Acrylic is a versatile and reliable material that works well for many DIY and professional projects.

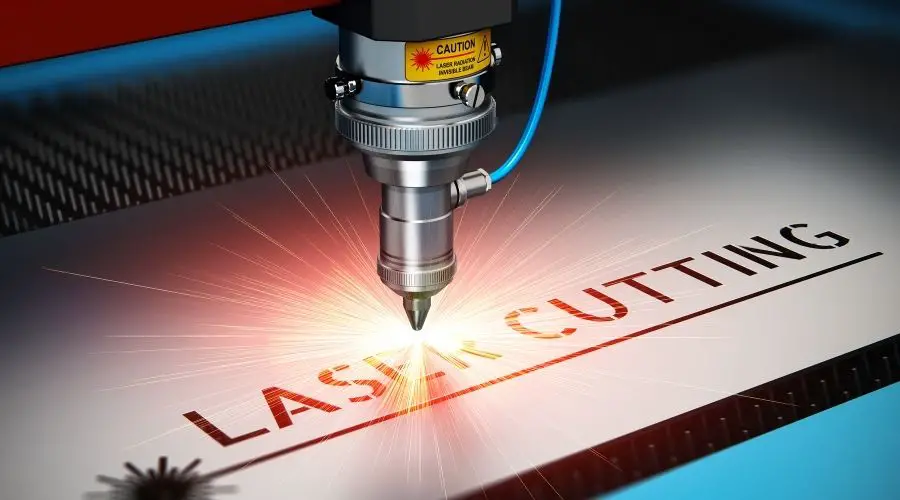

When you want a plastic-like material that holds up to environmental conditions and abuse, acrylic is an excellent choice. But, the question is, can you laser cut acrylic?

Yes, you can laser-cut acrylic. However, there are two different types of acrylic material, so the one you choose matters. Extruded acrylic is the best for laser cutting because it creates a flame-polished edge.

Cast acrylic, however, doesn’t work for laser cutting, but you can use it for laser engraving. We’ll discuss these types more in-depth later on.

Can You Laser Cut Acrylic?

There are two basic types of acrylic material – cast and extruded.

Extruded acrylic works well for laser cutting since it holds its shape better and offers a clean edge. By comparison, cast acrylic can be a bit messier, so it works best for engraving instead.

Another benefit of engraving cast acrylic is that it creates a frosted glass appearance.

Another point to consider is that you can cut and shape cast acrylic with other tools, such as saws and drills. Just because laser cutting isn’t ideal doesn’t mean you can’t use cast acrylic for your project.

Related questions:

- Can you cut glass with a laser engraver?

- Can you laser engrave tempered glass?

- Can you laser cut epoxy resin?

Types of Acrylic for Laser Cutting

Acrylic is a thermoplastic material that is both transparent and shatter-proof. Many manufacturers use acrylic to replace glass in various designs and products. Because acrylic is so versatile and reliable, you can find it in various industrial and commercial applications.

We’ve mentioned the two acrylic types, but let’s break them down further so that you can understand how to use them in your designs.

Extruded Acrylic

In this case, manufacturers will force the raw resin material (methyl methacrylate) between two steel dies to form one large continuous sheet. This production method ensures the acrylic stays stable, even when laser cut.

Typically, extruded acrylic is formed into giant sheets and then cut into standard smaller sizes.

If you’re looking for commercial brands of extruded acrylic, some names include Deglas, Optix FG, Homalite, and Solatuf.

Cast Acrylic

Rather than forcing the raw resin between steel dies, cast acrylic works by pouring the resin into a metal mold.

Once the material hardens, it can be cut into smaller sheets. This acrylic type doesn’t work well for laser cutting because the resin won’t cut cleanly. Instead, it can have a rough, uneven edge.

While you could smooth out the edges with sandpaper or something similar, there’s no reason to add extra work to your project.

Commercial brands of cast acrylic include Lucite, Hesa Glas, Shinkolite, and Acrylite.

Here’s a video to watch explaining the difference between cast and extruded acrylic as it applies to laser cutting:

Tips and Tricks for Cutting Acrylic

Although acrylic is a durable and versatile material, you have to fine-tune your work to get the best results. Otherwise, you might wind up with uneven edges, a frosted glass appearance, or other issues.

Here are some points to consider before starting on your project:

Elevate Your Acrylic for Cutting

Laser cutting is much different than laser engraving.

When cutting, you’re trying to extract pieces from the main sheet. One way to ensure cleaner results is to elevate your acrylic. You don’t have to lift it too high from the cutting surface; a 1/2 inch or less will be more than enough.

Otherwise, you might have to worry about overheating once the laser hits the backing, causing bumps and other imperfections.

Related: How to clean acrylic after laser engraver.

Use Proper Ventilation

As with other plastics, acrylic creates fumes when heated.

Fortunately, the fumes are not highly toxic, so acrylic is generally regarded as safe for laser cutting.

That said, it’s always a good idea to have vent hoods and fans in your workspace. You might also want to wear a filtered mask when cutting if you’re going to be close to the machine.

Reduce Your Air Assistance

Air assistance means that the cutter blows a steady stream of compressed air to help keep the material from overheating.

Unfortunately, this process means that you’ll get the frosted glass effect. If you’re engraving your acrylic, an air assist system can be beneficial.

For cutting, though, it may deliver unsatisfactory results. Most budget laser engravers do not have an air assist feature, although some do.

Keep Your Lens Clean

Another side effect of high air assistance is that it keeps the lens clean because the air blows off any debris or particles while the machine is operating.

So, by reducing your air assist, you’ll have to clean your lens more often. So, if you’re making large batch orders, you should plan for breaks to clean the lens between batches.

If your lens stays dirty, the laser could refract and create uneven cuts. Overall, you’ll notice the quality drop dramatically the longer you go between cleanings.

Adjust Your Beam Focus

One mistake that many newbies make is that they point their beam at the surface of the acrylic – either the top or the bottom.

Unfortunately, this means the beam won’t be even during the entire cut, so you can wind up with distorted edges.

Instead, it’s much better to focus the beam in the center of the material. So, if you’re cutting 6 mm acrylic, you can put your beam at the 3 mm mark.

Check Your Wattage

Laser cutters need more electricity to cut through thicker material. As a rule, you should have at least 10 watts per millimeter of acrylic.

So, if you’re cutting a 5 mm sheet, you should have at least 50 watts. That said, this rule is more of a guideline, meaning that it’s often better to have more power available than less.

If you’re unsure how much electricity you need, do a test run to see the results before making your first “official” cut.

Set the Right Frequency Parameters

Laser cutters work by concentrating light at high frequencies. So, to ensure smoother results and edges, you must use the right frequency level.

As a rule, your frequency should be at least 5,000 Hz. If you’re cutting GS materials, the frequency can go as high as 20,000 Hz.

Again, it might be a good idea to practice on your material before committing to your settings.

If the frequency is too low, you’ll notice small “chatter marks” on the surface, leading to a rough and messy edge.

Mirror Your Work for Engraving

Acrylic is also highly popular for laser engraving because it offers such a dynamic illustration. When engraving acrylic, remember that you’re cutting it from the back of the material, not the front.

Engraving this way ensures the best results because the surface will be clean and smooth, not rough.

So, when setting up your machine, you have to mirror your design. Otherwise, it will appear backward when showing off the final piece.

Fortunately, many laser engraving programs have a mirror option built-in, so all you have to do is click a button. Otherwise, you need to mirror the design before sending it to your cutter.

Avoid Intricate Designs

Whether you’re engraving or cutting acrylic, one factor to consider is the material’s transparency.

Since it doesn’t have an opaque surface, it can be harder to see the edges. So, if you have complex or ornate engraving designs, they can be hard to make out when you have the final product.

Likewise, lettering and writing can be especially hard to read.

When laser cutting acrylic, small pieces can break more easily, particularly if you’re using thin sheets. As a rule, acrylic works best for simple designs and lettering.

The Bottom Line

As you can see, laser cutting acrylic is a process that requires a bit of fine-tuning. While this material works well for laser cutting, you have to prepare your designs and machinery beforehand.

Now that you know the basics of laser cutting acrylic, you can make your next project shine. Happy cutting!