What is Layer Height?

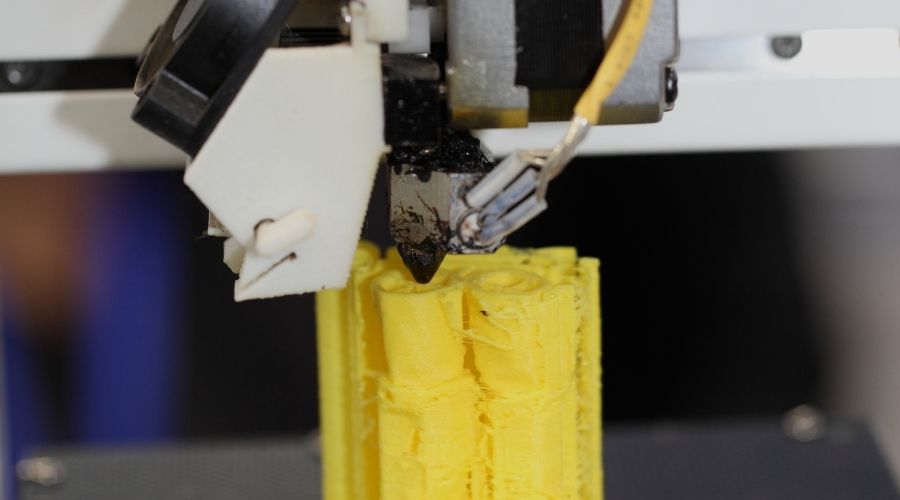

Layer height refers to the precise size of every layer of plastic cured, sintered, or extruded by a 3D printer.

The thinner your layer is, the more layers per millimeter you require, creating a smoother texture on the printed object.

Notably, the smaller layers generally have a longer print time compared to printing at larger heights.

You can adjust the height setting using slicing software, producing more detailed effects on the final prints to suit different needs. This adjustability enables you to improve your operating resolution, speed, and smoothness for high-quality results.

Layer Height settings in 3D printing use microns as a unit of measurement, with one micron equaling 0.001mm.

Manufacturers incorporate different maximum resolutions for layer height into various printers, enabling you to choose the ideal fit for your printing needs. Generally, the standard smallest height is between 0.05 and 0.1mm (50 and 100 microns).

Laser and resin-based printers provide a smaller minimum layer height than Fused Deposition Modeling (FDM) devices, enabling them to create detailed and precise prints.

In addition, FDM printers feature a unique design, where the taller vertical layer produces a thinner horizontal line. In contrast, a shorter vertical layer creates a thicker horizontal line, meaning you need to consider this function since it can throw off accuracy in the horizontal plane.

Why is Layer Height Important?

Layer Height in 3D printing is important because it helps you create various 3D objects with different levels of precision and intricacy. This flexibility makes it a suitable printing technique for users with several 3D printing requirements, influencing the printing cost, time, physical properties, and visual appearance.

The following are different and essential advantages of focusing on the layer height utility on your printer:

Control Surface Quality

Surface quality is proportional to how small your layer height is, with lower application settings producing smoother finishes.

However, models not requiring fine surface details let you utilize larger layer heights, reducing the print time without sacrificing quality or strength.

Offers Adjustable Time

Different layer heights influence the time taken to complete a 3D print. Therefore, you can modify your printing speeds by adjusting the layer height applied according to your needs.

For instance, you can use thinner layers at slower speeds to create a steady base for the initial layer.

After this, you can switch to higher layer heights when working on sections of less visual significance, helping you enjoy efficient printing times.

Enhances Intricate Details

The thinner the layer, the more detailed finish you create with a smoother finish. Furthermore, you can adjust the operation settings, such as exposure duration, to utilize the optimal settings for accurate and high-quality surface finishes.

Enables Professional and Leisure Applications

This printing technique is essential since it enables experts and first-time users to create quality 3D models. You can depend on it to deliver professional-quality results or use it as a hobby to produce figurines or miniatures for your leisure. This versatility makes it suitable for different users, allowing you to develop and grow your 3D printing skills over time.

Layer Height in SLA Processes

Layer height is critical in SLA printing since it determines your cost, model’s visual appearance, and duration. For example, you will hardly distinguish two models visually when you create two objects, one with 200-mm and another with 100-mm layer height. Nonetheless, the printer takes twice as long to complete the 100-mm thick object since it needs to print double as many layers.

SLA’s application of layer height printing makes it perfect for projects and rapid prototyping tasks needing outcomes with finely detailed and precise parts.