Laser engraving and laser marking are two common techniques used in the world of customization and personalization.

Both of these methods involve using a laser to etch designs onto a variety of materials, from metal to glass and plastic.

But, despite their similarities, there are some significant differences between the two techniques.

In this article, we will explore the differences between laser engraving and laser marking, so that you can make an informed choice about which method is best for your specific needs.

Definition of laser engraving

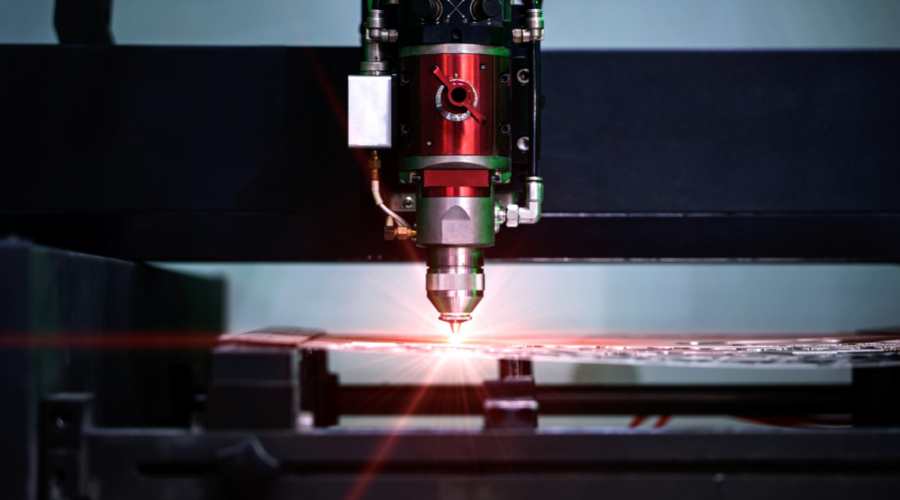

Laser engraving is a process that uses a laser beam to remove material from a surface, creating a permanent design. This technique is used to create designs on a wide range of materials, including metal, glass, stone, leather, acrylic and other types of plastic.

The laser beam is directed at the surface, burning or vaporizing material to create a design.

The precision, accuracy, and versatility of materials of laser engraving makes it ideal for creating intricate designs and logos, as well as inscriptions, such as serial numbers and product codes. In fact, there are tons of different laser engraving ideas out there.

For example, laser engraving is often used in industries such as jewelry, where a fine level of detail is required, or in the production of machine parts where a durable and long-lasting marking is essential.

The depth of the engraving can be controlled, making it possible to create shallow or deep designs.

The end result of laser engraving is a permanent mark that won’t wear off or fade over time.

Definition of laser marking

Laser marking, on the other hand, is a process that uses a laser beam to change the surface of a material, rather than removing material. The laser beam creates a permanent mark on the surface of the material, usually by oxidizing or discoloring the material.

Laser marking is often used to mark items such as electronic components, medical instruments, and consumer goods.

The main advantage of laser marking over laser engraving is that it is a non-contact process, meaning that the material being marked does not need to be physically touched. This makes laser marking a more efficient process for mass production, as it does not cause any wear and tear to the material being marked.

Laser marking can also be used to create barcodes, QR codes, and other types of identification marks.

The marks created by laser marking are usually less deep than those created by laser engraving, but they are still permanent and won’t wear off over time.

The main types of laser marking include:

Annealing Laser Marking

Annealing laser marking uses high heat to change the color of metal materials, such as stainless steel, creating a permanent and high-contrast mark.

Carbon Migration Laser Marking

Carbon migration laser marking uses high heat to move carbon within metal materials to the surface, creating a contrasting mark with a high level of detail.

Foaming Laser Marking

Foaming laser marking uses high heat to create small gas pockets within plastic materials, resulting in a raised and permanent mark on the surface.

Coloration Laser Marking

Coloration laser marking uses a high-power laser to change the color of certain materials, such as anodized aluminum, creating a permanent and highly visible mark.

Laser source

The source of the laser beam is also a key difference between laser engraving and laser marking. Laser engraving typically uses a CO2 laser, which produces a beam that is well-suited for removing material from surfaces. On the other hand, laser marking often uses a fiber laser, which produces a beam that is well suited for changing the surface of materials (especially metals such as stainless steel and titanium) without removing material.

The choice of laser source will depend on the specific needs of the project, with CO2 lasers being a better choice for engraving and fiber lasers being a better choice for marking. It’s important to choose the right laser source to ensure that the results are of the highest quality and that the process is as efficient as possible.

Cost

The cost of laser engraving and laser marking can vary widely, depending on the specific equipment and materials used, as well as the complexity of the design. Laser engraving typically requires more specialized equipment and can be more expensive than laser marking.

However, the cost of laser marking can also add up quickly, especially when marking large quantities of items.

It’s important to consider the total cost of the project, including the cost of the equipment, materials, and labor, when choosing between laser engraving and laser marking.

In some cases, it may be more cost-effective to use laser marking, while in others, laser engraving may be the better choice. It’s important to do a cost analysis to determine which option is best for your specific needs and budget.

Quality of the mark

The quality of the mark created by laser engraving and laser marking can also vary.

Laser engraving creates a deeper, more permanent mark that is well-suited for intricate designs and fine details. The mark created by laser marking is typically shallower, but still permanent, and is best for creating simple markings, such as product codes and identification marks.

The quality of the mark will also depend on the laser source used, as well as the specific equipment and materials used. It’s important to consider the specific requirements of your project when choosing between laser engraving and laser marking to ensure that the end result meets your standards.

Material compatibility

Finally, it’s important to consider the compatibility of the material you’re marking with laser engraving or laser marking.

Some materials, such as glass and metal, are well-suited for both laser engraving and laser marking, while others, such as some plastics, may only be suitable for one of these methods.

It’s important to choose the right method for the specific material you’re working with to ensure that the end result is of the highest quality.

If you’re unsure about the compatibility of your material with laser engraving or laser marking, it’s always best to consult with a professional or do some research to determine the best approach.