Before getting started with your 3D Printing journey it is important to what you are getting into and how much things will cost down the line. Like how much filament do I need for 3D printing and what 3D printer should I buy? Knowing this, as well as all the other information provided down below, will help you save money but also, give you a better idea of what type of printer you need.

For starters, not every 3D printer is used the same. Some people only use it as a hobby, some only use it for beginner/easy projects, and you even have those people that like to use their printer for super-advanced/complex projects such as 3D printing a house or a car.

Knowing which of the categories of people you fall into will help you figure out how much filament is needed for your project.

How Much Filament Do I Need for 3D Printing?

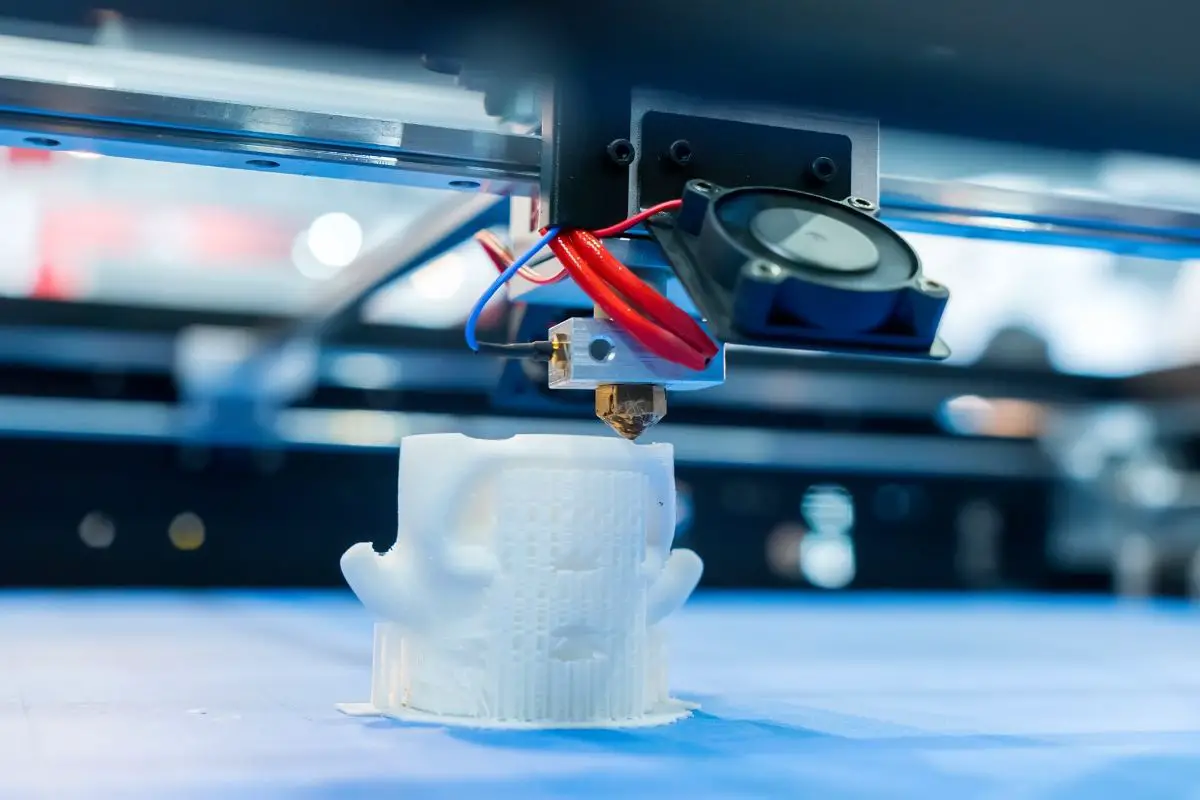

Luckily, it’s pretty simple to find this out. All you need to do is load a model into a slicer and it will give you a good idea of how much filament you need. Another factor to think about is how often you are going to be printing.

Say you are only making spinners every day or every two days, you should only need about 1kg of filament. Keep track of how fast you went through the first roll of filament. This will give you a better idea of how much you are using and the amount you will need to keep in stock for future purposes.

How Much Does It Cost to 3D Print a House?

As just mentioned, there are people who do extremely complicated projects with their printer. A great example: 3D printing a house. If someone were to put in the time and effort to print a house, you would at least hope that it saved them a lot of money compared to a real house. Well, let’s see if people saved money, and if they did, how much.

Average Amount Saved 3D Printing a House

On average, people can save anywhere from 30 to 55% by 3D printing their own home vs buying/renting a home. It usually costs less than $10,000 to make a small house, but it can even cost you less than $4,000 to make a home.

Believe it or not, there are 3D printed homes for sale! If you live in Los Angeles, you can find some 3D printed homes on the market. It’s not just in the U.S. either. Some other countries that have these homes for sale are China, Russia, and France.

It’s possible for most homes in the future to be made with 3D printing. The main issue that’s holding this back is the time it takes to print the parts needed. However, it’s much cheaper than the current method for building homes. This is what makes the future for 3D printed homes so bright. If 3D printing technology can be advanced to a place where printing the parts is done at a faster rate, it is very possible for it to be common to own a 3D printed house.

How Much Does It Cost to 3D Print a Figure?

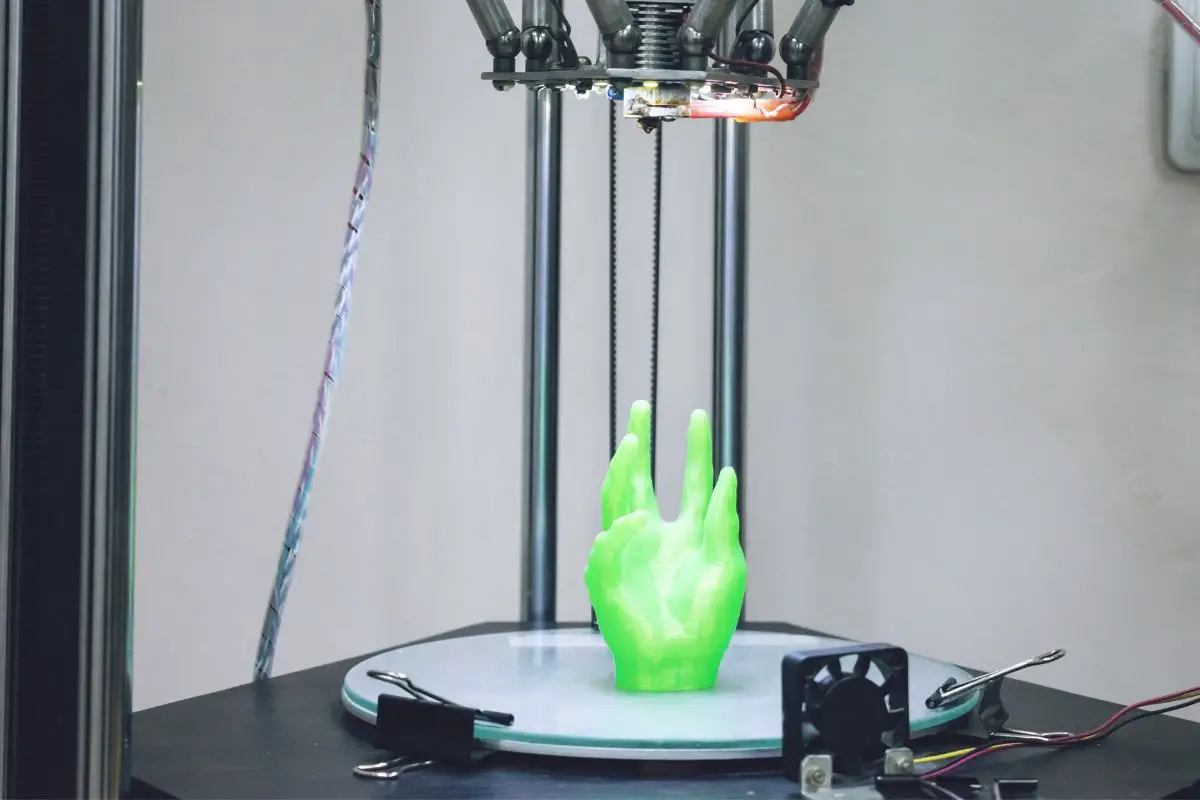

The saying goes “not one size fits all”. That saying applies to this question perfectly. Some of you may have really advanced 3D printers while others only have some basic models. The reason this is important is that the cost of the materials will be dependent on the type of materials you are using.

Say you are using high-quality materials for your printer, it’s going to cost you more for those high-quality materials than it would with a basic model. More advanced printers use more advanced materials. Basic printers use basic materials. To make this question easier to answer, I’ll be giving you the average cost. Keep in mind, that this cost may not apply to you.

- Thermoplastic- $3.50 – $7.50 per cubic inch

- Photopolymers- $0.32 – $0.36 per gram

- Polymers- $0.10 per gram

- Metals- $0.60 per gram

It should be noted that while polymer and metals are similar due to the fact that they are both in a powdered form as well as melted together, metals are a more expensive material so it will cost more per gram.

Thermoplastic is by far the most expensive. The main reason for the high cost is due to the fact that thermoplastics have much more thermal resistance compared to other polymers. Hence the name “thermoplastic”.

This should give you a general idea of how much it costs to print a certain figure and which materials will cost the least amount.

How to Calculate the Cost of 3D Printed Parts

I won’t go into too much detail in this section as the cost of certain parts has been shown above. I will, however, provide some more information on certain factors that can influence the price of the parts.

- Hourly Cost- Knowing how much you are printing per hour and how much it’s costing is important in order to save money

- Electricity Cost- Each printer is different so some may require more power to run than others. You can find out how much this is costing you by looking at how much electricity your printer consumes and knowing the average cost or energy for where you live

- Operator Cost- This part is generally the most expensive. You have to set the machine, slicing, post processing, etc.

It’s best to find out how much you are spending per hour. This will give you a better idea of how much you are spending. More importantly, create a reasonable time table for your project.

Say you find out that it’s costing you around $100 per hour (this is including the cost of materials, electricity cost, etc.) to print. If you can make a reasonable time table and believe that you can complete your project in 10 hours, then you will know that the project will cost $1000. This is just an example so don’t take the numbers too seriously.

What’s important is having a good estimate of the time it will take to complete the project. Humans tend to greatly underestimate how long it actually takes to complete something. Try not to underestimate.

How Big of a 3D Printer Do I Need?

When looking for a 3D printer, try to get one that has a build area of at least 5 x 5 x 5 inches (13 x 13 x 13 cm) and with dual extrusion. This is not too big but big enough for most printed parts. Only look for bigger industrial sized 3D printers if you are trying to print furniture or a house.

Very Important!

Some people think that since they are only planning on making small projects, they should get a smaller printer. While there is nothing wrong with this reasoning, I would still recommend getting a printer with a build area of at least 5 x 5 x 5 inches. Why?

To save money.

We all have a change of heart from time to time. You may originally plan to stick with small projects, but in the future, you may want to move on to those bigger projects. If your printer is too small, you are now forced to buy another printer. By buying a printer that’s big enough to cover most projects you won’t have to worry about buying a second printer.

How Long Does It Take to 3D Print Something?

Figuring how long it takes to 3D print something can be a frustrating thing to predict. Sometimes it will be done within 30 minutes, but in other instances it will take a whole week.

What determines how long it will take is the printing technology that’s being used as well as the size of the part. For example, a shorter object will print faster than a taller object even if both objects have the same volume.

What also determines the time is the number of parts. If you have one big square you are trying to print, it will be done quicker than a square broken up into multiple different pieces. This is because one big square is simpler for the printer to create. If the parts are broken up, the printer will have to account for that to ensure the pieces are made separately.

Then there’s infill. This is something you can do to speed up the process. Sold objects can be what is called “honeycombed”. This doesn’t fill up solid objects, which in turn, speeds up the process.

Speed Matters

Different printers have different printing speeds. However, just because a printer has a faster print time, that doesn’t mean it will have the same quality. Speaking of quality, you can choose the quality of the print by adjusting the height.

The lower the quality, the faster the print. Again, since it’s faster, the print won’t look as nice compared to a higher quality setting. Thinner layers are the ones that take longer to produce as they are higher in quality and smoother.

In general, most 3D printers will take around 5 or more hours to print an object that is the maximum size of their print bed.