The History of 3D Printers

This history of 3D printers is nothing short of a scientific breakthrough. 3D Printing technology was one of the greatest technological advances in the last 50 years and has completely changed how we view what is possible in many scientific fields.

1981-1999:

The history of 3D printers started way back in the year of 1981 when Hideo Kodama shared his discovery of a rapid-prototyping system with the help of photopolymers. This account was published from the Nagoya Municipal Industrial Research Institute, where printed models were built through layers that correspond with cross-sectional models.

After three years, in 1984, 3D printing was created through the invention of stereolithography by Charles Hull. This allows designers to make 3D models from the tangible objects that were created with the help of digital data.

In 1986, Hull started his company called the “3D Systems” located in Valencia, California. Upon this year, Hull and his team have also started with the commercialization of the rapid prototyping. Hull then realized that his invention can also be used in a wide variety of forms, aside from liquid. As a result, he named 3D printing as “stereolithography” and filed a patent claim for it.

In 1992, Hull’s 3D Systems company created the first ever stereolithographic apparatus (SLA) on The Arsenio Hall Show. The SLA machine was designed to fabricate each layer of the parts. In the same year, a machine called selective laser sintering (SLS) was designed to shoot powdered lasers. All these technologies were still in their infancy and various developments are yet to be done.

1999-2010:

In 1999, the first ever 3D organ was printed at the Wake Forest Institute for Regenerative Medicine. The scientists have printed a human bladder in a synthetic form, and had them coated with human cells. Patients were then implanted with these generated tissues, with the assurance that their immune system will accept them since they are made with the patient’s own cells.

3D printing has made a massive impact on the medical field. In just a span of 10 years, scientists all around the world have incorporated 3D printing to help patients who are suffering from kidney dysfunction, blood vessel complications, leg injury, etc. through the help of human cells.

In 2005, Dr. Adrian Bowyer launched a RepRap Project, where he created a self-built 3D printer that has the ability to print out its own components. In 2008, Darwin launched a printer that can replicate itself. Since then, countless 3D printing machines and projects have been made.

Eventually, in the year 2006, the SLS machine was commercially available, and this resulted to a booming demand for industrial parts manufacturing. A 3D printing machine that is capable of print in multiple and various materials was also made during this year by the startup company called Objet, which has now merged along with Stratasys.

2011-Present Times

Through the constant and ever rising development of technology, various innovators are coming up with cheaper and better 3D printing machines in the market. Today, 3D printings are no longer limited with plastics, but can also be used with gold or silver. 3D printing is incorporated among various industries such as aircraft, jewelry, medical, dentistry, housing, as well as the manufacturing of different items that we see in our day-to-day lives.

Who Created the 3D Printer?

In 1984, Charles “Chuck” Hull invented the first ever 3D imaging process printer in the field of stereo-lithography. Hull, who invented the first 3D printing technology is considered a technological pioneer. Hull had first thought of the idea one year prior to the invention, while using UV light in hopes to harden the coatings of a tabletop.

Charles “Chuck” W. Hull was born on May 12, 1939 in Colorado. He spent his early days in Gateway and Clifton Colorado with his parents Lester and Esther Hull. He graduated high school from Central High School and took Bachelor of Science in Engineering Physics in the University of Colorado in 1961.

Because of his invention of the first 3D printing machine, Hull was named not just in U.S. patents, but in patents all around the globe within the fields of rapid prototyping and ion optics. In 2014, he was also included in the National Inventors Hall of Fame, as well as in the 2017 TCT Hall of Fame. And not to mention, in 2011, it was revealed that his salary from his 3D System company amounts to $307,500.

Hull was awarded with the European Inventor Award in 2014, given by the European Patent Office. Furthermore, his stereo-lithography invention was awarded with the IRI Achievement Award by the Industrial Research Institute in 2015. Up to this day, Charles remains as one of the most notable inventors that shaped the operation of many industries today.

When was the First 3D Printer Made?

The idea first came into Hull in the year 1983, one year prior to the launch of the first ever 3D printing machine being made in 1984. The idea came up to him as he was hardening the coatings of a tabletop. Consequently, in July 16, 1984, Olivier de Witte, Jean Claude Andre and Alain Le Mehaute filed their own patent to aid the stereo-lithography procedure. This occurred three weeks prior to Hull’s stereo-lithography patent filing.

The CILAS (now The Laser Consortium) and French General Electric Company (Alcatel-Alsthom) have abandoned the applications that were made by these French inventors because these companies did not perceive their invention as a profitable product because according to them, it lacks business perspective.

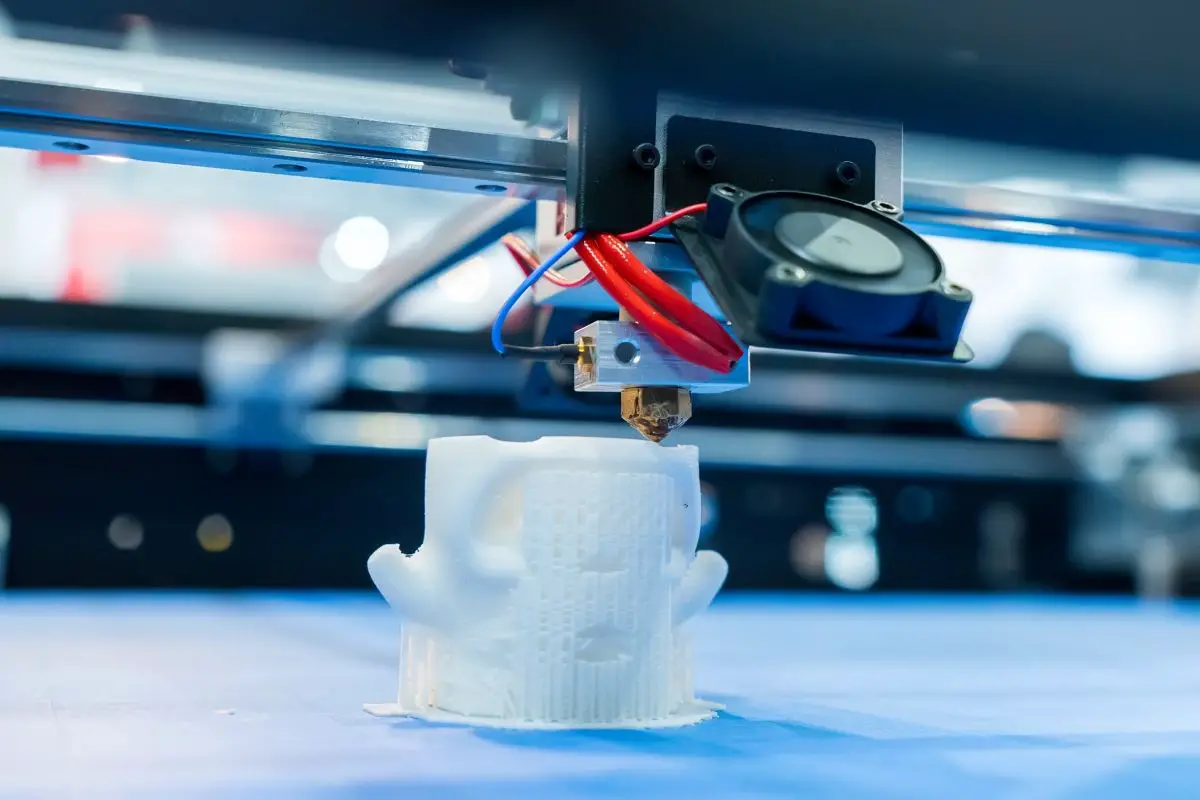

In Hull’s U.S. Patent called “Apparatus for Production of Three-Dimensional Objects by Stereo-lithography,” he invented the word stereo-lithography–which is defined as the apparatus and method of printing layers and layers of thin materials, in order to make a solid object. Hull used a concentrated ultraviolet light beam on the surface that is filled with photopolymer in its liquid form.

The ultraviolet light beam allows each layer of the material to be placed in the liquid photopolymer. The liquid cross links or polymerizes upon its contact with the light beam, and then it changes into a solid form. An advanced CAM/CAD/CAE software can slice various materials into thin layers, then rebuild the object from bottom to top, solidifying it layer by layer.

What is the Main Purpose of 3D Printing?

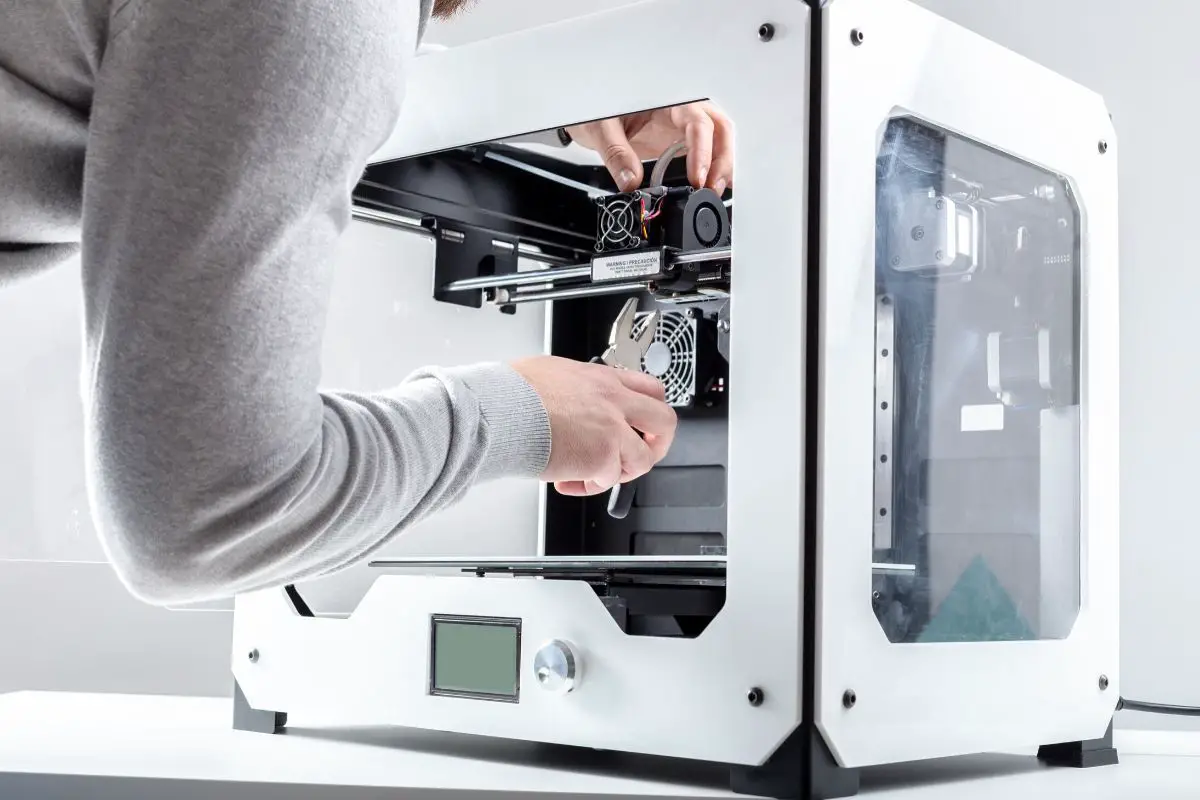

Back in the early days, 3D printing demanded expensive entry costs, which hinder the manufacturers to implement this in their businesses for the mass production of goods. But today, as technology improves, more and more innovators are coming up with various 3D printing machines that are way more affordable and advanced. As the days go by, 3D printing has shown a massive improvement and can now be used in a wide variety of industries such as medicine, manufacturing, architecture, design, and many more.

3D printers can be used for both personal or commercial uses. The main purpose of 3D printing is to create items by using a minimal amount of material to eliminate waste and material costs. Mass-manufacturers highly benefit through 3D printing technology since it allows them to produce huge amounts of goods in a cost-efficient way, without having to worry about material wastage.

What Industry Uses 3D Printing?

Medical Field

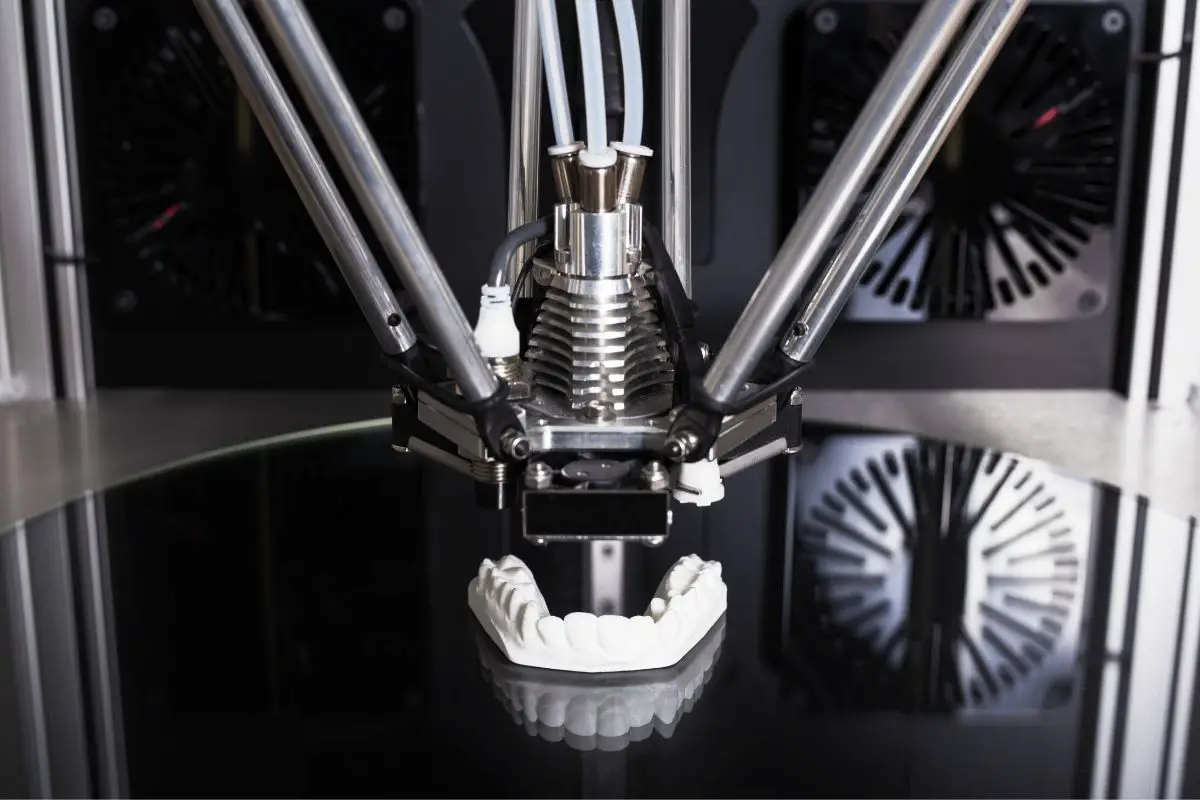

3D printing is widely used in the field of medicine especially during the mid-1990s. Surgeons use these technologies through a tactile model to prepare them for an upcoming surgery. Moreover, patients who are required to undergo craniomaxillofacial reconstruction or joint replacement can use a personalized instrument provided by 3D paintings.

More and more hospitals have incorporated the use of 3D printing within their specialty departments, in order to plan for a heart or organ surgery. This type of technology can also be used to create patient-matched and personalized devices for uncommon illnesses. An example of this would be the 3D printed patient-matched surgical guides made by the University of Michigan to treat newborn babies with tracheobronchomalacia. 3D printing can also be used to replicate organs. Surgeons can use the CT scan or MRI images as a basis in order to make an exact replica of their patient’s organs.

Manufacturing Industry

Among all the industries, 3D printings are most prevalent in the manufacturing industry. The expansion and development of these types of technology has brought massive improvement in data visualization, product development, specialized manufacturing and rapid prototyping.

Manufacturing companies incorporate 3D printing in order to allow their customers to personalize objects. An example of this would be custom made cell phone cases. Furthermore, 3D printing allows rapid manufacturing with a relatively inexpensive cost.

Industrial Uses

3D printing is used by apparel designers to experiment with their dresses, swimwear and shoes. As a matter of fact, in 2012, Nike incorporated 3D printing to manufacture their Vapor Laser Talon shoe for football players. Moreover, 3D printing can also be used by optics to make a custom fit eyewear through rapid prototyping.

3D printing technology is also widely utilized in the automotive industry, as it helps them with the manufacturing process by printing various components such as air ducts, side mirrors, turbocharger assemblies and exhaust components.

The construction and architecture industry also benefit from 3D printing as it enables them to increase the efficiency of their production and the materials that are being produced. The 3D printing technology is also widely used in the production of diverse items such as firearms, jewelry, computers, soft sensors, robots, and many more.

If you enjoyed this article, you may like The Best 3D Printer of 2020: Complete Reviews.