CNC (Computer Numerical Control) programming is growing in popularity in the manufacturing industry due to its many applications.

The ease of use provided by automated machine tools has made it easier than ever to manufacture parts for different uses.

CNC programming provides automation, cost savings, excellent machining quality, flexibility, reduced production time, and a host of other benefits to manufacturers. It is an incredibly versatile industrial solution that can be used with wood, metal, plastics, composites, glass, foam, and more.

This guide contains everything you need to know about CNC processes, including their history and the many ways you can apply them to boost your production process.

Let’s dive in!

History of CNC Programming

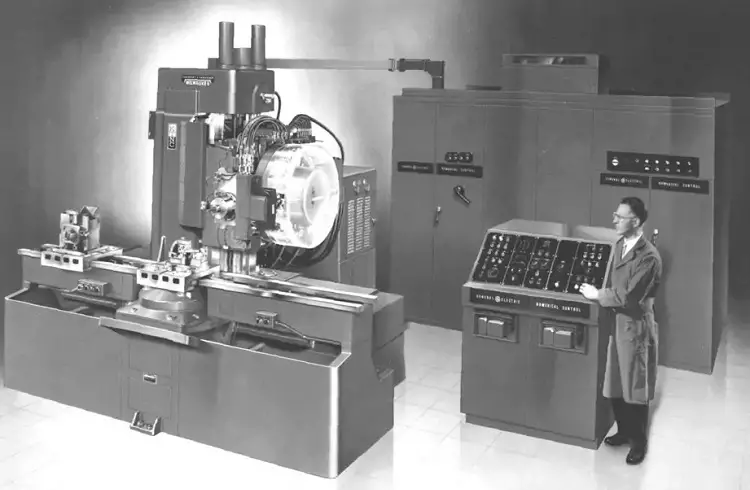

The first CNC programming concept was developed in 1949 by a computing pioneer named John T. Parsons. He was part of an Air Force research project at the Massachusetts Institute of Technology (MIT).

He built an experimental milling machine at MIT’s Servomechanisms Laboratory. He wanted to use axes to make aircraft parts such as helicopter blades and stiffer skins.

Before this MIT collaboration, Parsons Corporation in Michigan used an IBM 602A multiplier to calculate airfoil coordinates. They fed the data into a swiss jig borer by feeding punched cards into the system, and they successfully used preprogrammed information to manufacture helicopter parts.

In 1952, Richard Kegg launched the Cincinnati Hydro-Tel in collaboration with MIT. It was a 28-inch vertical-spindle contour milling machine.

CNC machines in the 1940s and 1950s used punched tape. The 1960s and 1970s saw the emergence of digital computing technologies, which automated the manufacturing process and made it more efficient.

The advanced automated motion control systems used by today’s manufacturers are based on their predecessors’ main components: a command function to activate it, a drive or motion system like a cylinder, motor, clutch, or valve, and a system to provide feedback.

Types of CNC Processes

CNC programming encompasses various machining processes that you can use for your business.

Here are the different types of CNC processes you need to know about:

CNC Routing

CNC routers are used for cutting, milling, drilling, and so on. They are employed by manufacturers as a substitute for the commonly used hand-held router. They are mainly used to cut, carve, and engrave objects out of a workpiece.

CNC routing is perfect for businesses that need to make precise cuts at high speed. It significantly reduces production time, costs, and errors by introducing computer control to the machining process.

CNC routers can work with wood, metal, stone, glass, plastics, acrylic, and foam.

Plasma Cutting

Plasma cutting machines employ a thermal cutting method that uses an accelerated stream of hot plasma to cut electrically conductive materials.

A jet of ionized gas is ejected from an air-cooled nozzle at high speed. At the same time, an electric arc is generated onto the surface, and some of it is converted into hot plasma. The plasma melts the material and blows away molten particles.

These high-powered plasma torches can cut through stainless steel, aluminum, nickel, titanium, and other metals.

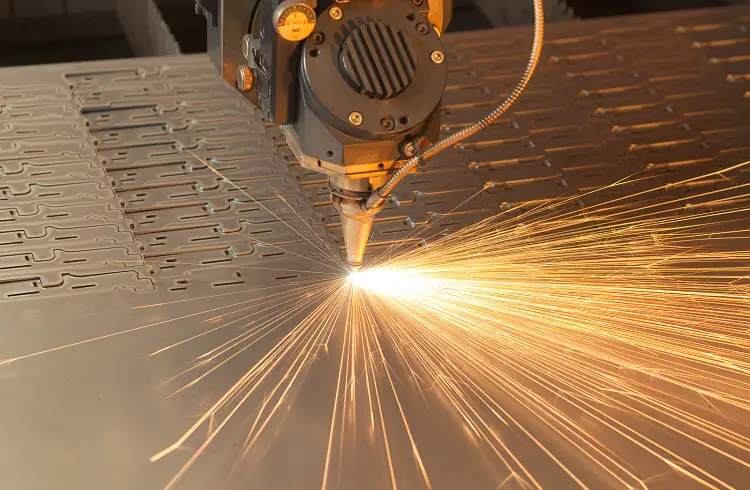

Laser Cutting

Laser cutting is a non-contact, thermal process in which a laser beam is used to melt and cut hard materials. A gas jet removes the molten particles while the material is cut by moving the beam or workpiece using computer controls.

There are three laser types: carbon dioxide, neodymium, or yttrium-aluminum-garnet. They can create complex, intricate objects out of plastics, paper, glass, wood, and metal.

Laser cutters are popular in fields like woodworking and automotive parts manufacturing. As laser cutters provide a high level of precision, cut quality, and flexibility, they are increasingly overtaking other types of cutters.

Milling

CNC milling relies on multi-point rotating cutting tools to eject material from a workpiece. It usually has built-in tools for drilling and cutting.

Milling machines feed the workpiece to the cutting tool in the same direction as its rotation. The programmed drilling commands are then implemented.

CNC milling machines are oriented vertically or horizontally. Many machines also come with three-axis or six-axis configurations. These multi-axis milling machines are used to manufacture gears or create deep cavities such as slots in a workpiece.

The machines are used for high precision mass production of parts for assembly.

Related: CNC Router vs Mill: What’s the difference?

Drilling

CNC drilling involves a rotating cutting tool with multi-point drill bits to create cylindrical holes in a workpiece. The holes are usually created for machine screws or bolts for assembling parts.

The CNC machine feeds the drill bit at 90 degrees to the plane of the stationary workpiece’s surface. This creates vertically aligned holes equal to the diameter of the drill bit used.

Note that angular drilling can also be done by using specialized machine configurations and work-holding equipment.

Toolpaths Used in CNC Programming

A toolpath is a sequence of coordinate locations that guides the cutting tools in a CNC machining process. Understanding the different toolpaths will help you improve production efficiency, even for complex projects.

Toolpaths provide greater control to CNC programmers to create complicated parts with ease.

Here are a few toolpath types that you can use to optimize CNC programming functions:

- Face: It removes loose material from a surface to achieve a superior finish.

- Pencil: It is specifically designed to clean up the internal corners and fillets on 3D projects by creating a single trace corner toolpath.

- Pencil Milling: This is a cleanup toolpath used to machine the corners and concave areas to achieve an optimum surface finish ready for polishing.

- Fillet: This employs a corner rounding tool to create fillets.

- Contour: It helps machine loops, stick fonts, open pockets, saw cuts, dovetails, and keysets.

- Pocket: It is used for roughing or finishing pockets of different sizes and shapes.

- Constant Stepover: It provides a consistently smooth finish.

- Rest Roughing: It helps achieve the required roughing by using large and small cutters.

- Chamfer: This is used for deburring and creating chamfers with the help of a center drill or tapered mill.

- Zig-zag Clearing: This bi-direction toolpath removes material through the cutter’s forward and backward movement. It optimizes the straight-line motion of a tool.

- Advanced Z Level Finishing: It is a 3D finishing toolpath strategy designed to machine vertical surfaces that need a consistent cut depth.

- Spiral: This helps create round machine parts with greater efficiency.

- 3D Plunge Roughing: It is used to drill large amounts of material for plunging movement.

- Slot Mill: This toolpath can be chosen to machine arc slots or straight slots.

Is CNC Programming Hard?

Basic CNC programming is simple enough for novices to learn. However, you need to have a basic knowledge of math, computer, and technical drawing. You also need to understand how manual machining works.

Many people master the basics of CNC programming, such as G-code and 2D-CAM programs, within a few days or a week.

If you wish to acquire intermediate skills, you can learn them within a year. Learning advanced and professional-level CNC programming can take many years. It includes topics like three-axis and five-axis CAD-CAM programming.

How Can I Learn CNC Programming?

CNC programming skills are much sought after nowadays. You should be able to find top-notch online courses that will teach you the basics and even transition into an advanced programming level.

But the best way to go about learning it is to first study manual programming. You will learn about various programs and codes and what you have to watch for so that you don’t feed wrong programs to the CNC machine.

Once you’ve mastered manual programming, you can study up on CAM systems. Fortunately, once you pick up one CAM system, learning another one should be much easier. You’ll be able to master the core concepts in no time!

Difference Between a CNC Machinist and a CNC Programmer

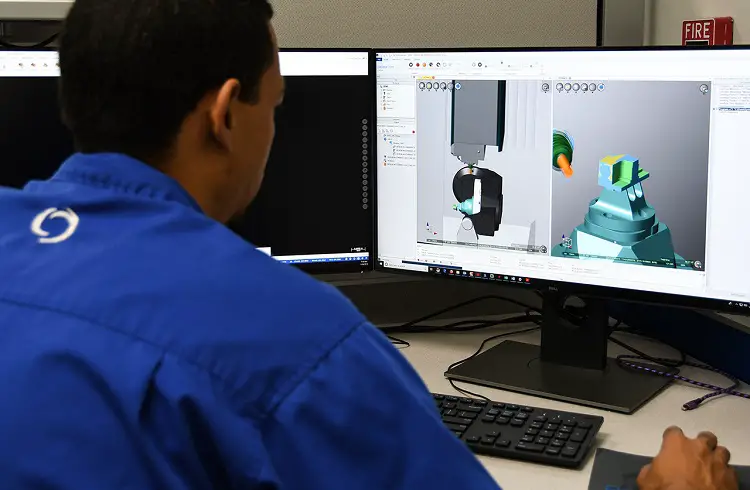

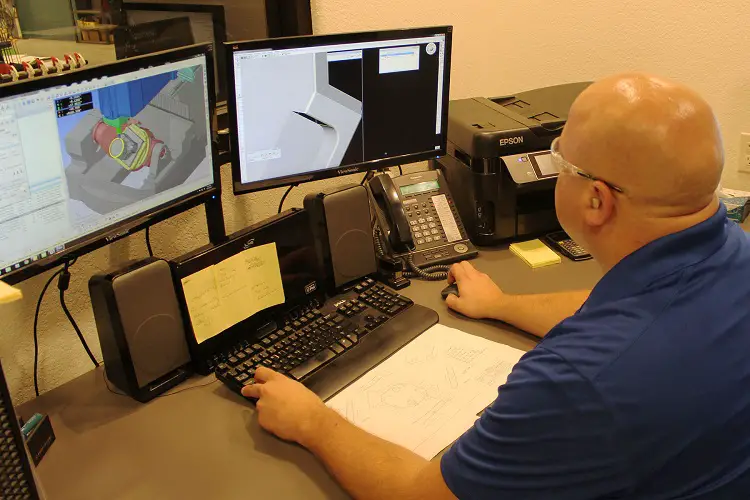

CNC programmers are in charge of creating codes and programs for CNC machines. They put together all the instructions required to run the machine.

CNC programmers read blueprints and 3D models to design and develop CNC programs. They must also calculate the amount of material needed, the speed at which it will be fed into the CNC machine for cutting, the placement or positioning of specific patterns or designs, and so on.

They convert all of this information into a series of instructions for the machine and machinist to follow. Their knowledge is much more specialized compared to CNC operators and machinists.

In contrast, CNC machinists take care of the manual operation and maintenance of CNC machines. In some manufacturing businesses, they may also be responsible for programming and setting up the machines for daily use.

Conclusion

We’ve shared everything you need to know about CNC programming. We hope this information we shared will help you use this powerful solution for your business and reap its many benefits.