These days, it’s never been easier to create highly customized pieces from a wide array of materials. Modern technology like laser engraving enables creators to imprint virtually any surface design. However, while this process is useful for different purposes, it doesn’t work for all materials.

One question you might ask is, “can you laser engrave stainless steel?” Let’s dive into this topic and find out.

Technically, you shouldn’t laser engrave stainless steel, as doing so will remove the protective layer of chromium oxide. That said, if you take certain precautions, you can achieve the best results without ruining the metal itself. Another option is laser annealing, which doesn’t remove any protective elements.

What is Laser Engraving?

In the old days, if you wanted to engrave a piece of wood or metal, you had to do so by hand using specialized tools.

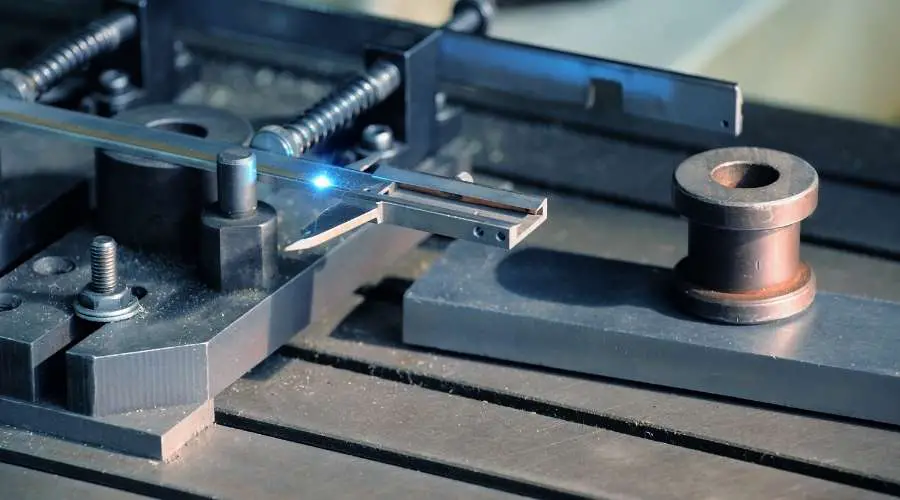

Laser engraving kicks this process up a notch by using high-powered lasers to achieve the same results. What’s incredible about laser engraving is that it doesn’t leave behind residue or shavings the same way as chiseling does. Instead, the laser superheats the material so that it turns into a gas.

The purpose of laser engraving is to create a long-lasting surface cut. This process is different than etching, which only removes a small layer to get similar results.

Laser Engraving vs. Marking Stainless Steel

Technically, marking a material means that you either engrave, etch, or anneal the surface. As we mentioned, engraving is not ideal for stainless steel. Etching can also remove too much chromium oxide, so you should only use laser annealing to mark the surface.

Laser annealing works by heating the metal to the point of changing its color. This process is far less extreme than laser engraving because it doesn’t actually remove any material. Instead, it just leaves a permanent mark, which is why it works so well for stainless steel.

When Would You Need to Laser Engrave Stainless Steel?

There are many reasons why companies need to mark stainless steel products and components. Some of those reasons include:

- Traceability – Some products, like medical equipment, need to be traced from the manufacturer to the final delivery point. This way, if there’s an issue with the piece, the user can contact the manufacturer. Examples of traceable elements include ID codes, contact information, or QR codes.

- Barcodes – Engraving a barcode onto a stainless steel part works better than using a sticker or other material.

- Logos and Designs – If you want to produce branded swag (i.e., a stainless steel mug or flask), laser engraving allows you to create more complex designs.

Tips and Tricks for Laser Engraving Stainless Steel

If you’re going to laser engrave stainless steel, you have to be careful to avoid rust and corrosion in the long term. Here are some ways to get the best results:

- Make Multiple Passes – Technically, you can finish the design in one pass, but you might wind up with residue inside the engraving. This residue makes the design look worse, and it can cause metal shavings to come out in transit. Instead, you should make many passes to avoid this problem.

- Engrave From Bottom to Top – Doing this helps alleviate the smoke issue, as the smoke can get pulled away from the laser while it’s working.

- Test Your Designs First – Before doing a final run of a new design, engrave some scrap stainless steel first to see how it looks. Doing this can save you from expensive headaches later on.

- Know the Limits of Laser Engraving – Since this process makes deep cuts into the metal, it’s not suited for intricate logos or designs. If you want something more complex, you’ll need to switch to laser etching or annealing.

- Treat the Surface Afterward – Because you’ll wind up removing the chromium oxide layer, you need to protect the metal from rusting. You can do this by adding protective oils and products to the surface. Keep in mind that you’ll have to reapply these elements regularly, depending on how the metal is used.

Best Machines for Laser Engraving Stainless Steel

Since stainless steel is resilient, you need a high-quality laser engraver. Here are some excellent options for marking this type of metal:

- Snapmaker 3-in-1 – This machine is the ultimate accessory for your workspace. Not only can it engrave metals and other biological materials, but it can also work as a 3D printer and CNC machine. That said, the Snapmaker 3-in-1 is not built for high-end or industrial applications. It works best for smaller projects.

- MakeBlock Laser Engraver – As you’ll notice, most at-home laser engravers and etching machines are built to work with wood. However, this model from MakeBlock can do well with thin stainless steel pieces. Keep in mind that you’ll have to run the machine for a lot longer to achieve your results, so plan accordingly.

- MathRose A5 Laser Engraver – Like the MakeBlock model, this engraver is best for wood and plastic, but you can also use it for stainless steel applications. That said, the laser on this machine is denser than most others, so it works a bit faster and more efficiently overall.

Can You Laser Engrave Stainless Steel With a GlowForge?

Yes, you can create designs on stainless steel with a GlowForge. However, because this machine uses a CO2 laser, you need to coat the surface with a product like CerMark. CerMark bonds with the metal and allows the laser to create etchings and designs on it rather than the metal itself.

The results are similar, but you won’t cut through the metal as you would with etching or engraving.

The Glowforge Plus is an excellent plug-in-play laser cutter. Prepare to get your creative juices flowing because this beauty is also a cutting beast.

So, technically, no, you can’t laser engrave stainless steel with a GlowForge because the laser is not powerful enough.

Fiber vs. CO2 Machines for Laser Engraving

When marking different material surfaces, you can choose between fiber or CO2 lasers. Here’s a quick breakdown of how these two machine options stack up.

Price: Industrial-strength fiber lasers are the most expensive because they deliver the best results. However, if you’re buying an at-home laser etching and engraving system, you can find comparable prices between both options.

Power Requirements: CO2 lasers need extra electricity because of their etching and engraving process. So, you can expect a higher utility bill if you’re using a CO2 laser often.

Materials: Laser engravers can work on virtually all surfaces, although they’re not made for biological elements or plastic. CO2 lasers are much better for marking plastic, glass, or textiles because they won’t damage the material.

Maintenance: CO2 lasers will need refilling because they use concentrated carbon dioxide during the printing process. So, you have to buy more gas regularly to keep your laser working properly. Fiber lasers don’t need as much upkeep, and they last a lot longer.

Overall, if you’re working with stainless steel, you need a high-quality fiber laser. Although CO2 lasers can mark stainless steel when combined with products like CerMark, the results are not as intense.

FAQs About Laser Engraving Stainless Steel

Can I prevent my stainless steel from rusting after I engrave it?

Realistically, the best option is to passivate the metal, meaning that you add a layer of citric or nitric acid to the surface. Passivation removes free iron from the metal and forms a protective coating. You will need to use high-quality acid and bathe the piece entirely for it to work. You can buy citric acid products online.

Should I laser-engrave my stainless steel parts?

If you want to avoid the hassle of passivation or preservation, it’s better to use laser annealing instead of engraving. Also, you can often get more complex designs through annealing than you could with engraving.

Do I need to smooth my stainless steel after engraving?

Sometimes, the engraving process can leave sharp edges, so you might have to use a buffer to smooth those out. After you’re done engraving, run your fingers over the design to detect any points or burrs.

Overall, while it’s possible to laser-engrave stainless steel, doing so might cause adverse reactions. Before committing to your project, make sure that engraving is the best option. Otherwise, you can utilize other marking processes like annealing or use a CO2 laser with an added surface layer (i.e., CerMark).