Users of the 3D printers received dozens of new printing opportunities with the introduction of dual extrusion 3D printers. However, if you plan to buy such a device, you should understand what are the principal differences between a 3D printer with single vs dual extrusion. After all, these devices are quite expensive machines, so you should make a well-informed decision.

Before getting into checking the differences, let’s learn more about the basics of 3D printing. First, 3D printers were quite simple machines that used only a single extruder. The user of such a device could use only one material at the time.

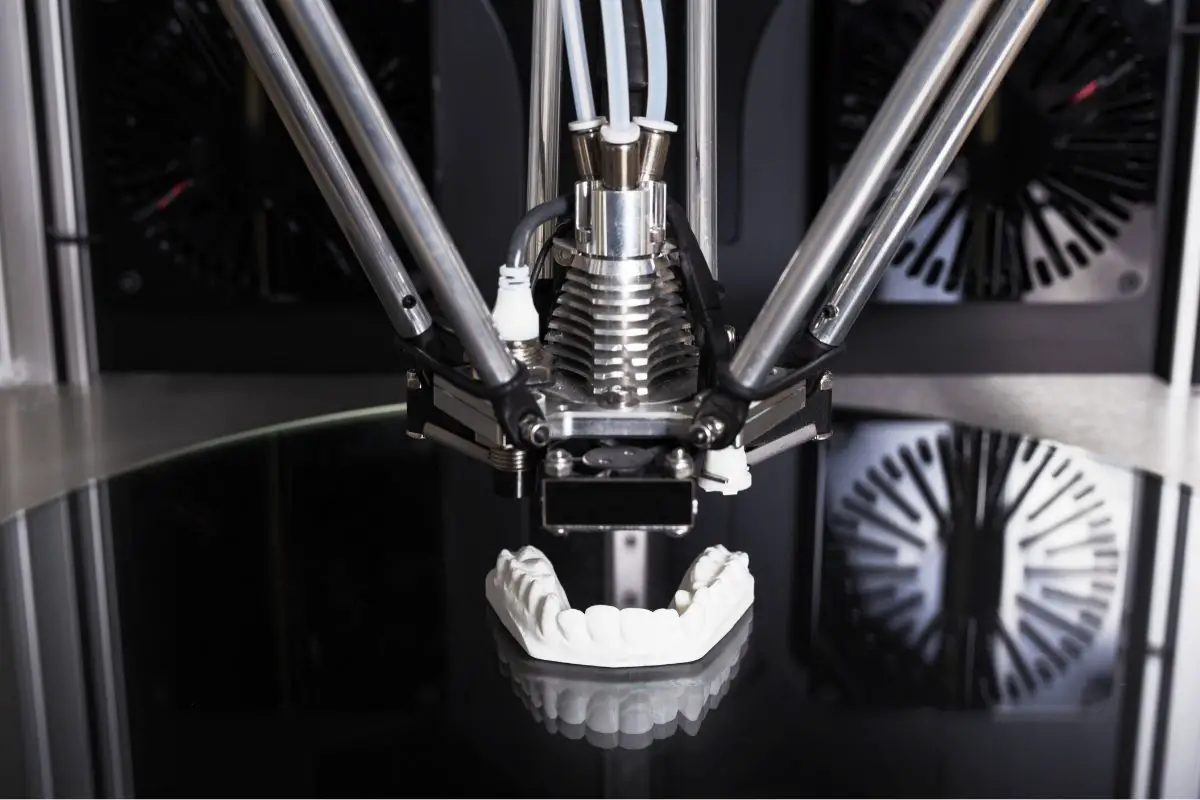

On the other hand, dual extruder 3D printers allow you to use two extruders and nozzles. So now, you can use two different materials to print the needed parts.

Single vs Dual Extrusion 3D Printers

Nevertheless, the printing process of both these models remains the same. The only difference is that a more advanced dual extrusion printer gives you an ability to switch between the filaments at any moment.

Giving you an ability to combine standard materials with other support ones, the dual extension increases the functionality of the printing process. Now you do not need to remove supports, and there will not be any support marks on your final print.

Another advantage of 3D printers with dual extrusion is the ability to reinforce one of the used materials with a stronger one. Also, you can use two different colors when printing. So having such a device, you can use PLA to print the biggest part of your print and use another nozzle to supply a carbon-fiber filament for reinforcement of your product. It will make it extra durable.

Of course, dual extrusion 3D printers also have some disadvantages.

The most obvious one is its price. Such devices are much more expensive than single extrusion ones.

Furthermore, you will have to buy additional filament, so it also adds to the costs of the final print.

Moreover, all 3D printers require some care. And the second extruder and nozzle double the number of potential failures and problems.

Pros and Cons

Now you know what the differences are between single vs dual extrusion 3D printers. So let’s summarize the pros and cons of dual extrusion devices.

Pros

Colors

If you need to print colorful details and elements, a dual extrusion printer has an advantage of printing in two colors, which is not possible with the single extrusion model. It also allows you to use different colors in particular places of your print. So, using such a printer, you can print automotive or anatomical educational models.

Supports

Dual extrusion 3D printer allows you to combine your standard material with a dissolvable one for support. It is the most significant advantage from a functional perspective, as there is no more need to remove supports. And support marks will not worsen the appearance of your final print. HIPS and PVA are the most common dissolvable filaments for support constructions. HIPS dissolves in limonene, while water is enough to dissolve PVA.

Structure

Also, as was mentioned above, dual extrusion 3D printers allow you to reinforce your print by using a stronger material. Using carbon-fiber filament with the PLA one makes specific areas of your print much stronger.

Cons

Dual extrusion 3D printers do not have many disadvantages. The only drawbacks are their price and maintenance. Such machines are more expensive than single extrusion devices, require more care and more filament.

Dual Color Printing with Your 3D Printer

If you already have a single extrusion 3D printer and buying a new dual extrusion device is too costly for you, there are some methods of multi-color printing.

But you will have to stop printing and change the filament. It requires a lot of effort, and the quality of the final product is not excellent. Also, you cannot reinforce it by using two different materials simultaneously.

3D Printer Single vs Dual Extrusion: Which is Better?

Dual extrusion 3D printers are more advanced than single extrusion ones, and they allow you to create more complicated prints. They have better functionality and provide you with more printing abilities.

However, dual extrusion machines are still quite expensive.

Also, they require more care and additional filaments.

Of course, they are better than single extrusion printers. But to use them properly, you should have some experience in 3D printing. And single extrusion devices are still the best option for beginners, who need to gain this experience.