The quick answer is yes; you can cut glass with a laser cutter.

However, there is much more to this than meets the eye.

Your typical hobby laser cutter won’t likely be equipped to cutting glass. If that’s your situation, then we would recommend engraving tempered glass or acrylic.

So, let’s rephrase the question from can you cut glass with a laser cutter to what kind of cutter you need to do it.

Right off the bat, some at-home cutters handle glass with ease. But then, it depends on what type of glass you use.

Of course, the cutter’s specifications also play an essential part. So, this write-up takes an in-depth look at all the requirements to slice through glass like it’s butter.

What Types of Lasers Are Good for Cutting Glass?

You are likely to stumble upon one of the two common types of laser cutters − pulse or continuous wave. Each one has its characteristics. Thus, it pays to take a closer look.

Pulse lasers compress the cutting energy into short bursts. That allows the machine to reach a high temperature and energy density. In turn, you get less deformation and high-precision cuts.

But to achieve the pulse, these units have high-end electronics and materials, which makes them more expensive than continuous-wave.

As given in the name, continuous-wave lasers deliver an unobstructed flow of energy to cut. The glass gets heated until the material literally evaporates, but this might cause deformation with some types of glass.

Laser Cutter Wavelength

Can you cut glass with a laser cutter? The answer to this question wouldn’t be complete unless you consider the laser wavelength.

To begin with, you can’t cut glass with a wavelength within the visible spectrum. Since most types of glass are clear, they absorb little energy from the given range. That said, glass with some natural pigment might be cut with a visible-spectrum wavelength, and there are other exceptions.

For example, if the laser is so powerful to ionize the air, a high-focus beam can overheat the air around the glass and cause it to crack. That yields the effect of marked glass but is still not the best choice for cutting.

Getting the Right Wavelength

The ideal wavelength is usually 10,600 nm. That is, you need a CO2 laser that can produce infrared light. In a setup like this, about 80% of the light gets absorbed by the glass’ Si-O bond.

Another effective wavelength falls above the UV spectrum at 355 nm. The advantage of this wavelength is that it works great for smaller areas. As a result, the glass will suffer less thermal effect, and you can avoid cracks.

However, laser cutters with UV capabilities are mostly for industrial applications. And the ones with infrared light capabilities belong to the design-level and consumer category.

Different Types of Glass

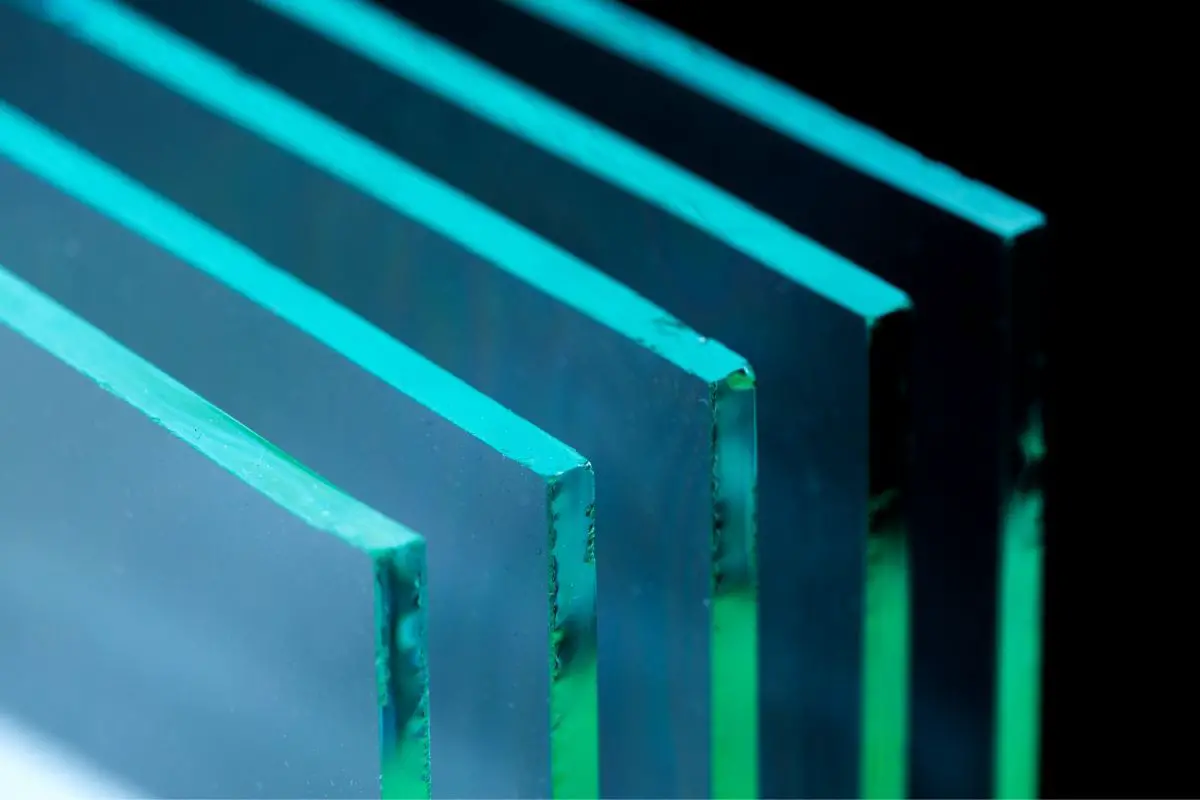

About 90% of glass is obtained through the float glass process, and this method yields the so-called soda-lime glass. The process involves floating molten glass on another liquid material, usually metal. Other common glass types are:

- Borosilicate or lead

- Fused silica

- Stained

- 96% silica

- Aluminosilicate

Also, there are special types of glass which undergo heating and cooling to make them safer. But this glass can’t be cut with a home laser cutter.

So which kind of glass is ideal for laser-cutting?

If you run a small studio or workshop, it’s best to go for soda-lime float glass.

The properties of this material make the process straightforward, and it reduces the trial and error.

It’s worth noting that other kinds of glass usually require specific preparation and professional tools. That’s because other types are engineered for exceptional heat resistance and thus have a much higher melting temperature.

Key Glass Cutting Considerations

Assuming you’ve settled with the soda-lime float glass, there are other properties of this material you need to consider.

The first thing to factor in is the glass thickness.

Simply put, the thicker the glass, the harder it is to cut it. Depending on the machine you have, you might need to make several passes. And some units require laser focus adjustments to ensure it goes all the way through.

Next is cutting precision. If you need to make several passes, the cut dimensions suffer. Therefore, it’s best if you can do everything in two, maybe three passes to minimize discrepancies and waste.

And what the machine can do in a single go depends on the laser properties. You should be able to find this information in the cutter manual.

Lastly, there’s always the question of breaking the glass. Several passes may cause thermal expansion and cracks or even break the glass as it cools down. To avoid this, test out the limits of the machine before you begin cutting for commercial projects.

Safety Concerns

Laser cutting is generally safe for you and the environment. But there are specific safety guidelines you should always keep in mind.

Wearing goggles that block out the wavelength you’re using is crucial. At best, this piece of protective gear should have an optical density (OD) of 3+ or higher. That prevents UV and infrared wavelengths from reaching your eyes.

With this in mind, you should never look at the beam directly, even if you have the glasses on. Your arms and legs should be away from the laser beam as well. And the same goes for any other foreign object or material.

It’s also advisable to wear protective gloves to avoid cuts and burns. As you already know, some laser cutters have a transparent plastic window to view the progress while the machine is in operation. It absorbs a lot of the CO2 light, and it’s safe enough to take a quick look.

However, protective goggles are still a must. A single stray beam is enough to cut through the plastic, so you need secondary protection to avoid injury.

Finally, your laser cutter requires proper ventilation, and some units come with a special pipe that you can hook up to an external ventilation system.

Cut Glass Like There’s No Tomorrow

Can you cut glass with a laser cutter? The answer is yes, and you need to zero in on the correct wavelength to do it.

Other than that, you should know the glass properties and wear protective gear at all times. You may also be interested in laser engraving tempered glass.

The hardest part, however, is coming up with cool designs that can take your laser cutting to the next level!