Unfortunately, there isn’t an exact depth you can cut that is universal for all CNC Routers.

There are many variables that go into determining how deep you can cut.

If you are like me and want to get the most out of your CNC machine, then you will want to figure out the maximum depth of cut your router can make without issue.

Let’s dive right into some of the factors that help determine the possibilities of your CNC Router.

Machine Size

The size of your machine will play a huge role in what you can – or cannot – do with your CNC Router.

Let’s start with your Z-Axis height and how much clearance you have.

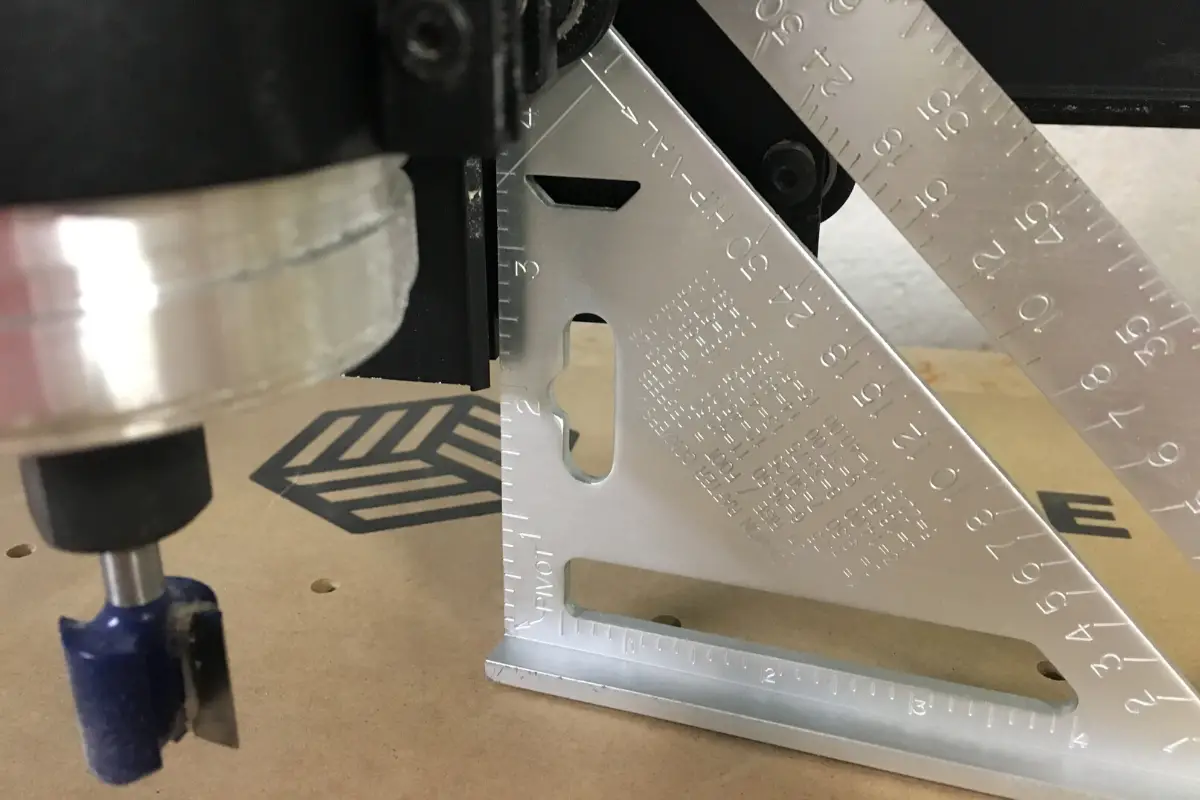

Measure from the bottom of your spindle carriage to the top of your waste board or t-track table.

Make sure your spindle is raised all the way up in your Z-Axis controls or out of the way to get the best possible result.

The measurement you get from this will unfortunately not be your maximum cutting capabilities.

This measurement is what we refer to as clearance. This will be the max height machine clearance for any work piece or clamps you may have on the table.

Always double-check the height of all items on the table before ever running your machine.

For holding down large work pieces, we highly recommend using double-sided tape. A lot of hobby CNC machinists will upgrade their gantry’s to increase their overall z-axis height, thus opening up a world of possibilities with their router.

Tool Length

The length of the tool you are using will play another big part into determining how deep you can cut with your CNC Router.

You will be able to figure this out by measuring your bits flute length.

To measure this you will start at the end of the flutes and measure up to where the flute meets the shank.

The most common CNC Router bits you’ll see are 2 1/2″ overall length and with a 1/4″ in diameter.

These will most likely not enough to cut the maximum depth on your machine.

You don’t want your tool sticking out too far due to flexing, especially with only a little bit of your tool shank in the collet.

We recommend a tool length of at least 3″ and a flute length at least the height of your work piece.

Machine Rigidity

The overall rigidity of your machine will play a major role in not only how deep you can cut, but with what materials you can cut.

The typical aluminum DIY CNC Routers such as the X-Carve will leave a lot to be desired when it comes to rigidness, so make sure before you start machining, you have the best possible feeds, speeds, and set-up.

Double-check your program and settings as well because you don’t want to be 2 hours into a program and realized you made a mistake. Always remember when you have an extended tool length there will be some flexing when making deep cuts.

We recommend for cuts that are pushing the limits of your router, to always play it safe.

That means slowing your feed rates and taking small depths of passes.

Your tool will be under immense pressure when cutting all the way through material due to the fact that it will be making contact radially in most cases.

Make sure to remove any excess chips and dust while making those passes.

Too much dust and chips will increase the likely hood of tool wear and tool breakage.

Recap

Let’s do a quick recap of all the factors that go into how deep you can cut with your CNC Router.

Machine size and gantry height are some of the most important measurements needed before determining cutting capabilities.

The length of your tool, including the flute length, is also very critical.

Next, there is the rigidity of your machine, and we suggest adding stiffeners to your rails for better success.

Use these tips to get the most of your machine and never stop improving!

- Machine Size (Z-Axis Clearance)

- Tool Length (Overall and flute length)

- Rigidity of Machine (Aluminum extrusions are known to flex)

Let us know what projects you guys are working on!

Sign up for our newsletter for great project ideas and tutorials on making money with your CNC Router.