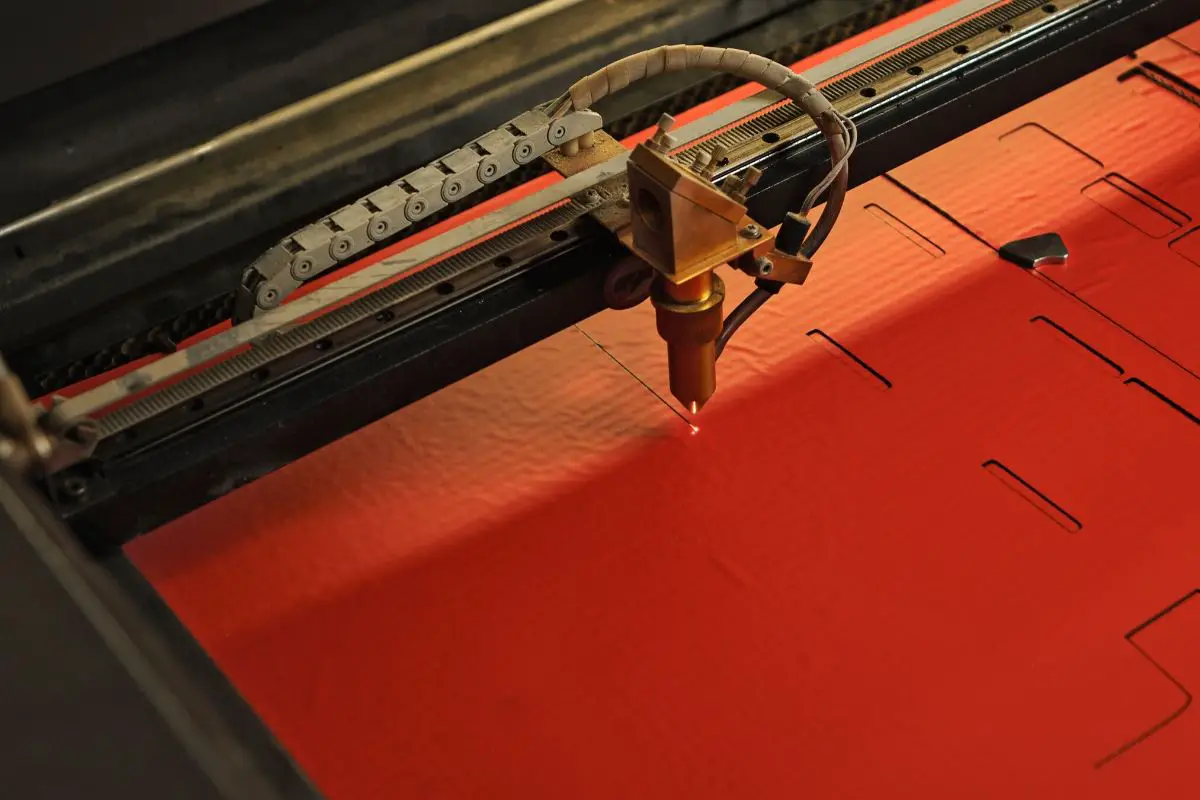

Laser cutters are a popular technology to cut, engrave, or etch designs into a material by using laser beams to vaporize the materials. While commonly used on wood, there are plenty of other materials you can use with laser cutters and for varying applications. It is also important to know the materials to avoid. Mostly they are ones that don’t vaporize but instead melt or ones that will lead to dangerous fumes.

This laser cutting materials guide will cover 10 different material types suitable for laser cutters, what you can make with them, and information on the best ways to use them. This guide will also provide a list of materials to avoid and why.

-

Wood

Almost all laser cutters are capable of engraving, etching, or cutting wood. It is one of the most common materials for making various products. Just make sure the machine you have has a large enough workspace for the type of wood you want to utilize. Examples of wood-based materials typically used include:

- Pine

- Cherry wood

- Baltic birch plywood

- Birch veneer

- Clipboard material

- Bamboo

- Medium-density fiberboard (MDF)

Out of the list above, birch is one of the most versatile for various projects. If you want thicker wood, then choose birch veneer. However, if you want something budget-friendly that is easy to glue and paint, MDF is a popular choice for hobbyists. It’s best to use MDF materials that are around 0.24 inches thick.

Wood Applications

- Signs

- Cabinets and other furniture

- Wooden puzzles

- Clocks

- Coasters

- Jewelry boxes

- Beer cases

- Bookmarks

- Model airplanes or boats

- Prototypes

- Combs

- Jewelry, including earrings, pendants, and necklaces

-

Plastic

Only some plastics are suitable for laser cutters. The most commonly used one is acrylics, since it is also the most affordable. Black acrylic is popular among hobbyists since engraving on it creates a beautiful, frosty white design. Matte black acrylic around 0.12 inches thick can also be cut or engraved to create a silky satin finish that is sophisticated.

Other plastics such as Delrin, polyethylene, mylar, and polyurethane can be cut by laser cutters with as low as 40 wattages of power. However, most of these plastics are used for industrial products.

If you want to cut clear polycarbonate or carbon fiber, you will need at least a 1064 nanometer fiber laser cutter. Take note, never cut coated carbon fiber as later explained in this article.

Plastic Applications

- Prototyping

- Signage

- Engraved tableware

- Conference badges

- Point of sale displays

- Book covers

- Bird feeders

- Cake toppers

- Electronic covers

- Business cards

-

Metal

Most laser cutters can engrave or cut soft or thin metals. Laser cutters with power between 40 to 150 wattages can cut steel, plain carbon steel, and anodized aluminum. However, you will need a 20 to 500 wattage fiber laser cutter for:

- Titanium

- Silver

- Bare aluminum

- Copper cladding

Metal Applications

- Signage

- Fences

- Jewelry, including rings, belt buckles, necklaces, and tie clips

- Clocks

- Wall art

- Robotic arms

- Metal parts to various products

-

Rubber

Co2 laser cutters can be used on low odor rubber, silicone, and vulcanized rubber. It will produce a smooth cut and sharp edges on Neoprene rubber. If you find a slight discoloration on the edges, you can typically clean it up after processing. Silicone rubber is only best when you engrave it, since cutting can burn the edges and leave a less appealing finish.

Rubber Applications

- Stamps with text, logos, or images

- Coasters

- Keychains

- Waterproof covers

-

Textiles

Laser cutters can easily create designs onto various fabrics and organic materials, a process also known as digital embroidery. You can use a laser cutter to engrave or mark felt or fleece as well as to cut or engrave natural or artificial textiles, including:

- Polyester

- Nylon

- Silk

- Wool

- Cotton

- Denim

Leather is harder to cut but still possible, especially if you cut thinner pieces around 0.125 inches thick. Laser cutters can engrave unique patterns, shapes, texts, art, and logos onto leather effectively. Whether you are cutting or engraving, make sure to never use artificial leather or leather that contains chromium (VI), as later explained why in this guide.

Textile Applications

- Decorate pillows or fabrics to make clothes

- Felt or leather coasters

- Leather belts

- Leather bracelets

- Bookmarks

- Electronic covers

- Bags and purses

-

Glass

Laser cutters are great for etching designs onto glass materials for custom-made products. It typically works by etching away the reflective surface with no impact on the glass. Green glass is a popular option because it creates a sandblasted effect. You can also use it on:

- Other colored glass

- Clear glass

- Window glass

- Mirror glass

- Tempered glass or crystal

- Sapphire

- Sheet glass

- Glass bottles

Most laser cutters work on flat glass materials only, so double-check if yours is compatible with round or cylindrical items. It also isn’t recommended to cut glass with laser cutters. However, you can accomplish this with high-powered machines that have cooling systems.

Glass Applications

- Add text, designs, or images on wine or beer glasses

- Personalize goblets, bowls, cups, and plates

- Stained glass products

- 3D crystal gifts

- Etch photos onto glass

- Glass jewelry

- Awards and plaques

-

Stone

Laser cutters can engrave or lightly etch various stone materials. Marble is the most popular material you can easily engrave. However, you can also etch:

- Granite

- Ceramic tile

- Brick

- Agate

With a high-powered machine, you can cut materials such as ceramic, which is commonly used as an insulator in many industries. Many products such as motors, loudspeakers, lamps, and electric cooktops have ceramic parts in them.

Stone Applications

- Sculptures

- Plaques

- Garden or home tiles

- Wall art

- Jewelry box

- Phone holder

- Parts for larger products containing ceramic

-

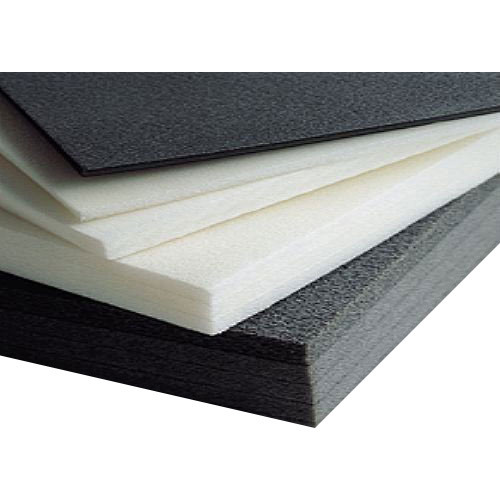

Foam

While not as commonly used, laser cutters can also work with foam as long as you monitor the machine. The best foams for marking, engraving, or cutting are:

- Polyester (PES)

- Polyethylene (PE)

- Polyurethane (PUR)

Depron foam is used a lot by hobbyists since it cuts nicely and creates a smooth edge. While you can cut gator foam and solid styrene, it can get easily burned or smoke a lot.

Foam Applications

- Cutting thick pieces for inserts

- Packaging material

- Seals

- Custom puzzles

- Architectural models

- Toys or building blocks

- Aircraft models

-

Cork

You can use laser cutters to cut cork. However, the quality of the final results will depend on the quality and thickness of the cork. It is best to avoid thicker cork and any engineered cork that contains a lot of glue in it, since these don’t cut as well.

Cork is not the best material for engraving since it is softer and easily cuts all the way through, but with care, you could manage etching designs or text onto customized pieces.

Cork Applications

- Personalized wine corks

- Engraved coasters

- Wall art

- Succulent pots

-

Cardboard or Paper

Cardboard or paper are popular options for laser cutting because it is inexpensive and can easily be cut or engraved. For detailed designs on paper, you will want to use a machine that has high precision and accuracy.

Laser cutters can cut corrugated cardboard, gray cardboard, or cellulose cardboard. However, if you plan to create model toys or buildings from cardboard, gray or cellulose is best.

Cardboard or Paper Applications

- Business cards

- Wall art

- Signage

- Advertising materials

- Model-building pieces

- Paper art

- Shadowboxes

- Wedding or party decor

Materials Not to Use

Besides knowing what options you can use with laser cutters, it’s also important to understand unsafe materials and why they should be avoided.

Polyvinyl Chloride (PVC)

Mechanical cutting methods are better than laser cutters for PVC since it releases toxic chlorine fumes. These fumes can corrode the metal on your machine and ruin the motion control as well as is dangerous for you to inhale. PVC materials include:

- Vinyl

- Pleather

- Artificial leather

Thick Polycarbonate

While polycarbonate under 0.04 inches thick is okay to cut using a fiber laser cutter, any thicker can cause issues. You can experience patches of discoloration or even burning since the thickness absorbs the laser’s infrared radiation.

Fiberglass

While in general, glass is not the best thing to cut with laser cutters, fiberglass poses an additional danger since it is made of epoxy resin and glass. The epoxy resin causes emissions of toxic fumes.

Polystyrene Foam

While you can cut thin pieces of polystyrene foam, it is also one of the number one materials that lead to laser fires. This material can easily burn, catch fire, and melt.

Polypropylene Foam

Polypropylene will also melt and catch on fire. Any melted substances will continue to burn and turn into hard pebbles and drips, potentially damaging your machine and work table.

Acrylonitrile Butadiene Styrene (ABS)

Unless you want a messy work table and ruined machine, avoid using ABS. This material catches fire and melts to leave a gooey substance instead of vaporizing under the laser’s heat. For the same reason, it doesn’t engrave well.

High-Density Poly Ethylene (HDPE)

HDPE is made from petroleum and is very versatile but not optimal for laser cutters. Also known as milk bottle plastic, HDPE reacts similarly to ABS. It catches fire and melts into a gooey mess instead of holding up against the laser heat.

Coated Carbon Fiber

While you can cut carbon fiber mats, even though with some fraying, you want to avoid coated carbon fiber. The added coated material emits noxious fumes that are harmful to inhale and can have corrosive effects on your machine.

Conclusion

Laser cutters can be used with a wide range of materials, from popular ones like wood, metal, and plastic to textiles, glass, and paper. While you can safely use these materials with laser cutters for etching, engraving, or cutting, not all are created equally or suitable for all machine types. Make sure you research the materials your machine can handle before use. Also, always avoid materials that can catch fire, melt, or emit dangerous fumes.