Although cost is an essential factor to consider when looking for the best technology for your 3D printing, performance is also significant and should be taken seriously.

The drive system will determine the technology with the two significant comparisons being belt vs. lead screw 3D printer technologies.

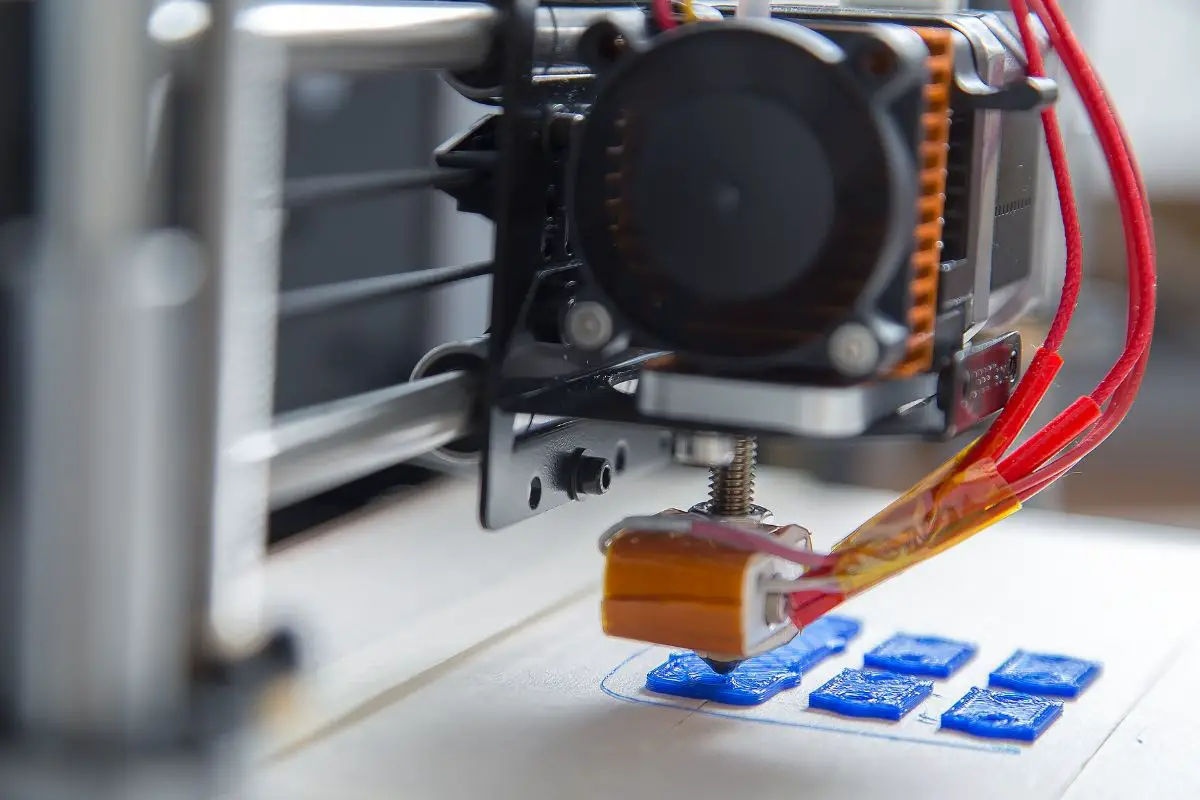

Belt-driven 3D printer

It’s common for those who want to venture into 3D printing to ask what is a belt-driven 3D Printer since it is one of the commonly used printers.

Its functionality is often comparable to that of a conveyor belt system since it involves the use of a timing belt and pulleys.

Both the timing belt and pulleys have teeth with the former being connected to a moving carriage, and the latter connected to a motor shaft that pulls the pulley to direct the belt in one direction.

Different materials can be used to make the belt, but the common one is an elastomer, which is reinforced by fiber, while the belt drive is shielded with aluminum.

Lead screw 3D printer

What is a lead screw 3D Printer is another common question since the printer is often compared to the belt driven option.

This type of printer has improved performance, which comes from the fact that it combines a linear spindle with a rotary motor.

The lead screw technology is different from the ball screw technology even though either of them can be used in the screw-driven printers.

The printer is less expensive than a belt-driven printer, but it is just as efficient and can deliver on performance.

Pros

When comparing the two printers, Pros and Cons must also be considered.

- Belt-driven 3D printers are easier to maintain since they don’t have to be lubricated frequently over time. This means that they can be used for prolonged periods, and they won’t break down or lead to incurring maintenance expenses.

- Another benefit of these printers is that they are easier to integrate with other systems. Their adaptability means that you don’t have to worry about changing your entire set up to use them. You can add them to the system you already have, and they function well.

- Belt driven 3D printers also have a compact design which helps with durability. This is one of the reasons why they are better suited for longer travel lengths, and they still function at high speed.

Cons

- One of the disadvantages of belt-drive 3D printers is that their belts are susceptible to stretching, which can affect production.

- Lead screw printers, on the other hand, can be easily misaligned, and the backlash can increase as the printer is being used. They can also wear off quickly, leading to more expenses for you.

Cost

The cost of the printer differs from every brand, but the belt-driven printers are a little more expensive than the lead screw printers.

Which is better?

When it comes to which is better, they both have their advantages and disadvantages that you must consider before making a choice.

Each person’s preference is determined by their needs and how well the printer performs in the specific environment they are used in.

On the downside, belt-driven printers can require higher loads when the belts are thicker, in which case the lead screw printers are better.

However, the latter also has duty cycle limitations, which are usually at 50%, which makes the belt-driven printers a better option. You should, therefore, consider your specific needs when making your decision.

Related: Best 3D Printer Under $1000: Ultimate Buying Guide

Summary

We hope this gave a clearer understanding of the belt vs lead screw 3D printer debate.

Belt driven printers are the better choice if you have smaller loads, but you need faster operational speeds. They are also better if you require long strokes but want to operate on a budget because of their cost-effectiveness in such applications.

Lead screw printers are the better option if you have high loading, which in turn requires high loading forces. They may be more challenging to install and less efficient, but they also have more accurate positioning.

Based on these, the better printer will be the one better suited for your specific application.