want to use a filament that is easy to use and convenient during the process. Not all filaments are easy, but the PETG and PLA seem to be some of the best options available in terms of filaments and what is offered.

If you are a beginner at 3D printing and just learning how to use the different components, you may find that PLA is the easiest to use. Because this filament just spools directly into the extruder head, making printing easy, especially for large projects. They make the quality and the success of the printing much easier for beginners.

The PETG filament is not much harder to use than the PLA, but it does require some experience and knowledge of the 3D printer by the person managing the project. What this means is that before you start printing with the PETG filament, you need to make sure that the right settings are locked in on the printer in order for the print to be successful. If you are familiar with 3D printing and know how to calibrate and use a 3D printer, then using the PETG filament will be just as easy as the PLA.

Color Options

Whether you are using the PETG filament vs PLA, you have color options for each one. If you are using the PLA, you need to make sure the spool is colored beforehand, and these projects are almost always printing in a single color. Depending on how much detail you want to be reflected on, you can choose either bright or dark color options.

Final Product Shrinkage

All 3D prints do go through a level of shrinkage when they are cooling off after the print. This is common for all filaments, and all 3D printer operators should know what this shrinkage difference is in each filament. The good thing about these two options is that no matter which filament you choose, the shrinkage is much less compared to other filament options like ABS or Nylon.

In PLA, the shrinkage amount during the cooling system is minor, with just a slight percentage difference. This is a tolerance that can easily be accounted for during the printing process so that your object is printed to the appropriate measurements. If you are looking for a successful print and one that will stay very close to the same printing size, then PLA is the best option.

For PETG , it does have a little more shrinkage than PLA, but it is also a small amount that can easily be accounted for in printing tolerances. Compared to ABS, PETG does have much less shrinkage concerns and is less than 1% overall.

Which Filament is More Affordable?

If you are considering cost as a factor between PETG filament vs PLA, then there is some small variation between the two. PLA is found to be more affordable than PETG , at around a 20% cost decrease compared to quality PETG options. PLA is very affordable, especially if it is not colored. If you do opt for PLA color, then you may have to pay a few additional dollars. For a small project, this cost amount may not be significant enough to make a difference. However, if you are planning to print various prototypes and make a mass print, then this can be significant in the overall bundle cost.

Final Print Looks

While the look of PLA after it has been printed has a more tough and natural look, the final print on a PETG filament often comes off glossy and translucent. More details are often defined in the Petg print, which may be critical, depending on the type of project you are printing and the goals you have.

Since there is more shrinkage to consider for a PETG print, it is a good idea to make sure that your cooling fan is off on the first layers of your print. PETG filament has been known to have a warped look caused by the cooling fan early on, affecting the success rate and overall look of the print. You can apply this same method to PLA prints if you have the time, but since the shrinkage is so low, the chances of warping are much smaller than with the PETG .

Choosing The Right Filament

A concluding review of these two different options determines that both options are great depending on the type of project you have and how you plan to use the print once it is finished. For some projects, the PETG filament is stronger and the better option. Make sure that you take into consideration these different factors and which are the most important for you and the project at hand. If you are planning to have your final print outside in the environment or using it in a climate-controlled space, then you need to choose based upon the answer to that question. No matter which you choose, it is important to know that both of these filament options are some of the best filament options and can still produce a successful print.