There are a number of different reasons why it is important to dry filament during 3D printing.

One of the most important reasons is that you can improve your print quality by drying filament. It’s possible that you haven’t dealt with too many issues even if you don’t dry your filament on a regular basis.

However, that is usually only the case if you quickly complete your filament rolls.

The longer you take to do this, the more likely it is that not drying the filament will become an issue.

The main benefit of drying your filament is that you will notice an improvement in the consistency of your 3D printing results.

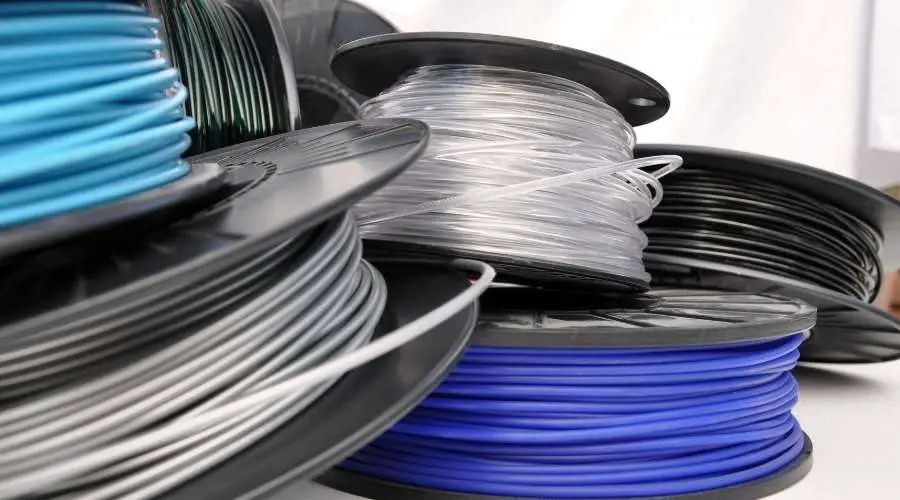

One thing that you should know is that the majority of filaments that are used during 3D printing are known as hygroscopic.

Simply put, hygroscopic means these filaments absorb some of the air’s moisture and tend to lose some properties as a result of doing so.

As you might expect, some of the filaments that you can use are more hygroscopic than other filaments.

Nylon, ABS, PC, and PETG are a few of the filaments that are more hygroscopic.

PLA is one example of a 3D printing filament that is less hygroscopic.

You should dry out these filaments before you begin a new print.

How Do You Know If Your Filament Requires Drying?

You can tell if your filament requires drying through several different methods. One of them is to first heat the nozzle to the right temperature depending on the exact filament. After that, extrude 100 millimeters of filament.

In the event that you can hear sizzling sounds or small pops during the extrusion process, then you need to dry your filament. You can also tell you need to dry your filament if you see some steam coming out near the nozzle during the extrusion process. The water in the filament becomes water vapor when you are extruding and this can lead to issues when you start printing.

You’ll See More Obvious Stringing

Stringing is often the first indication that you have to dry your filament. You might even be able to get good prints with a certain filament brand for a while, but then stringing becomes a major issue after several months. You should be able to reduce or resolve the stringing issues once you have dried the filament.

Of course, this depends on the retraction. If you calibrate the retraction properly, then you have a better chance of resolving the stringing issues. This means you can get quality prints once again.

Another Sign of Your Filament Requiring Drying is Inconsistent Extrusion

One more way that you can find out that your filament has absorbed some amount of moisture is inconsistent extrusion. You will also notice that not all of the layers are aligned correctly, either. When your filament absorbs moisture, it typically does not absorb this moisture evenly.

This means that some portions of your filament will include more moisture than other parts of it. Extrusion causes this water to be released and therefore the nozzle’s interior pressure increases somewhat. This increase in pressure makes the machine extrude more plastic than necessary for a little bit.

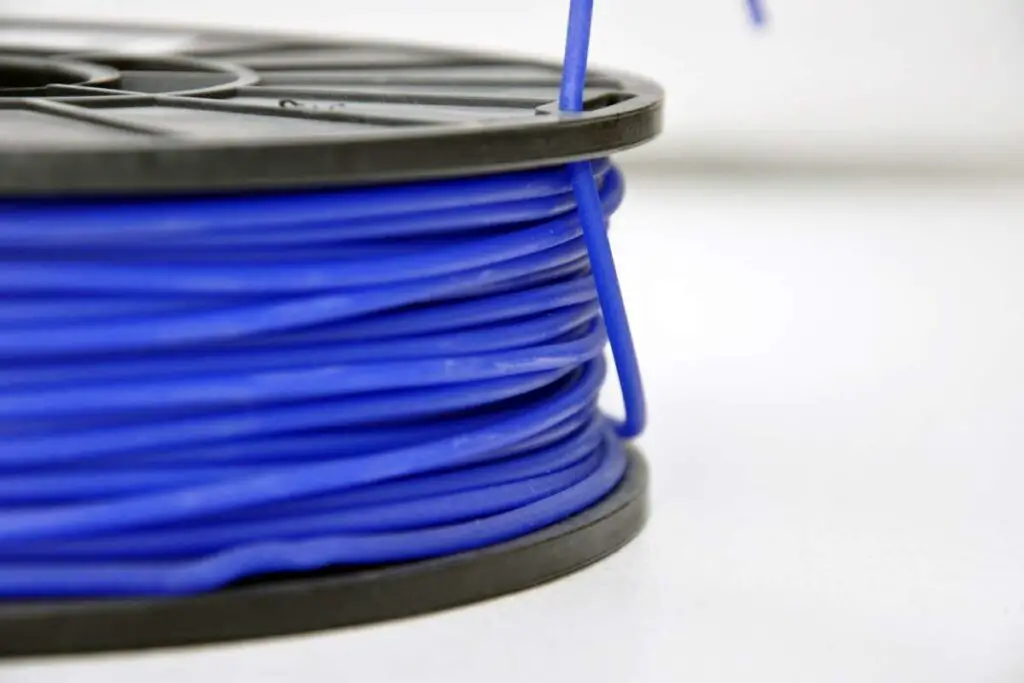

As a result, your filament’s layer lines become inconsistent and the prints are of lower quality than they would be otherwise. This is not all, though. Filament also tends to swell when it absorbs moisture.

Your filament could be a little bigger in diameter in some areas because of this swelling. It could be 0.8 millimeters in diameter when the regular diameter is a bit smaller at 0.75 millimeters. This causes low-quality extrusion.

You Could Get Brittle Filament That Breaks Easily

Brittleness and filament breaks are two more common signs of moisture absorption when using PLA filaments. This is due to the fact that the PLA filament becomes less flexible when it absorbs moisture. Of course, it is possible that you could notice this with other types of filament, as well.

Drying the filament should help quite a bit with this problem. Your filament should regain a bit of its prior flexibility. It should also prove more difficult to snap your filament once you have dried it out, as well.

What Do You Need to Dry Filament Properly?

In order to properly dry the filament, you need the right equipment.

In this case, that means that you require a machine capable of heating up the filament in a controlled fashion while also insulating the filament, too. One machine that you can use to dry filament is an oven.

You Can Dry Filament With an Oven

Putting your filament in the oven is the most efficient and simplest method of drying it.

However, not all ovens are suitable for this task. You have to use an oven that lets you accurately control its temperature. You should check to make sure that the oven’s thermostat is actually accurate before putting your filament in it.

The best way to do this is to use a regular thermostat.

Get a regular thermostat and put it into the oven after the oven has been preheated. That way, you can easily check the internal temperature of the oven.

You should ensure that the oven’s internal temperature is the same temperature that you set. If not, you should adjust the temperature accordingly. This is part of drying filament properly.

You can use any regular thermostat that works, but an infrared thermostat is one idea you might want to consider. There is often a small difference between the set temperature and the oven’s actual internal temperature.

For example, setting the oven’s temperature to 50 degrees Celsius and seeing that its actual temperature is 45 degrees Celsius is fairly common.

You have to adjust accordingly in such a case. Unfortunately, some ovens do not give you a very accurate temperature at all. When you are drying filament, but especially PLA filament, an oven overheating it can destroy it.

This is true even if the oven only overheats the filament for several minutes. Of course, you have other options for drying your filament.

You Can Dry Filament Using a Food Dehydrator

A food dehydrator is a common option for anyone who wants to dry filament. You can find many guides online about turning a food dehydrator into a machine for drying filament. However, this method does have its downsides.

The primary downside of using a food dehydrator is its maximum capacity.

You can only dry a single spool or perhaps two spools of filament at the same time, depending on the food dehydrator’s size.

Despite this, it is relatively easy to find an affordable food dehydrator.

You can get one on eBay if you wish. You can even buy a used food dehydrator if you want. After all, you are only utilizing the food dehydrator to dry the filament, so it doesn’t have to be new.

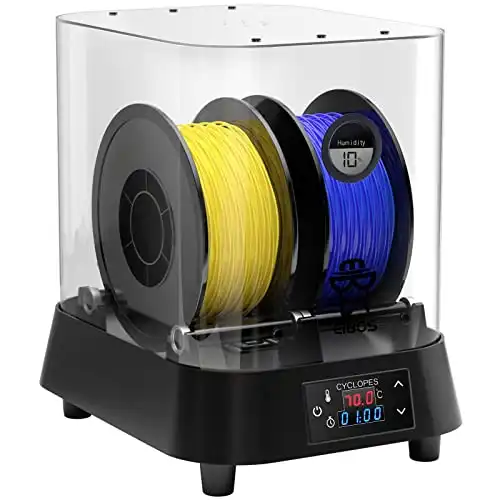

You Can Utilize a Filament Dryer

If you’re willing to spend a bit more money, then you can invest in a filament dryer. The main disadvantage to this is its cost, as you probably gathered. Filament dryers are not particularly cheap, so that is certainly something to keep in mind.

With adjustable temp, humidity monitor and multiple spool compatibility.

Filament dryers can only dry one spool of filament at a time.

However, if you print with PETG or Nylon frequently, you might want to get a filament dryer.

You can feed the filament directly from the filament dryer to the printer.

How Do You Dry PLA Filament?

PLA, also known as polylactic acid, is the most popular type of filament when it comes to 3D printing.

The first main reason for this is that you don’t need special preparations for PLA filament. The second main reason is that it is rather easy to print.

You should dry PLA filament at between 40 and 50 degrees Celsius.

You should maintain this temperature for a minimum of four hours if you are drying the filament using a ventilated oven.

How Do You Dry PETG Filament?

PETG is an alternative to ABS filament that is popular at the moment. It provides you with an easy printing experience and higher temperature resistance, too.

You should dry the PETG filament at between 60 and 65 degrees Celsius for a minimum of four hours.

How Do You Dry ABS Filament?

Many people still use ABS filament because it provides them with a good amount of temperature resistance.

It does have some disadvantages, though.

You should dry any ABS filament you use at between 80 and 85 degrees Celsius for four hours at least.

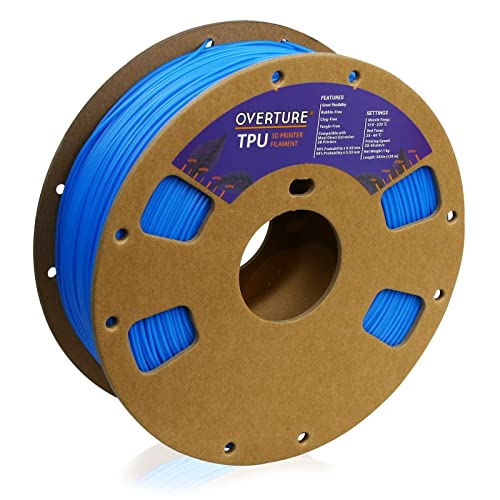

What About Drying TPU Filament?

TPU is not the most popular filament in general, but it is very popular among RC enthusiasts. This is because TPU filament gives you the ability to print models that are semi-flexible. Proper drying can really improve the quality of prints that use TPU filament. Dry your TPU filament at 40-45 degrees Celsius for a minimum of five hours.

What Is The Right Temperature For Drying Nylon Filament?

Nylon is a very hygroscopic material that you can use in 3D printing.

It is best to dry your spool before every single print because the filament will begin absorbing moisture as soon as you remove it from the bag.

You can dry Nylon filament in a few different ways.

One way to dry the Nylon filament is to build what is known as a filament spool holder. This insulates your Nylon filament during printing.

Otherwise, you can simply buy a filament dryer and use that instead. It is really up to you.

What Is The Proper Method of Drying ASA Filament?

When drying filament of this sort, you should know that ASA filament is great for printing 3D parts that will spend a lot of time outside.

ASA shares some similarities with ABS, but it offers you better UV resistance.

You should dry the ASA filament at between 80 and 85 degrees Celsius for a minimum period of four hours.