If you would like to have the surface of your laser engraved wood smooth, there are fine products for sealing wood that you can use. The most important thing is to know how to seal laser engraved wood.

Doing it the right way and using the right sealer will give you good results and make the surface of your wood eye-catching.

Here, you will learn all that you need on how to seal and finish laser engraved wood.

The Sealing Process

Step 1: Choosing your sealer and finish

The first step to a quality sealing process is choosing your sealer.

Remember, not every product will be good for the wood you are sealing. So, it’s imperative for you to find the right sealer to finish your laser engraving.

Step 2: Make sure that your laser engraved wood is clean

After finding the right sealer for the job, the next step is to make sure that the surface of your wood is clean.

Because a laser cutter can leave a lot of residue and dust, it is critical to remove any dust and any other dirt that might be on the surface using a clean piece of cloth.

This should be enough to prepare it for sealing.

Step 3: Apply the sealer

You can now apply the sealer to the wood. Take note that you should apply the sealer using a clean brush.

As you apply, make sure that you are doing it evenly along the wood’s grain.

Make sure that you cover the whole surface of the laser engraved wood.

Step 4: Allow the sealer to dry

After applying the sealer, you should allow it to dry completely.

Give it one to two hours to dry, depending on the type of sealer you are using.

You can check the instructions on your sealer to know the exact amount of time that you should allow it to dry.

Best Products to Seal Laser Engraved Wood

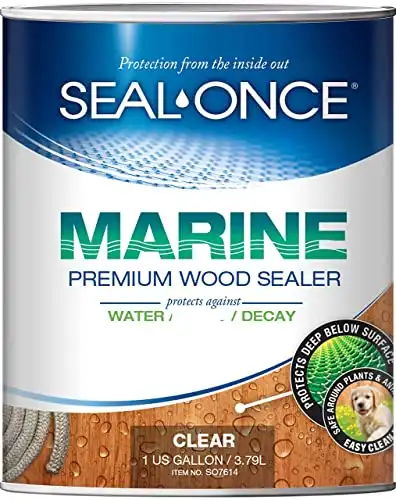

SEAL-ONCE MARINE Penetrating Wood Sealer

This sealer is known for its ability to penetrate the wood and build a flexible barrier.

It is resistant to mold, algae, and rot. It’s easy to clean because it’s water-based.

It’s also worth noting that it’s not toxic.

Ready Seal 512 Wood Sealer

The advantage with this sealer is that it gives the wood a lush finish.

It has eight different shades. If you want a specific shade, you can choose from the available ones.

Plus, if you choose to use this sealer, you won’t have to worry about streaks forming.

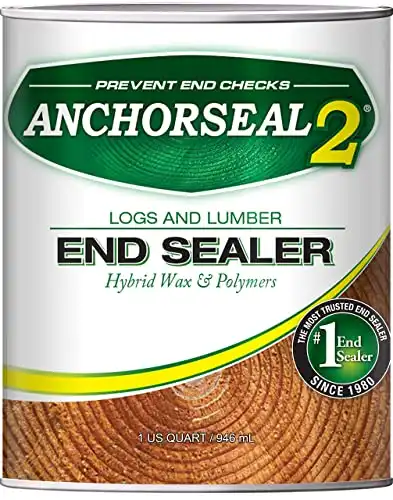

ANCHORSEAL 2 Green Wood Sealer

This product is water-based and non-toxic.

It dries clear, which is a plus for your project. Another advantage is that it is affordable. With this sealer, you are able to get a fine result for your laser engraved wood.

100% Pure Tung Oil Finish Wood Sealer

It produces a fine and rich finish for your wood surface. It is known to create a moisture-resistant barrier that protects wood from liquids such as water, oil, and acid.

The only thing you need to be aware of is that it is time-intensive when applying it on wood.

Tips and Tricks

One of the tips and tricks that you should know is that when you are applying a finish on laser engraved wood, you should take note of the end grains.

Make sure that the end grains are properly sealed. If you fail to seal them properly, they will absorb stains and finishes differently from the rest of the surfaces.

This will definitely affect the results of your process.

Moreover, after the sealer has dried completely, you can sand the surface.

Make sure that the sanding is light. Fine-grit sandpaper will do just fine.

Remember, the sanding should not go through the sealer. You can now remove the sanding remains with a piece of cloth.

Finishing Things Up

Laser engraved wood surfaces can stay smooth and lush for a long time, but you have to work on them to have such a result. This will require you to seal your wood surface properly.

Sealing a laser engraved wood surface is a viable option if you are expecting it to last.

The fundamental thing here is to have the right product for this work and then seal it following the right procedure.

There are plenty of options to choose from on how to seal laser engraved wood, so take your time to pick the one that meets your taste and preference.