Anyone interested in becoming a Maker has gone through the process of deciding on what machine they should get. There are a lot of possibilities depending on what you would like to accomplish.

So, that’s where the decision often comes down to a Laser Cutter vs CNC Router.

While they’re not exactly the same, each one offers a tremendous cutting ability depending on the machine you purchase.

Since each of them has its own benefits, it is not a simple answer as to which is better.

Let’s take a look at the main differences between a CNC router and Laser Cutter to see what’s right for your project and setup.

What is the difference between Laser Cutting and CNC?

While both laser cutters and CNC routers use CNC programming to operate their machine, most of the similarities end there.

Laser Cutters are completely dependent on the wattage and power of it’s the laser to cut the materials you are using.

A router has a little more flexibility due to the various CNC router bits you can use when cutting.

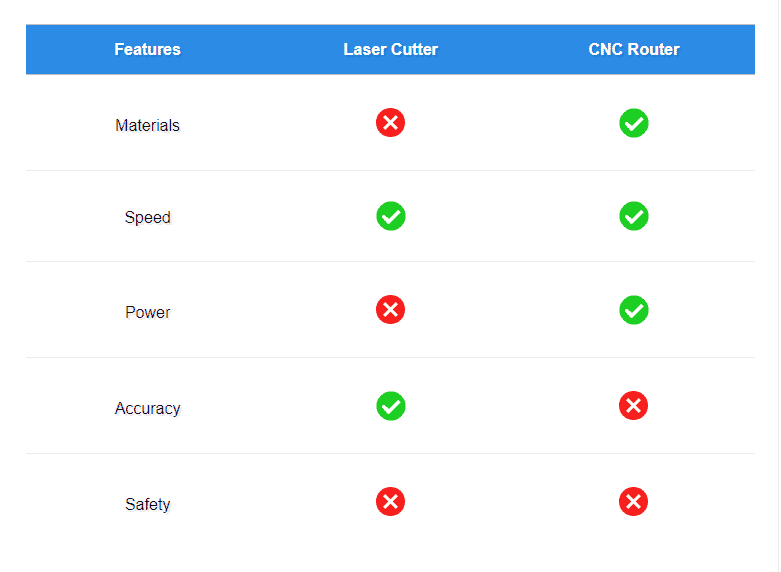

Materials

Lasers can cut through almost every material that a CNC router is capable of engraving.

But, some materials like PVC, ABS, polypropylene foam, etc. can’t be engraved through a laser machine.

On the other hand, a CNC router can take care of this task by following some precision. So overall, a CNC machine has the ability to cut more materials than a laser cutter but may require a dust collector.

Speed

When it is about the speed of these two engraving machines, there isn’t much difference.

The speed at which these machines perform depends on many factors, like the material used, the design, and so on.

Laser machines can have better precision since it isn’t directly coming in contact with the material, unlike a CNC Router. However, CNC routers can be considered quicker because they are able to take bigger passes while cutting a material like wood.

Laser cutters like the Glowforge move at a rapid pace but require many more passes in their tool path compared to a CNC machine.

Because a CNC can use various tool diameters, it can sometimes do an engraving much quicker than a laser engraver.

Power

When it comes to power consumption, it seems that lasers use more power than CNC routers. Also, lasers cost more.

But, when you engrave with a laser, the level of intricacy and precision is much better than CNC routers.

You get an extensive amount of control while performing with lasers. As a result, you may be able to explore a broader range of engraving and design projects.

Accuracy

Engraving with routers is like drawing with a marker pen. Whereas, engraving with lasers feels more like drawing with a fine pen.

As you know, the width of the cut depends on the width of your engraving tool.

You may find the smallest router bits with a radius of about 1mm, while the radius you find in a laser beam can be around 0.1mm.

Because of this, you can engrave detailed cuts with precision.

Irrespective of the design, you are guaranteed a much higher amount of accuracy and precision when it comes to your most intricate designs.

Safety

Always wear safety glasses and have proper ventilation in your work area while operating either of these machines.

When using a CNC Router it is extremely important that you have a good dust collection system in place.

And while both machines are a fire hazard, laser cutters are even more so (depending on the material you use – read this post on laser cutter heat to learn more).

It is important to always use materials approved by the manufacturer and to never leave the machine unattended.

Whatever machine you end up using, be sure to keep the safety manual close at hand in emergencies.

And always clear away any flammable materials, chips, or shavings away from any electrical components in the area.

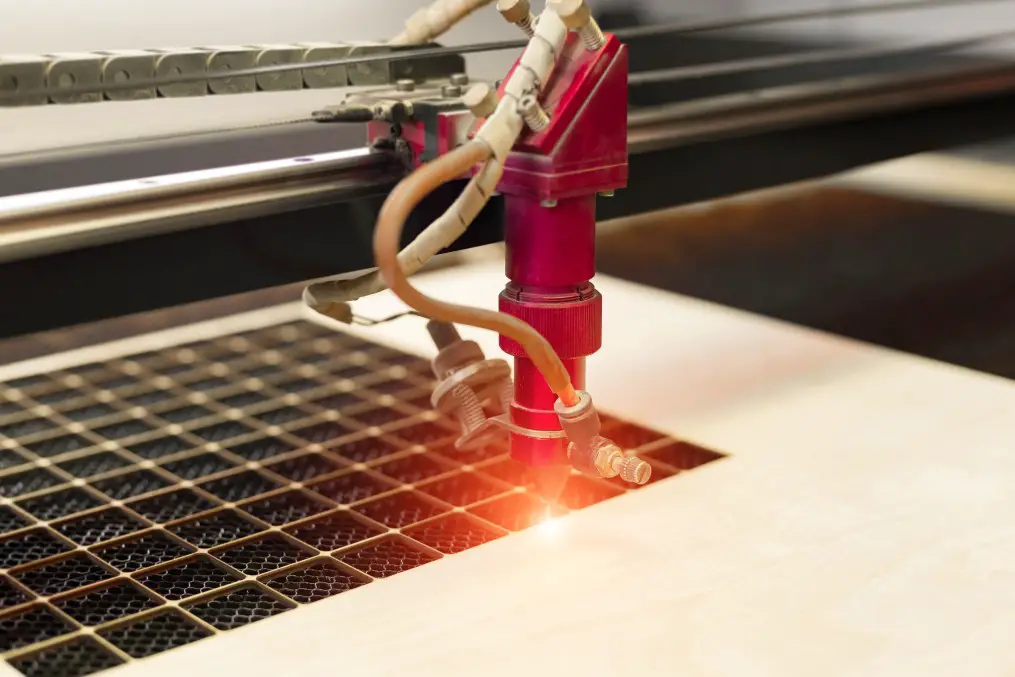

What are the advantages of Laser Cutting?

Many people love to have laser machines because of the list of upsides the device provides. The advantages of using the machine are precision, speed, cost-effectiveness, flexibility, great quality, and chances for automation.

The precision and accuracy of 0.1mm are also significant factors.

Laser engraving is also quicker than traditional methods, unlike CNC routers. Another advantage is that you can get Mini Laser engravers at a very low cost.

Making use of the right setup and material, you can have great designs.

With a laser engraver, only the beam comes in contact with the material. So, there is much less mechanical friction to worry about, and you’re not as concerned about managing tool life.

Talking about flexibility, you don’t have to exchange tools for a separate design.

Finding an affordable laser cutter is possible, which makes this a great option.

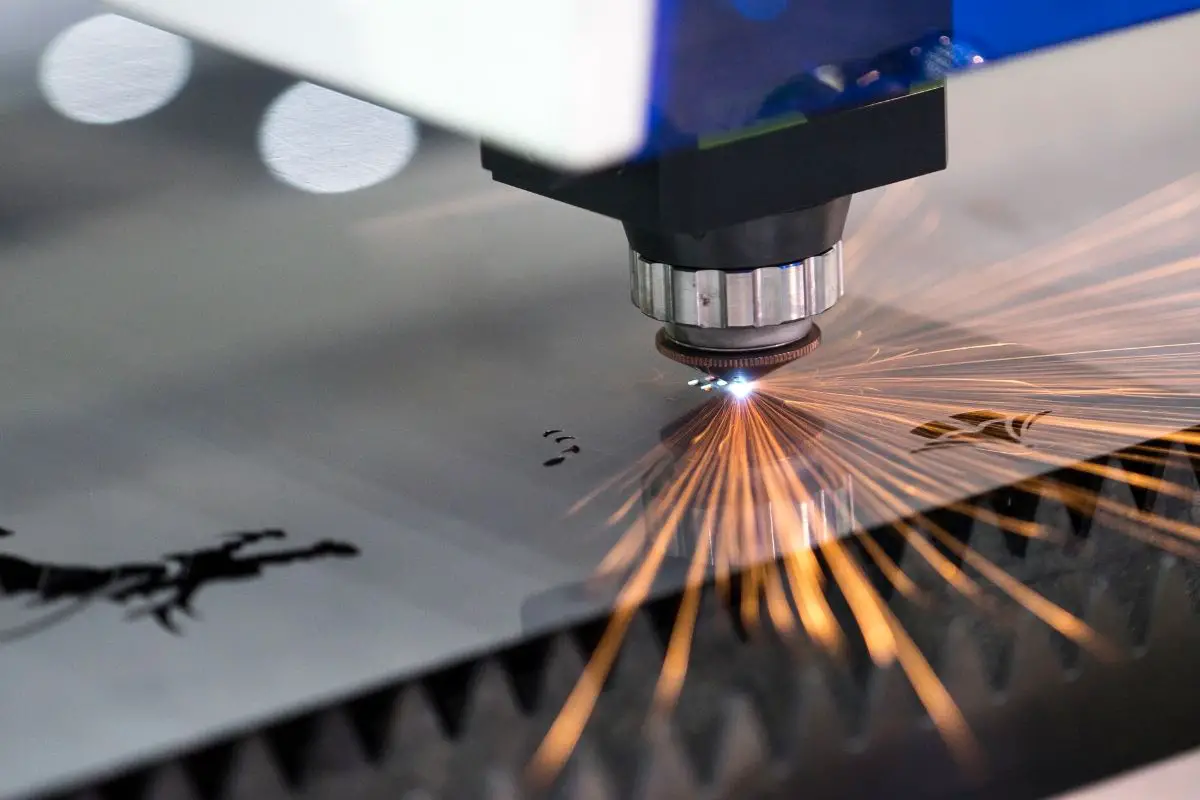

What are the disadvantages of Laser Cutting?

Used in the production of parts in many sectors, laser cutting does have its downsides.

These may include metal thickness limitations, hazardous fumes, upfront costs, and the need for expertise.

And compared to other thermal processes of engraving, it is not suitable to engrave thick plates.

The engraving method used results in melting some parts of materials, resulting in emitted fumes and gases that can be dangerous to health.

Another downside of a Laser Cutter is its respective size compared to a CNC Router.

Routers can be used in an unenclosed environment, unlike a power laser cutter, giving it a much larger cutting area in most cases.

What are the advantages of a CNC Router?

Unlike manual labor, a tabletop CNC router machine can work continuously over a stipulated time period without having frequent breaks. This way, it increases efficiency and productivity.

With the help of a software program, the design of a product needs to be programmed for a single time. The machine replicates the design for any number of quantities.

A large cutting area is also possible, like with a 4×8 CNC Router.

Also, although you definitely proper skill and training to operate a CNC router, many of the machines offer automation features. For example, the software may be reprogrammed to produce other parts quickly.

More intricate and complex operations are possible with this machine.

Did you know you can now get affordable CNC Routers for any budget? Click the link to learn more.

What are the disadvantages of a CNC Router?

CNC router machines are costly and require initial investments compared to machines that are operated manually.

Plus, you may need more training to operate a commercial-scale CNC router. While there are several desktop models available, the learning curve tends to be steeper when compared to a consumer-level laser cutter.

As mentioned, you also have to worry more about the various parts of a CNC router, including the end mills.

Essentially, there is more involved. But if you can master these skills, there is plenty of skilled labor available for CNC machinists, along with entrepreneurial opportunities in starting your own shop.

Final verdict: CNC router vs Laser cutter

There is no question that both these types of machinery are fantastic for your manufacturing unit.

It seems like lasers are favorites but it comes down to your specific needs. Laser engravers cost higher but have extra whistles and bells.

A CNC router may not engrave creative and precise designs like the laser, but gives you simpler designs for a cheap price.

Sometimes, this is what you may want from this kind of machine.