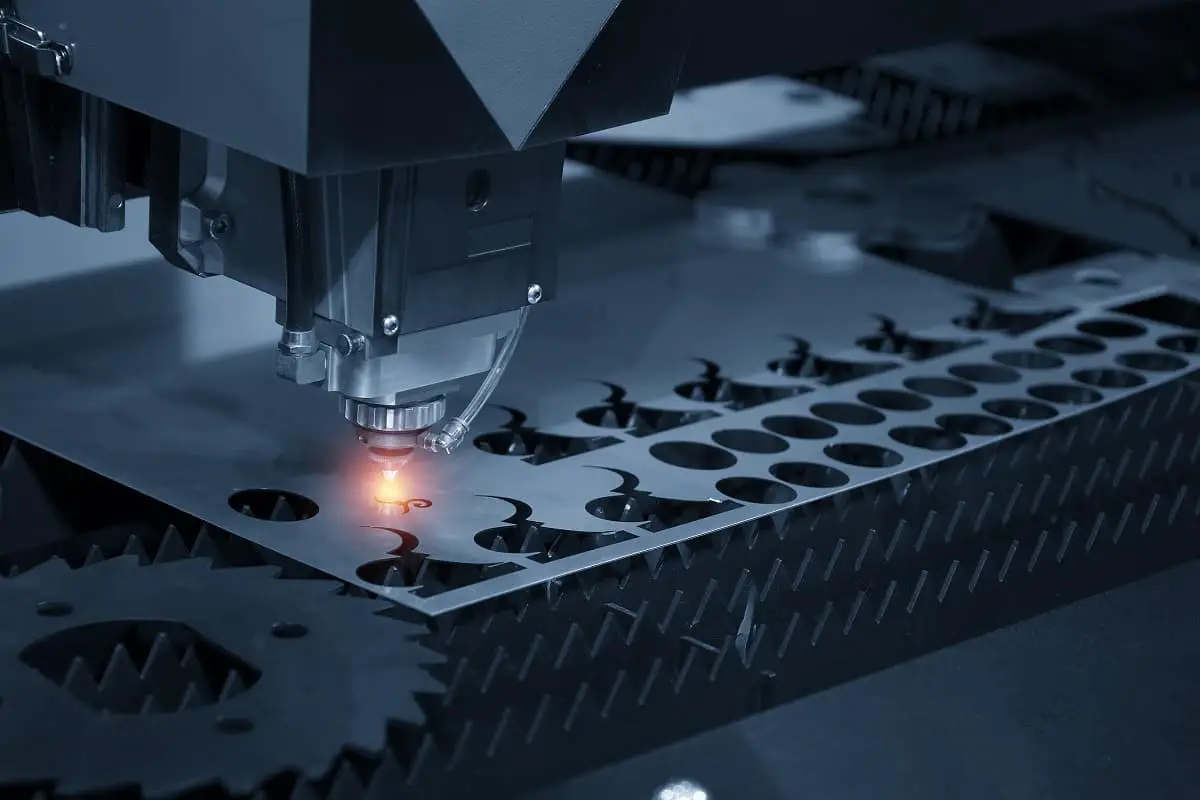

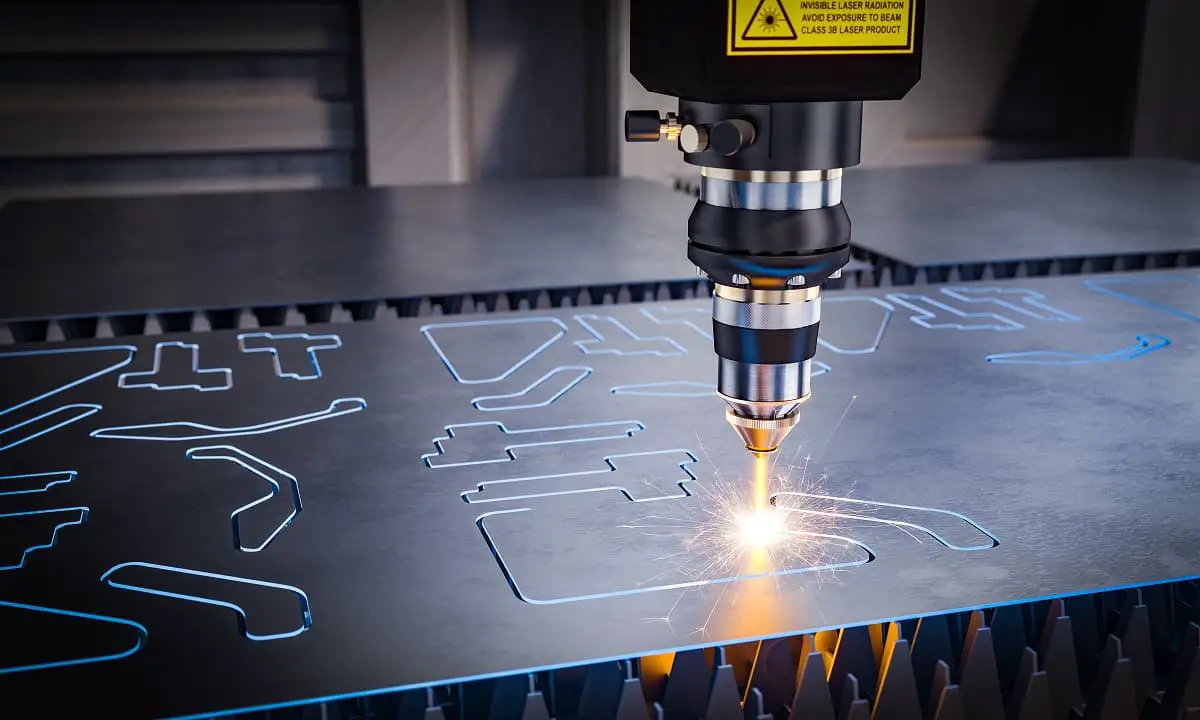

Laser engraving metal can be a bit intimidating to the novice user, but is much easier than some would think. Also you want be able to cut through metal like you can with a CNC plasma cutter, you will still be able to mark the metal enough to make it stand out. It is important to mention that not all metals or laser engravers will work for this procedure. So, let’s walk you through on how to laser mark metal.

How to laser engrave metal

There are a few things that you need to do before laser engraving anything made from metal to ensure that you receive the best results possible. For starters, you will need to decide if you need to engrave the object radially.

While many metal engraving projects have flat surfaces that allow the laser beam to move evenly across the surface without creating any distortion, you will likely want to radially engrave any projects that have curved, spherical, or cylindrical shapes.

This requires a unique component that can facilitate 360° engraving for situations where it is necessary. However, it is not worth purchasing this component if you do not see yourself engraving rounded objects frequently.

Laser Engrave Metal using CerMark

The easiest way to laser engrave metal is by using a special coating called CerMark. It allows you to engrave almost any type of metal without needing a high-powered laser machine.

It is important to use the right type of coating for the materials you are using. Follow the instructions and let the fun begin. The CerMark coating allows you to even laser stainless steel like tumblers and mugs.

Preparing metal to be laser engraved

The next step is to program your laser engraver to perform the engraving task after you have your project ready and have gathered the materials required. You can program anything from detailed stylistic designs to a simple numbering or text into the engraver’s program software.

Make sure that you are following the safety procedures that are associated with your engraver, and begin the actual engraving. There are certain laser classifications that determine their safety protocols and alsos check with the manufacturer before operating.

Class One lasers are either high powered or low powered but are both enclosed within a safe container while they are in use. Class Two lasers are exposed and usually form part of a production line. These laser engravers require a much higher level of caution when in use, as they can seriously injure anyone who mishandles them.

What are metal laser engravers?

Laser engravers are usually at the top of DIY craft enthusiasts’ must-have lists. These unique pieces of equipment are used to penetrate and cut through materials to engrave a design onto them and are operated autonomously using a computer, much the same as 3D printers.

Laser cutting technology is not necessarily an new technology. However, in recent years the laser cutters have expanded into consumers hands rather than just industrial purposes. Their prices have also decreased significantly enough that they are readily affordable for most DIY crafters.

The technique of laser engraving does not require any auxiliary or peripheral tools or apparatus that make contact with the engraving surface. Nor does it include using any sort of inks or pigments. This gives it a unique advantage over other engraving methods and techniques, as it does not wear out the surface. It also does not require any replacement parts that would otherwise be needed.

Laser Components

Laser engravers consist of three central components: a controller, a laser, and a surface, which technically does not form part of the engraver itself. The laser itself is a kind of drawing tool, as the beam that is produced from it lets the controller trace patterns onto the engraving surface.

Having a controller is what determines the speed, direction, intensity, and spread of the laser beam that is being aimed at the surface. The surface is also chosen to match the type of material that the laser is able to affect.

The point at which the laser beam comes into contact with the project surface is usually on the focal plane of the optical system of the laser and is also called its focal point. This particular point is generally minuscule, sometimes less than a millimeter in diameter. Also, only the area within this point is affected when the laser beam touches the surfaces.

What Else Can You Use Your Laser Engraver For?

When you have a laser engraver in your “tool belt” it opens you up to a lot of creative and artistic possibilites. Also, another useful thing about laser engravers is that they are also capable of what is known as laser marking. This is where the laser heats the surface of your desired material and turns it dark gray or black, essentially staining it, while the actual surface otherwise is not altered.

A laser engraving machine can also be used for laser etching. This is a method of engraving whereby the material’s surface is melted so that the mark is raised above the rest of the surface.

Finally, laser engravers can also be used for annealing, in which a large amount of heat is applied while the severity of the mark that is produced is lessened. The result is a black marking that has a smooth finish and is commonly used in the medical industry.

Conclusion

Laser engraving metal is one of the most satisfying forms of diy. The items that you engrave can often be turned into trinkets, jewelry, custom signs, and other decorations. Follow the steps we mentioned above, and you’ll be laser engraving metal as the pros do!