The 3D printing industry is constantly growing with new advancements. New machines are being designed to print different types of materials such as composites, metals, plastics, and many more. So, what material does a 3D Printer print with and which one is strongest? When it is about 3D printing, there are many materials to choose from.

All these materials have their own set of strengths, weaknesses, and features like indoor and outdoor use. And, there are some things you need to consider to avoid mistakes in this business. These may include, cost, texture, material type, etc. Continue reading the post to know more about the kind of material used in 3D printing.

What material does a 3D Printer print with?

Here is a list of some materials used by a 3D printer.

Acrylonitrile Butadiene Styrene (ABS)

It is a thermoplastic used regularly as a 3D printer filament. It is a material commonly used in household or personal 3D printing. ABS is a common material to be used in almost every 3D printer. This material is less expensive, accessible, and available in a variety of colors.

Nylon

Also known as polyamide, nylon is a synthetic thermoplastic polyamide and a common plastic material. Because of its corrosion resistance, low friction, durability, and flexibility, nylon is a popular 3D printing filament. Nylon is inexpensive and counted among the toughest plastic material.

Polylactic Acid (PLA)

This kind of material is extracted from renewable resources such as cornstarch or sugarcane. PLA is commonly known as green plastic. This material is mostly used in schools, both primary and secondary since it is easy to print with and safe to use. Polylactic Acid is used in FDM desktop printing.

Resin

It is one of the commonly used materials for 3D printing. Resin is used mainly in technologies such as CLIP, Multijet, DLP, and SLA. There are different kinds of resins such as flexible resins, tough resins, castable resins, etc. And, each of them can be used in a 3D printer.

Polyethylene Terephthalate (PET)

This material is mainly used for making plastic water bottles. PET is a recyclable filament. Objects printed with this material can be recycled as well.

Wood fiber (PLA + cellulose)

This kind of material is robust in nature and has a higher strength made from PLA and wood fiber. It has the same look, feels, and smell of natural wood. Wood filament is a great alternative to woodworking.

Polyvinyl Alcohol (PVA)

When it is about a support material to be used for complex objects, PVA filament comes to play. When the printing is done, the PVA has to be cleaned with water to create the open spaces on the object.

Suggested Article: 3D Printer Resin vs Filament: Which is Better?

Which 3D printing material is strongest?

Nylon, PLA, and ABS are the commonly used 3D printing materials. They are also the affordable materials available today for this purpose. ABS and PLA are thermoplastics. Although PLA is stiffer than ABS, it has poorer heat resistance properties. That makes PLA a hobbyist material.

ABS, on the other hand, is less rigid and weaker. But it is lighter, tougher, and makes a good plastic intended for prototyping applications. While nylon has properties that feature a great chemical toughness and resistance as compared to ABS and PLA. Nylon has a reduced strength as well.

ABS, PLA, and nylon are the best materials for beginner thermoplastics because of their ease of printing and low price count. But, if you are thinking to start 3D printing for industrial uses, nylon provides superior properties needed to resist manufacturing environments.

Suggested Article: Best 3D Printer under $1000

How expensive is 3D printing material?

These days, the selection of 3D printing materials is larger than ever. Polymers and metal are the two basic categories, and both of them are further divided into subcategories. PET, ABS, PLA, wood-like, carbon fiber, etc. materials for 3D printers can cost between $20 and $70 per kg.

The standard polyamide powder for SLS makers can cost from $45 to $75 a single kg. The price of standard 3D printer material for SLA resins is about $50 per liter. Cheap resins are available below the said amount. Yet, some resins intended to have a perfect surface finish can cost up to $500 a liter. Knowing how much material costs will help you understand how much filament you will need.

Metal powders are used when 3D printing on metal. But, these powders are very expensive. When you are about to buy metal powders, expect to pay about $350 to $550 per kg. Remember that these prices mentioned may not be applicable for all kinds of materials but they are quite nearer to the prices on sale these days.

Best 3D printing material for Outdoor use

The most commonly used materials for 3D printing are ABS, PETG, PLA, and ASA, which is used to a lesser extent. The best 3D printing materials intended for outdoor use are ASA and PETG. These materials are durable and hold over time. They are perfect to work on rough conditions without deforming appearance and shape.

Both these materials are insensitive to UV rays and changing temperatures. Because these materials are highly resistant to deformation, they remain steady despite the sun and wind. Even the sun’s harmful UV rays don’t cause significant changes to the color or shape of the 3D printed objects made from ASA and PETG.

What to do with 3D printer waste?

The plastic material wastes are melted and recycled with certain amounts of efficiency and matter loss. Yet, the most common 3D printer materials PLA and ABS can’t be recycled by most of the municipal recycling programs. Even PETG is excluded from most programs.

But, many of the thermoplastics used in 3D printing could be melted down and re-squeeze with a little loss of material. Making use of such a machine at your home could be a bit more advanced than using a 3D printer. But, it is within the reach of a hobbyist.

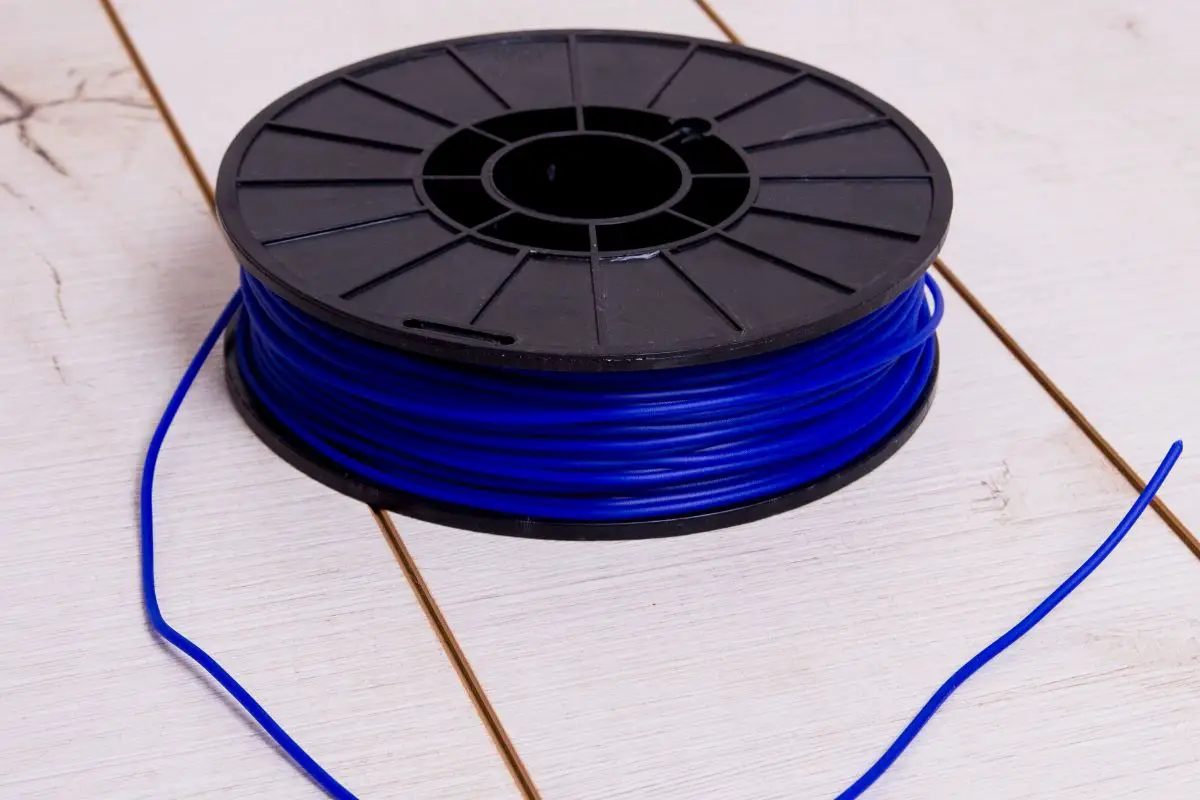

A filament extruder is a great way to recycle your 3D printer waste. All you need to do is shred the waste plastic into pieces, melt it down and extrude with a filament extruder.

Suggested Article: How to clean your 3D printer bed: Detailed Guide

Conclusion:

With the right kind of materials used and proper knowledge equipped, 3D printing can be done effectively. Knowing what materials to use with a 3D printer is a must. With that knowledge you will be able to make an informed decision on the best and strongest material for outdoor use.

As the industry grows, different kinds of materials will be utilized for making objects. Also, those kinds of materials will be compatible with almost every 3D printer.