Manufacturing is heavily dependent on technology. One example that has been driving innovation and efficiency is fiber laser cutting.

While fiber laser cutting was developed in the 1960s, it was only in the early 2000s that it began to be used in manufacturing.

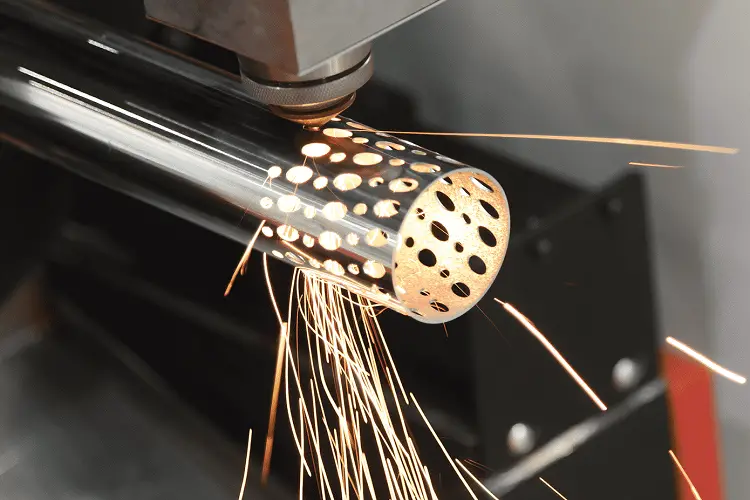

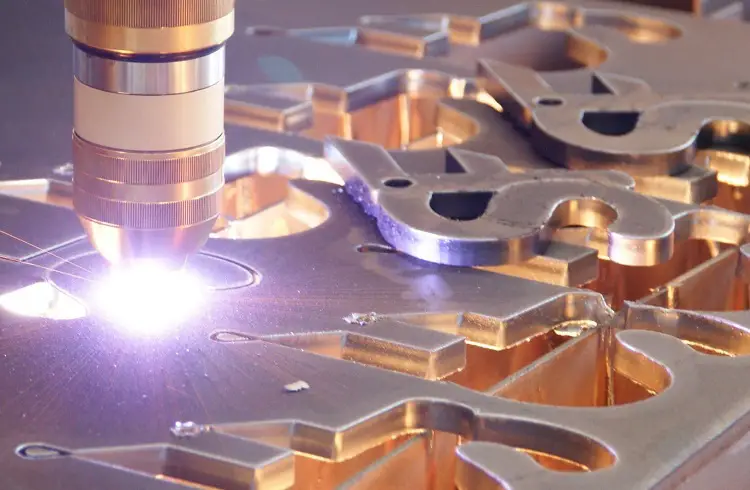

This cutting technique relies on a powerful fiber laser beam to achieve highly precise and accurate cuts. It employs a solid-state laser that can cut through different kinds of materials like metal and plastics and turn them into different shapes and sizes.

Because of its many applications, fiber laser cutting has become immensely popular across industries, particularly in the metal cutting industry. More and more manufacturers involved in metal fabrication are adopting the technology to achieve greater productivity, production speed, and product quality.

If you’re looking to adopt this cutting-edge technology in your business, we’ll tell you all about fiber laser cutting, its uses, average cost, and what makes it different from conventionally used CO2 lasers. Read on.

What Is Fiber Laser Cutting?

Fiber laser cutting is a hot cutting method that can pierce through different materials with the help of a focused laser beam using a high-power density setting.

It uses the laser beam as the main heat and light source to provide intense heat and illuminate the workpiece. The heat and light are delivered to the cutting head through a fiber optic line for effective transmission.

This process causes the material to melt, evaporate, or reach the ignition point rapidly. It also uses a powerful flow of gases at high speed to prevent the material from overheating while blowing away the molten or vaporized pieces. This helps achieve greater precision and finesse in cutting.

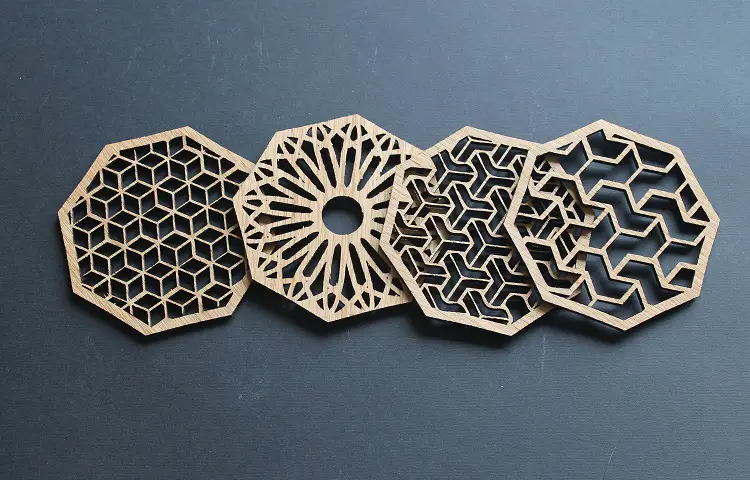

Fiber laser cutting offers a significant level of control during the cutting process. While cutting, you can control the heat, gases, gas pressure, and so on. This helps manufacturers create intricate objects of any size or shape using materials with different densities.

Fiber laser cutting provides a host of other benefits such as rapid cutting speed, high accuracy, and low costs. Fiber laser cutters are relatively maintenance-free which makes them preferable over other cutting machines.

Its benefits and wide range of applications have made the technology exceedingly popular in recent years, making it a hot topic in the manufacturing industry.

They are now commonly used in sheet metal processing, electronics, electrical appliances, automobiles, aviation, aerospace, ships, construction machinery, metallurgical equipment, and other manufacturing and processing industries.

How Thick Can a Fiber Laser Cut?

The laser power of a fiber laser cutting machine determines its cutting thickness.

For example, a 1,000 watt fiber laser cutter will have a maximum cutting thickness of 20 millimeters for carbon steel, 10 millimeters for stainless steel, 8 millimeters for aluminum, and 6 millimeters for yellow copper.

A 3-kilowatt fiber laser cutting machine will have a maximum cutting thickness of 22 millimeters for carbon steel and 12 millimeters for stainless steel and aluminum.

Meanwhile, a 6-kilowatt fiber laser has a maximum cutting thickness of 25 millimeters for carbon steel, stainless steel, and aluminum and 12 millimeters for yellow copper.

The thicker your material, the more powerful your fiber laser cutter needs to be.

What Is the Difference Between a CO2 Laser and a Fiber Laser?

Manufacturers often get confused between choosing between a CO2 laser and a fiber laser.

In this section, we’ll tell you about their differences so you can make the right call:

Source of Laser Beam

One of the main differences between a fiber laser and a CO2 laser is how the laser beam is created.

In fiber lasers, the source of the laser beam is a mixture of silica glass and a rare-earth element. In CO2 lasers, the laser is created with a blend of gases such as carbon dioxide, oxygen, nitrogen, helium, and hydrogen.

Due to the source of the laser beam, fiber lasers are viewed as solid-state lasers while CO2 lasers are considered gas-state lasers.

Wavelength Range

The wavelengths produced by fiber lasers and CO2 lasers also differ. Fiber lasers create shorter wavelengths of around 780 nanometers to 2,200 nanometers. Meanwhile, CO2 lasers have longer wavelengths ranging between 9,600 nanometers and 10,600 nanometers.

Materials

Fiber laser and CO2 lasers work best on different materials and are suited for different purposes.

CO2 lasers have an advantage over fiber lasers since they can cut a wide range of organic (non-metallic) materials and also certain metals.

However, they require a lot of power (watts) to cut metals. For instance, you’ll need a CO2 laser machine with about 300 watts to cut steel. CO2 lasers also need oxygen to cut metals.

Remember that CO2 lasers can’t cut all kinds of metals, particularly highly reflective ones. Highly reflective metals like aluminum, copper, brass, gold, and silver tend to reflect or throw back a huge amount of laser or light. This can damage the CO2 laser machine and cost you thousands of dollars in repairs.

Some of the materials that CO2 lasers can cut include wood, acrylic, plastic, cork, rubber, stone, brick, fabric, paper, fiberglass, leather, melamine, marble, tile, painted metals, and anodized aluminum.

On the other hand, fiber lasers have a shorter light wavelength of around 1 micron, making them ideal for all kinds of metals. In addition, the laser beams of fiber laser machines have a lower frequency. Unlike CO2 lasers, this allows them to easily absorb light without getting damaged by highly reflective metals.

However, a fiber laser machine isn’t suited for certain organic or non-metallic materials. For example, if it is used on oily wood, the wood can catch fire. Using it on some types of plastics may melt them.

Cutting Speed

Fiber lasers are usually about 5 times faster than CO2 lasers when it comes to cutting thin metals with a thickness of up to 5 millimeters or ¼ of an inch. A 2-kilowatt fiber laser machine can cut thin metals as quickly as a 5-kilowatt CO2 laser machine.

This is because the laser beam of a fiber laser machine has a short wavelength which allows it to be absorbed more easily by the metal that needs cutting. It also has a high-power density that allows it to cut through thin materials like a knife cuts through soft butter.

On the other hand, CO2 lasers fare better at cutting thicker metals that are at least 5 millimeters thick. Their longer wavelengths allow them to cut through thick metal more efficiently and quickly than fiber lasers.

CO2 lasers are also faster than fiber lasers when it comes to jobs that require the same straight cuts as they usually have a quicker piercing time. This helps deliver faster turnarounds.

Cutting Quality

Fiber lasers provide incredibly clean and sharp cuts for thin metals, making them a popular option for cutting sheet metals up to 5 millimeters thick. However, they fail to deliver consistently accurate cuts as the thickness of the material increases.

CO2 lasers are the preferred choice for thicker metals as they provide a better edge quality and a more polished finish than fiber lasers.

However, take note that nowadays, fiber lasers are also getting better and can deliver a clean, precise cut even for thicker metals.

Power Consumption

Fiber lasers are more energy-efficient than CO2 lasers. They need only about a third of the power used by CO2 lasers to achieve the same results. If you follow or wish to adopt green manufacturing standards, you might want to stick to fiber lasers.

Cost

The initial cost of fiber laser machines is usually higher than CO2 laser machines even if they have the same features like speed, power (watts), size, etc. However, in the long run, fiber lasers are better.

This is because CO2 laser machines cost more in the long term as they require more consumables, power, maintenance, and repair. They also have a shorter service life compared to fiber laser machines and need to be replaced every 10 to 15 years while fiber lasers can last 2 or 3 times longer.

Size

Fiber laser cutters are usually smaller than CO2 lasers since they don’t have aligned mirrors and complex equipment that contain and transport gasses. On the other hand, CO2 laser machines need gas storage tanks, pumps, pipes, and other paraphernalia that can take up a good amount of space in your factory or plant.

If you’re looking to save space, get a fiber laser cutter. It’s more compact and requires less space than CO2 laser machines.

Safety

Fiber lasers produce a wavelength that can be extremely harmful and can cause severe damage to your body and eyes, especially in the long term. You need to use adequate safety measures including eye protection when using them.

While CO2 lasers are less dangerous, they can still cause harm.

Make sure you always wear adequate protection for your eyes and follow other safety measures for operating laser machines.

What Material Can Be Cut With Fiber Lasers?

As mentioned, fiber lasers work best with metals, including highly reflective ones owing to their shorter wavelength.

They can also be used to cut other materials aside from metals with a high level of precision by programming the laser beam. All you need to do is tweak the cutting gas, gas pressure, laser power, and nozzle.

Let’s take a look at some of the materials that fiber lasers can cut:

- Aluminum

- Brass

- Copper

- Stainless steel

- Carbon steel

- Silver

- Gold

- Titanium

- Tungsten

- Nickel

- Chrome

- Coated and painted metals

- Carbide

- Non-semiconductor ceramics

- Glass

- Diamonds

- Graphite composites

- Silicon

- Pewter

- Non-oily wood including plywood and medium-density fiberboard (MDF)

- Rubber

- Plastics like acrylic, polymethyl methacrylate (PMMA), polyoxymethylene (POM), and Lucite

- Paper and cardboard

Note that the absorption range of certain materials doesn’t match the wavelength range of fiber lasers. You should avoid using fiber lasers for materials like:

- Oily woods

- Leather

- Fabric

- Stone

- Glass fiber

- Carbon fiber

- Acrylonitrile butadiene styrene (ABS) plastic

- High-density polyethylene

- Polycarbonate

- Polyvinyl chloride

- Polystyrene

- Polypropylene foam

How Much Does a Fiber Laser Cutter Cost?

The cost of a fiber laser cutter varies from seller to seller, but it also depends on whether you’re buying a new or used one.

The price of high-end fiber laser cutters ranges between $40,000 and $600,000. It may seem expensive, but it is less costly than other types of laser cutters in the market. You can also save a lot by buying a used machine.

Moreover, you’ll find the investment worth it not only because the machine delivers superior cutting precision but also because it saves money on power consumption and maintenance.

Fiber laser cutters have a relatively lower operational cost than other laser cutters at around $4 per hour, making them a cost-friendly option for businesses.

How Long Do Fiber Lasers Last?

Fiber lasers cutters enjoy a superior life expectancy as their diode module can function three times as long as other laser cutting technologies. With fiber lasers, you can expect a service life of around 100,000 hours.

However, fiber laser cutters may result in fabrication errors and failures during their service life so be prepared.

Make sure you have a purchase guarantee that covers fabrication errors and failures. If the laser cutter fails early on, you can replace it at no extra cost.

Once the machine enters its normal life or is no longer new, it’s good to have a spare laser cutter just in case. You can also get an extended purchase guarantee to prepare for mid-life machine failures.

Conclusion

Fiber laser cutting is a boon to manufacturers as it helps them cut thin metals with great precision. It also results in faster production, high-quality cuts, rapid cutting speed, long-term cost savings, low maintenance requirements, power and space savings.

It also has a wide range of applications that makes it suitable for different industries and materials while having a long service life.

If you’re in the manufacturing or processing industry and your operations require you to cut thin metals and other materials, consider getting a fiber laser cutting machine.

We hope you enjoyed this article and that we’ve helped you decide on whether or not you should use fiber laser cutters for your business.