Interested in learning about the different types of laser cutters for makers? This guide’s for you.

If you’ve been curious about investing in laser cutting technology for your business or hobby, you’ll quickly realize there are several options and designs on the market.

And there are major differences in the cost, performance, and material compatibility when it comes to the main types of laser cutters: hobby diode laser engravers, CO2 laser cutters, and fiber laser cutters.

In this post, we’ll guide you through the differences, covering how each laser cutter works, materials, types of projects they’re best for, and recommended models from each category.

Let’s get started.

Hobby Level Diode Laser Cutters

Over the past few years, a new class of very affordable desktop laser cutters has flooded the market. These are the open-frame, diode laser cutters that you can find on Amazon and other online retailers.

Most of these machines are manufactured in China and offer an easy way to get started with a new laser-cutting hobby or even a side business.

They are more affordable than popular CO2 models like the Glowforge, easy to set up, assemble and customize, compatible with user-friendly layout and editing software programs like Lightburn, and produce a highly focused laser beam that can handle engraving projects on a wide range of materials.

You can also control the height and intensity of the laser beam for etching your designs onto materials like wood, leather and some metals, and add detail with different tint and burn contrasts.

However, hobby diode laser cutters are much less efficient for actually cutting materials and working with thicker and harder materials in general. That’s because this type of laser cutter usually has a power output range of 5 – 10W, compared to 40W for standard desktop CO2 models.

But, if you’re looking for a low-cost and fun way to get started, these machines are a great option. Many of the popular, beginner-friendly diode laser cutters on the market are priced at less than $500. Let’s look at how they work.

How Hobby Diode Laser Cutters Work

This type of laser cutter uses laser energy that is generated by a semiconductor diode. The beam is then directed through a series of mirrors and lenses, which focus and collimate the beam to create a high-intensity, tightly focused laser (as accurate as .008 mm).

The laser cuts through the material by vaporizing it at the point of contact, creating a clean and precise edge.

Hobby laser cutters are usually designed with an open metal frame and a gantry controlled by CNC technology. The gantry travels along the y-axis, and the laser head moves along the x-axis.

Most also have an adjustable z-axis to control laser intensity according to design and material specifications. And some models also come with rotary attachments for working on products like mugs or tumblers

Compatible Materials

First, always check with the manufacturer to confirm which materials are compatible with your diode machine for engraving, etching and cutting.

Generally, this type of laser cutter can engrave the following:

- Plywood

- Cardboard

- Paper (i.e. 250g craft paper)

- Cotton

- Leather

- Non-woven fabrics

- Some plastics (check to ensure compatibility)

- Powder-coated and plated metals

You can also etch certain materials, including leather, stainless steel and aluminum. Some diode lasers can cut hardwoods, often with multiple passes and depending on the thickness.

Best For

These desktop diode models are best for crafters, artisans, DIY makers, and others who want a low-cost, high-tech, and fun way to transfer their designs onto durable materials like wood, metal, leather and acrylic.

You can create wood engravings for tools, ornaments, instruments, fashion items, etc., etch images and logos, create burn patterns, and much more. They are perfect for a home workshop or small design business too.

Examples

There are several well-known brands in this category, with lots of low-quality knock-offs on the market. So be careful and do your research.

Here are a few models we recommend based on reviews, features, and quality that suit a range of budgets

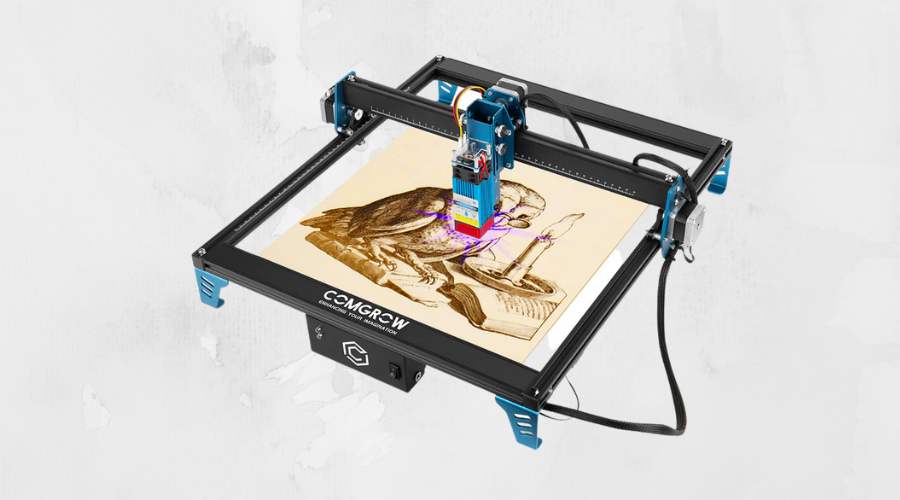

- Comgrow Z1 Diode Laser Engraver

- xTool D1 Pro

- Atomstack X7 Pro

- Ortur LM2 Pro S2

- Jinsoku LC-40 Laser Engraver

CO2 Laser Cutters

CO2 laser cutting machines have become the go-to type of laser cutter for many makers. These machines are powerful, easy to assemble, user-friendly, and come in a variety of sizes and price points for makers with different space requirements and budgets.

For example, there are well-known brands like Glowforge, OMTech, and Flux (beamo and Beambox)) offering desktop CO2 laser machines with 30 – 50W of power output, sleek designs, and advanced cutting and technology features.

Although they cost more than most entry-level diode models, CO2 lasers are much more powerful, still relatively affordable at this desktop size, and can cut a wider range of materials.

How They Work

Unlike diode and fiber machines, which are sold state laser cutters, a CO2 engraver uses a powerful beam of laser energy that’s generated by a mixture of gases, including carbon dioxide, nitrogen, hydrogen and helium.

The beam is directed through a series of mirrors and lenses before being focused on the material. CO2 lasers generate a visible infrared light with a long wavelength.

These machines range in power from 20 to 400+ watts (industrial models can be much higher, i.e 1 – 6kw) and can cut and engrave a variety of materials, including cloth, wood, some metals, coated glass, paper and more, by vaporizing the material at the point of contact and leaving a smooth finish.

Compatible Materials

Again, always check with the manufacturer first, but C02 models generally work best on thin organic materials like wood, paper, stone and fabrics, as well as many synthetic polymers and fabrics.

Here’s a summary of the materials you can use with most CO2 models:

- Wood

- Cardboard and Paper

- Fabrics and Textiles

- Acrylic

- Leather

- Bamboo

- Rubber

- Anodized metal

- Glass

- Cement

- Stone

- Stainless steel

Best For

CO2 lasers are a great entry point for makers, crafters, and DIY enthusiasts looking to experiment with laser cutting and even start their own business.

They do require a large investment than a basic diode open-frame laser cutter. However, if you have the budget, a quality CO2 engraver will work well for a variety of 2D and 3D crafting and design projects, including making fashion and home accessories, modeling for architecture and design, engraving designs for business customers (i.e. signs and packaging), and much more.

These machines also work great in schools, maker spaces, and other educational settings for creating large-format projects, experimenting with different materials and design software, and applying STEM concepts to their projects.

Examples

As mentioned, a few of the popular names in the CO2 laser cutter market are Glowforge, OMTech, and Flux.

Other high-quality examples include:

- Epilog Fusion Maker

- Universal Laser Systems

- Trotec Laser Cutters

- Boss Laser (i.e. the LS-1420)

- Thunder Laser (i.e. the Mini 60)

- Aeon Mira

Fiber Laser Cutters

So far, we’ve covered two types of laser cutters that work well for home workshops (although CO2 machines are often used in commercial settings as well). Our next type, the fiber laser cutter, is much more suited for an industrial cutting environment.

Fiber laser cutters are ideal for cutting, engraving, marking and etching metals, making them a popular choice for industrial and manufacturing applications. They are also well suited for cutting and engraving metals with intricate designs and patterns, such as jewelry and medical devices.

In addition to cutting and engraving, fiber laser cutters are also suitable for marking and etching metals, which is a process that involves removing the top layer of material to create a mark or design. This is commonly used for creating serial numbers, barcodes, and other types of identification marks on metal products.

They are much more expensive than entry-level CO2 or diode models but are low-maintenance and have a very long commercial lifespan.

How They Work

Fiber laser machines use high-power, solid-state laser technology. These machines pump light from a diode into a fiber optic cable, which creates and amplifies the laser beam.

This technology produces a stable and focused laser beam that allows for high-precision and high-intensity cutting through thick metals, such as steel, aluminum, brass, and more.

Material Compatibility

Fiber laser cutters work best with metals. Here’s a list of metals commonly used with these machines:

- Gold

- Aluminum

- Steel

- Titanium

- Brass

- Copper

- Silver

Best For

Fiber laser cutters are ideal for industrial and manufacturing applications where cutting, marking and etching metals is a priority. These businesses either require high production output or need to meet demanding customer specifications in automotive, medical, consumer packaging and other commercial settings.

While there is a large upfront investment, fiber laser cutters are known for their long lifespan and low maintenance requirements.

Examples

Some of the brands mentioned in the CO2 section also produce fiber laser cutters, such as the FC-6012 from Boss, the Fusion Series from Epilog, and the OMTech FC series.

Other well-known manufacturers of fiber laser cutters include:

- Amada

- Bystronic

- Prima Power

- Heatsign marking machines

- Mecco fiber laser marking systems

- IPG Photonics

- Laguna tools, and more.

Other Types of Laser Cutters

In addition to the three main categories we’ve covered, there are a couple of other types of laser cutters worth mentioning.

Nd:YAG lasers

Like fiber lasers, Nd:YAG laser cutters are another type of laser cutter used for high-precision metal marking and engraving applications. This laser technology relies on a diode laser that’s pumped through neodymium ytrium-aluminum garnet crystal, creating a very precise and high-intensity laser beam.

Nd:YAG lasers produce a wavelength that’s 10x smaller than CO2 lasers and still more powerful than fiber laser cutters.

These are very expensive machines, however, with a shorter lifespan and more maintenance requirements compared to fiber laser cutters. As such, you’ll find these laser cutters mostly used in high-precision metal marking and applications for medical devices, metal tool engraving, micro-machining, and automotive manufacturing.

Combination Laser Cutters (3-in-1)

Just like it sounds, 3-in-1 machines combine the benefits of three separate technologies in one machine: laser cutter, CNC router, and 3D printer. While these do not offer anything unique in terms laser cutting technology, they are a cool option for makers since they can perform both subtractive and additive processes.

Of course, if you are focused on creating designs with a laser cutter, I wouldn’t recommend using a combination unit versus a traditional engraving machine. But if you want to dabble in different processes and build both 2D and 3D designs, it’s worth checking out.

The most well-known brand in this 3-in-1 category is Snapmaker, with several modular machines that combine 3D printing, laser cutting/engraving, and CNC carving.

Portable Laser Cutters

Finally, a new breed of laser cutters that’s emerged in recent years are portable laser engravers. These are plug-and-play models that can cut and engrave and a surprisingly wide range of materials with lower power output and very compact designs. If you want to take your maker show on the road, these are pretty cool.

The LaserPecker 2, which uses compressed diode laser technology, is perhaps the most popular model in the portable category. And now, with the LaserPecker 3, you can harness the power of fiber optic laser cutting for metals in a portable format.

In terms of price, these higher-quality portable laser engravers fall in between hobby diode models and desktop CO2 brands.

Wrapping Up

Hopefully, after reading this guide, you can find the right type of laser cutter for your specific needs. Of course, you’ll need to consider your budget, workshop space, power requirements, material compatibility, the types of projects you want to make , and more.

Check back for more helpful guides focused on laser cutting and other topics for the maker community.