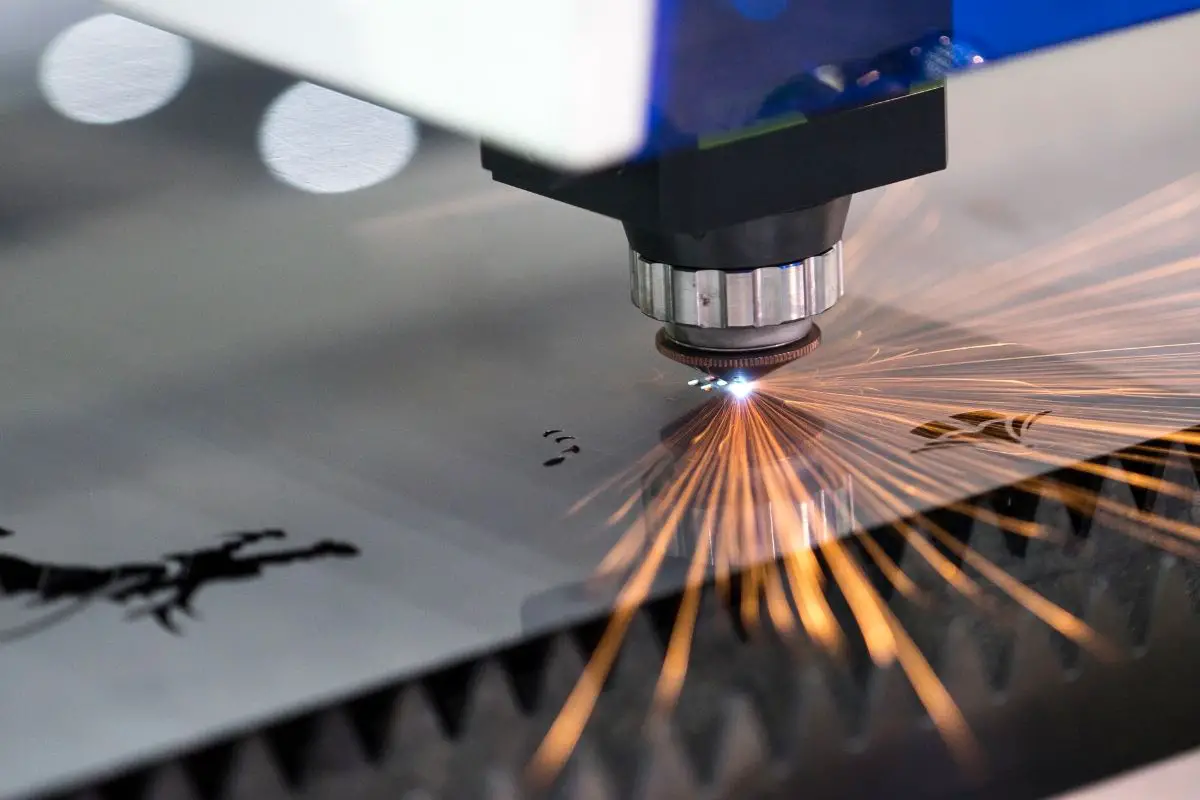

We’ve all probably seen a laser cutter in action. If you are like most people, the first time you witnessed it, you were most likely filled with curiosity. We’ve all asked ourselves the question, how does a laser cutter work and how was it invented? If that question is still itching your brain then you are in luck because we have all the answers.

How Does a Laser Cutter Work?

The laser beam is a column of high-intensity light of one wavelength or color. Most lasers today are CO2 lasers. What makes CO2 lasers interesting is that despite them being 3/4th of an inch, a part of the beam is invisible to the human eye.

To make it as simple as possible, some wavelengths are invisible to us because our eyes can’t detect these wavelengths. That is because these wavelengths are longer than those of visible light, making it impossible for us to see with a naked eye.

Back to the process. The beam will travel through something called a “laser resonator.”

This is what creates the beam. Once created, the beam of light will travel through the machine’s beam path then through a number of beam benders. It then goes through the nozzle and now you have a laser beam shooting out of the device.

Now that you know how a laser cutter works let’s dive into the history of laser cutting.

Laser Cutting History

The first time a laser was being used for cutting was all the way back in 1964. Believe it or not, it was a gas laser beam that was being used at the time. In 1965, the first production laser cutting machine was created. At the time, it was used to drill holes into diamond dies. As mentioned earlier, most lasers today are CO2 lasers.

This technology didn’t come around until 2008 despite being found in the early 1970s. The reason being it took almost four decades to be used in production.

This was due to the fact that the CO2 lasers back then didn’t have enough power to get past the thermal conductivity in most metals. Why waste time using a CO2 laser when a gas laser can cut through metals just fine? This made CO2 an unreliable option and people put it on the back burner for the time being.

Now back to present time and you can see CO2 lasers being used all over the place and in fields such as medical, electrical, and automotive.

Now, it would be wrong of me to not mention another reason why laser beams became so popular. I’m sure that you have seen at least one Star Wars movie in your lifetime or know the general premises about the franchise. All the lasers shooting out of ships and guns you see in those movies are what a lot of people think about when they are talking about laser beams.

While there have been great strides in this particular field, we are still quite a ways away from having intergalactic ships shooting laser beams at each other.

But still, there are advancements being constantly made and it’s very exciting to see what kind of laser technology we will have in 40 years.

Laser Cutting Today

There are so many important factors in our life that use laser cutting in some way, shape, or form. They are very precise and can make almost any geometrical shape with extreme accuracy. Here are some ways laser cutting is used today.

Medical

A lot of tubing is used in the medical field. Obviously, the tubes have to be as precise as possible. In the medical field, the smallest detail can be the difference between life and death. Being able to be used as a “non-contact” tool makes laser cutting even more valuable because when using tools that come into contact with the equipment, they can cause damage or cause bending.

Automotive

It should come as no surprise laser cutting is used in the automotive industry. Cars have a lot of parts inside them. Many are big and many are small. But if you want to get thousands of pounds worth of parts to work together and make a car move, these parts are going to have to be made with an extreme amount of precision.

Another factor as to why the laser cutting process is so widely used in the industry is because it’s safer. More conventional methods use blades when creating the parts. While this method can still be safe if done with extreme caution, it’s nice to not have to worry about this in the first place and instead use a laser.

Electrical

Do you remember back when computers first became a thing? Remember how huge and bulky they were? One of the reasons why you can now get a computer half the size of an older computer is thanks to laser cutting. Parts have become smaller but more powerful as each day passes by, allowing us to have more powerful devices at smaller sizes.

Think of how many devices you have today such as your phone, laptop, handheld gaming device, or even the device you are using to read this article. These things would not be possible today if it weren’t for laser cutting. This alone should show you how big of an impact laser cutting has had on our lives.

Engraving

Yeti Cups are one of the most common items being engraved today. People love to get neat little designs on them and this is all done with a laser. Another item that’s common to get engraved in jewelry. Many people like to wear rings with designs on them or with a name written on it. If you want your ring to have a cool design, you are going to have to get it engraved with a laser.

And there’s so much more. So many designs are used using lasers. Despite this technology only being around since the mid-’60s, it has continued to grow and be used in many different fields. How far technology can go will depend on how far laser cutting technology can go.