There are many things that creators who use 3D printers have to keep in mind. One of these things is that you need to understand how crucial it is to select the appropriate infill pattern in addition to choosing the correct percentage.

This is critical, no matter if you are making working parts for actual production or if you are just making parts for prototypes.

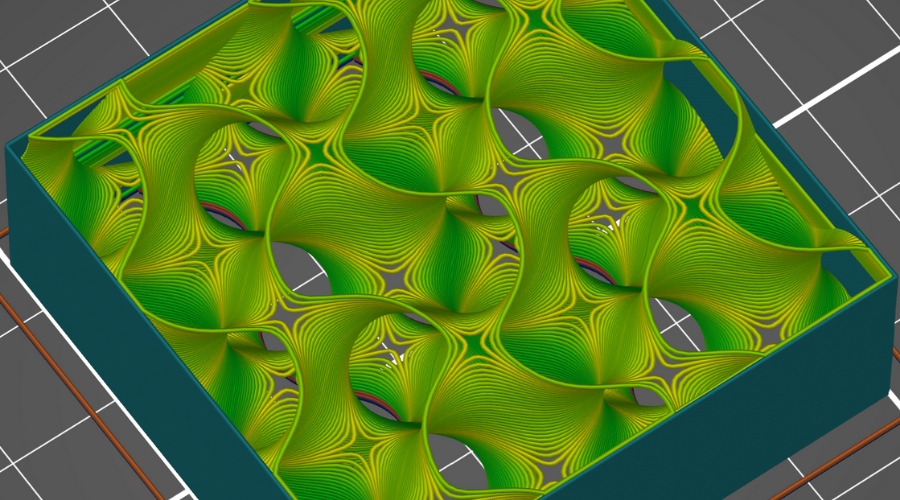

As far as the Gyroid infill goes, it is one pattern that you can choose for your 3D printing. It is best known for its cubic symmetry. This particular pattern differs from other 3D printing patterns because it is capable of resisting forces coming from every single direction equally.

The general strength and overall resistance of the Gyroid infill is its primary strength. You will find that this remains true, even when the infill percentages are lower.

Basic Info about A Gyroid Infill

As a starting point, it is relevant to mention the fact that the majority of objects created by 3D printing require connections between the top or bottom layers and the perimeters in their internal structure. For this reason, when slicing, you establish both a percentage as well as a pattern for the infill. Every kind of structure comes with strengths and weaknesses.

The creators of objects via 3D printing tested unique designs and eventually new methods of filling parts created by 3D printing were invented. Studies done a few years ago in 2017 focused on graphene structures that were some kind of Gyroid. These studies found that the Gyroid shape provided the 3D printed parts with incredible resistance.

The extruder is the part of the 3D printer that creates the Gyroid infill and constant bending movements of the extruder make this infill. You get stable movement in addition to filament deposition that is continuous.

The Gyroid infill includes a similar amount of resistance as honeycomb infills. You can see the infill repeating its own shape in every single layer. As is obvious, these infills are based on the honeycombs that you can find in nature.

You do have to distribute the resistance of the object equally for each axis. As a result, you actually end up having an infill percentage which is an improvement in terms of efficiency over other types of infills. This Gyroid-style infill is nearly isotropic. However, instead of being a hindrance, the fact that it is nearly isotropic is really a major advantage.

Gyroids 101

One technical term for a gyroid is a triply periodic minimal surface. Each of these surfaces does not interact with any of the others. For this discussion, the most relevant information is that a 3D printer can replicate them.

The cubic symmetry of the gyroid is its most critical characteristic from a 3D printing standpoint. As you know, many different patterns for infills exist. The gyroid pattern is the best pattern if you are creating a part that you are certain necessitates pure strength. A piece with this particular sort of infill is capable of handling larger loads with less material.

What Are The Gyroid Infill’s Properties?

Quite a few people have tested out this type of infill. Typically, the reason that they do this is to figure out if its properties are actually superior to those of the honeycomb infill pattern or not. As you may know, the honeycomb infill pattern primarily draws inspiration from hexagons.

Through these experiments and tests, we have discovered that the gyroid infill pattern utilizes less material compared to other infill patterns. Additionally, this pattern is both quicker and stronger than these other patterns, too. If you don’t account for perimeters, the weight of the gyroid is nearly 30% lighter than that of the honeycomb pattern. Choosing the gyroid pattern can save you both time and money and without any serious issues, as well.

What Are The Advantages of Gyroid Infills?

No matter what kind of infill pattern you use, there are always pros and cons. One advantage of using this kind of infill is that it is nearly isotropic. If the material is isotropic, that means that it maintains all of its properties in any possible direction.

By the mathematical definition, the Gyroid Infill is not isotropic. However, it is symmetrical in all three of its axes. Thankfully, the gyroid offers excellent resistance to any direction of forces as well as any combination of forces, too.

Its overall strength is another advantage of this infill. You don’t even need to use perimeters in order to print the Gyroid infill. By contrast, some other objects only contain perimeters in crucial parts. The object’s other infill patterns must lean on its perimeters. If these patterns did not do so, it would lead to a collapse of these patterns’ structures.

They Print More Quickly

The gyroid prints between two and five percent more quickly compared to a rectangular pattern if the infill percentage remains the same. The differences in printing speed become even more significant when viewing them from a mass production standpoint. Using this infill pattern can help make mass production of objects a smoother process.

They Require Less Material

One more advantage of using a gyroid infill is that you can make a piece that is still quite resistant with a smaller amount of filament. You can even print it without any walls and not affect its ability to function at all. Because of this, you could choose to go without walls and decrease the weight of the piece even further.

They Contain No Weak Points

There are no structural weak points due to the fact that the lines remain continuous and the infill’s entire layer is continuous, too. This also has the added benefit of limiting the chance of nozzles becoming clogged or of any issues with the extrusion.

They Maintain the Exact Same Resistance In Any Direction

You might find that you must print an object with a certain orientation. However, this orientation is not necessarily the same as the one needed to make sure the object has optimal resistance. You don’t have to worry about this if you use a gyroid infill, because its resistance is the same in any direction.

You Might Be Able to Use Less Sturdy Materials

Nylon and ABS are two obvious choices if you require a strong object printed by a 3D printer. Both of these are resistant, in addition to being quite sturdy. A gyroid infill increases the PLA resistance of the object but it also makes it easier to print and more affordable.

Fluid Can Go Through It

Another advantage of this pattern is you can choose it for applications that need water flow or airflow. Heat sinks and electronic packaging are just a few examples of such applications.

What Are The Drawbacks of Gyroid Infills?

As with any pattern, there are drawbacks to this pattern. One drawback of gyroid infills is that it can take quite some time for the slicing to finish if you are utilizing a computer that isn’t high-performance.

Utilizing the gyroid means that the G-codes that are created are typically larger. As a result, prints may even fail if you have connected the printer to your computer via USB.

One more drawback of using the gyroid infill pattern is since the extruder moves quite a bit in all directions, this can lead to undesirable vibrations. The extruder transmits these vibrations to the object and this is even more true when the extruder is moving at high speed. Gyroid infills can be a good choice for you, depending on your specific 3D printing needs.