When trying to figure out what technology to use for a 3D printing project, many people compare SLS vs. SLA printers.

SLS stands for selective laser sintering. An SLS printer works by melting or fusing together powdered material to form a design.

SLA stands for stereolithography. An SLA printer works by solidifying a design into several successive layers of resin. SLA printers are cheaper and better for small, intricate objects. SLS printers can work with a wide variety of materials, but they are very expensive.

SLA Printing

SLA printers work with the resin that is most commonly associated with home 3D printing. They use a laser to solidify layer after layer of this resin in order to create a pre-programmed design.

SLA printing is sometimes confused with DLP (digital light projection) printing, but it is quite different. DLP printing uses a projector screen to guide the creation of the object. However. SLA printers use a laser beam that is directed at various different points of the object in succession.

Printing Upside Down

A design in an SLA printer begins as a 2D pattern that is suspended upside down. A reservoir of resin is connected to the bottom of the pattern. The laser will then solidify layer after layer of resin until the process is completed.

SLA printing looks a little strange to people who are not experienced with this method. This is because the object is created while upside down, while most 3D printing processes create the object with the top side up.

UV Resin & UV Lasers

SLA printers use UV-curing resin. If you are using a resin printer with a hot end, you will have to cure UV resin after printing with a UV light. However, SLA printers cut out this step by using a UV laser to solidify the resin as part of the printing process.

Laser Precision

There are two different ways that an SLA printer adjusts its laser during the printing process. Most SLA printers use several mirrors that reflect the laser onto the area of resin that needs to be solidified. However, some SLA printers move the laser itself with a device called a gantry. The SLA printers that use gantries are generally high-end models.

No matter which method the SLA printer uses for deploying its laser, it will be able to create objects much more precisely than the more common FDM printers. This is because the width of an SLA printer’s laser is considerably smaller than the nozzles used in FDM printers.

The Drawbacks of SLA Printing

While solidifying the resin as part of the printing process is convenient, it is not without its drawbacks. It is important that the printer either be covered or placed in a dark room. Otherwise, ambient UV light may cause the design to solidify improperly.

Also, the process of solidifying 3D resin with a laser often releases a toxic vapor. This vapor has an unpleasant odor, which serves as a warning to anyone nearby. If you use an SLA printer, you need to ensure that your printing room is well-ventilated.

SLS Printing

SLS, or selective layer sintering, is rarely seen amongst hobbyists or crafters due to the high costs of SLS printers. However, the fact that SLS printers can work with tough materials like metal and ceramics means that they are very common in industrial 3D printing operations.

SLS printers can work with such tough materials because the material used in this printing method starts out as a powder. An SLS printer cannot build a 3D design out of a solid block of metal or ceramic material.

The Material

The SLS printing process starts with the selection of the material. While SLS printers are known for working with advanced metals and ceramics, they can also work with various thermoplastics, such as nylon. They do not use the resin that most 3D printers use.

As mentioned, SLS printing material starts out as a powder. All materials, whether they are plastics, metals, or ceramics, must be powdered specifically for use in an SLS printer.

It should be noted that while SLS printers can certainly create solid bonds between layers of plastic, they cannot create a truly solid bond between layers of metal or ceramic. This is true of even the most powerful SLS printers on the market.

Metal or ceramic designs created by an SLS printer must be processed by a kiln or an oven to further strengthen the object. This is another reason that SLS printers are generally only found in industrial operations.

The Process

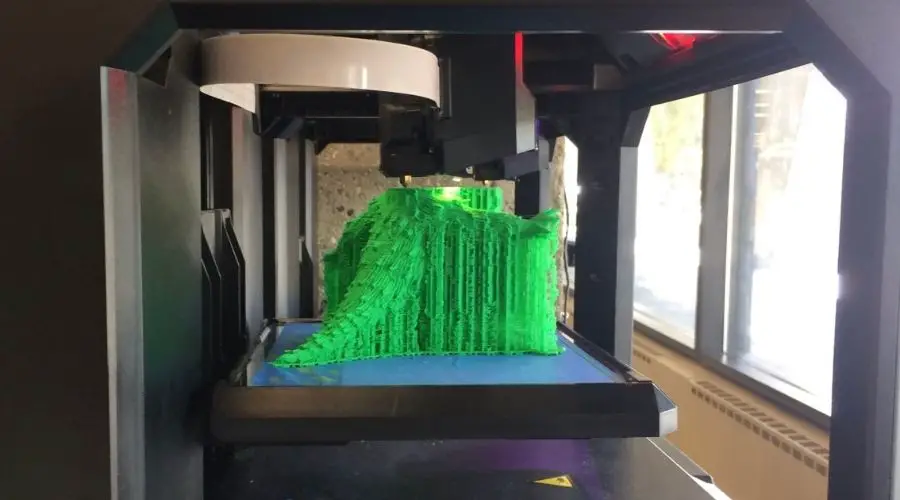

Unlike the SLA printing process, designs are not suspended upside down in an SLS printer. Instead, a roller deposits layers of powdered material as the laser melts the previous layer.

This means that each layer is only partially melted before the next layer is rolled on top of it. While the laser itself does most of the melting, the residual heat of the layer underneath will help melt the new layer, thus strengthening the bond.

While printing in an SLA printer requires the use of a mold, this is not the case with SLS printing. This is because the layers underneath the newest layer support each other. This means that objects created in an SLS printer can have a more complex internal structure. This is the second reason (in addition to the versatility of materials) that SLS printers are very popular in industrial operations.

Similarities In SLS vs. SLA 3D Printers

The only similarity in the technology of SLS printing and SLA printing is the use of a laser to shape the material. This may seem like a surface-level similarity, but it does lend itself to some common characteristics.

For example, designs printed by SLS printers and SLA printers are very precise. Both SLS and SLA printers are much more precise than FDM printers. Also, the use of a laser to shape the object means that hot ends are not necessary. Hot ends can cause a lot of problems in 3D printing.

They can jam or become clogged. The use of lasers in both SLA and SLS printing also eliminates the risk of prints becoming warped, which is always a risk when using an FDM printer.

Differences Between SLS & SLA Printers

Mirroring

The system of mirrors used in most SLA printers can distort the laser slightly, leading to reduced precision. SLA printers that use a gantry instead of mirrors do not have this problem.

The mirrors used in an SLS printer can also distort the laser slightly, but this problem is much less pronounced due to the high-tech systems used in these cutting-edge printers.

Materials

SLA printers use resin. This material is affordable and readily available. However, it is also messy and toxic.

SLS printers can use plastics (most commonly nylon thermoplastic), metals, and ceramics. The materials are expensive and must be in powdered form. However, they are not as messy. Toxic fumes may also be emitted during the process of SLS printing.

Size

SLA printers are generally small, light, and easily portable. This means that the majority of SLA printers can only print large designs by creating one part at a time. SLS printers are much larger and heavier. However, they can also create much larger designs all at once.

Applications

SLS and SLA printers are often used for very different applications. SLA printers can create parts that have very high levels of external detail. This makes them ideal for models, jewelry, and other items where appearance is the most important factor. However, the use of resin in these items makes them relatively weak.

SLS printers cannot create parts with as high a level of external detail. However, they can create parts with more intricate internal structures. Also, they can work with much stronger materials than resin. This makes SLS printers ideal for creating parts that need to understand strong forces. For example, many automotive manufacturers use SLS printing to create internal parts and protoypes for their vehicles.

Price

Price is the main reason that the vast majority of hobbyists and crafters go with SLA printers over SLS printers. You can find acceptable home-use quality SLA printers for less than $500, while SLS printers start at around $5,000 and go way up from there.

Which is better?

When you’re comparing SLS vs. SLA printers, you have to consider what you want the printer for.

If you want a 3D printer because creating 3D printed objects is a hobby, you should go with an SLA printer. It is much more affordable, and you will not need the added functionality of an SLS printer. If you are planning on running a business involving 3D printed objects, consider what these objects are used for.

If you are creating toys, models, jewelry, or similar objects, a high-end SLA printer is your best bet. If you are planning to create 3D printed objects that must withstand high temperatures, strong forces, or both, an SLS printer is right for you.