CNC is an abbreviation for “Computer Numeric Control,” a term that encompasses a large family of machines used by makers.

Although the term “CNC” technically describes any device that uses computer signals to control the movement of machinery, including 3D printers and laser cutters, in our case we’re focusing on CNC routers and mills.

Learning how to operate a CNC router will speed up your making process and greatly expand the range of parts and products you can produce in your workshop or makerspace.

To get you started on the path to CNC makerdom, we’ve included several links to our articles and resources in the following guide.

Getting Started with CNC Machines

CNC machines use subtractive manufacturing, or cutting technology, to turn raw stock, such as wood, foam, plastic, or metal, into a finished product.

To do this, a CNC controller feeds sequenced instructions to the machine tool, directing the movement of its cutting end to create the desired object.

CNC machines may be used for milling, turning or drilling. They can create complex 2D and 3D forms from a variety of materials, from custom car parts to heavy-duty tooling applications, or even designing your own toys, games, signs and even custom furniture!

Even modern desktop CNC routers feature production high-speed capabilities with excellent precision.

But, before jumping in, you’ll want to learn the basics about machine types and material compatibility.

For example, what’s the difference between a router and mill, and how can you tell which machine is right for the types of projects you plan to work on?

That’s where the following guides will come in handy:

CNC Router vs Mill

Learn more about the main differences and similarities between these two CNC machine types.

More articles to review:

Software and File Formats

CNC machines rely on digital design files, toolpaths and programming instructions to make precise 2D and 3D shapes and carve intricate designs.

The types of software used include 2D CAD, 3D/4D CAD and CAM programs.

In general, the CAD (computer-aided design) programs are for designing and creating a virtual model, while CAM (computer-aided manufacturing) software lets you preview the project and converts it into toolpaths (G-code) for the machine to understand and execute.

Understanding how to use design software, along with various file types and the basic programming language that controls your machine, is the key to unlocking the full potential of your CNC equipment.

Have a look at the following articles to learn more about CNC software, project files, hardware and programming tools:

Free CAM CAD Software for CNC Routers

Our top 5 fee software picks to design virtual models for your CNC routers.

More computer and software related articles for CNC machines:

- VCarve Pro vs Aspire : CNC Router Software Comparison

- A Guide to CNC Programming

- What is G-Code? Your Complete Guide

- Everything You Need to Know About GRBL Control

- Best Laptop for CNC Router: Complete Buying Guide

CNC Parts and Components

Once you get into the world of CNC, you’ll want to learn more about the anatomy of the equipment, including its key parts and components, so you can fix, modify or even make your own machine someday.

The focus of this site is on hobby level CNC routers. And, in this category, you can quickly learn about the makeup of your machine with an overview of the following parts:

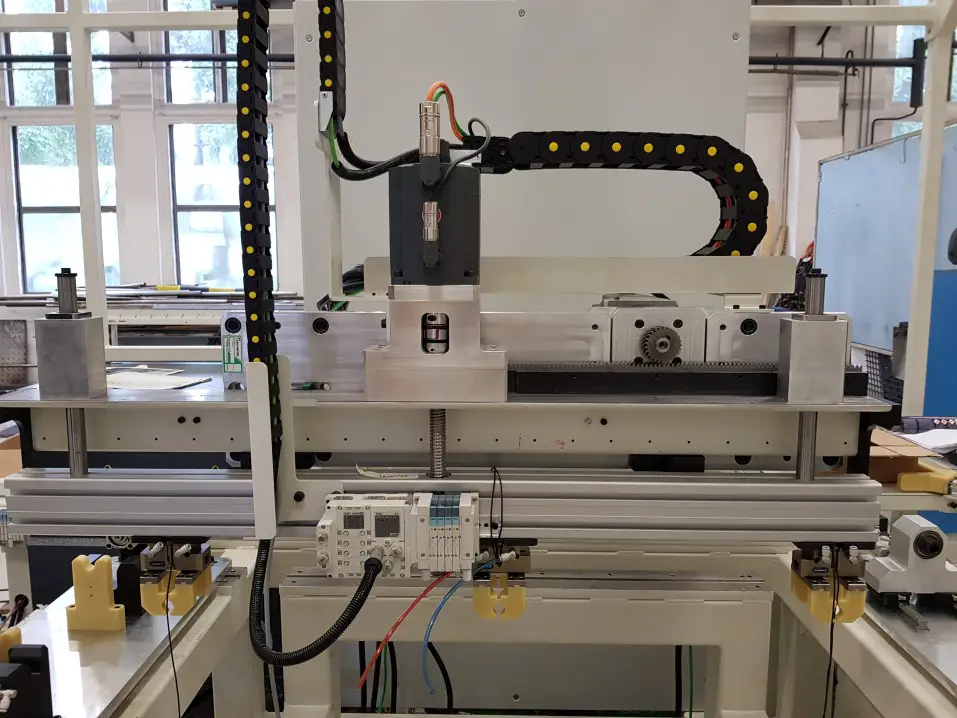

- Gantry – Spans the width of the X-axis (left-to-right) and holds the carriage, moving forward and backward along the Y-axis.

- Carriage – Moves along the X-axis gantry and holds the spindle and Z-axis (up and down) motor and rail.

- Spindle – Sometimes referred to as a router, although quieter and more precise, the spindle is attached to the carriage and rotates the cutting tool (end mill, cutter, bit, etc.)

- End Mills (aka bits) – These are the end cutting bits, attached to the spindle, that come in a wide range of lengths, cutting profiles, geometries and tip styles depending on the project, shape and material.

- Table – This is where your stock material will be secured for routing and may include different clamps, t-slots, frame materials and designs, and other fastening systems (including tapes and groove systems).

- Controller – Connects your computer, usually via a USB connection, to your CNC machine so it can load your G-code and perform cutting sequences.

Those are the basic components, but there is a lot of variation in parts when it comes to different brands, sizes, and material capabilities.

You can learn more about CNC parts and accessories with the following guides.

Basic Guide to CNC Parts

Learn more about the part and functionality of your basic CNC router setup.

More articles to review:

- Must have CNC router bits

- What is tool life? And how can you optimize it for your CNC machine?

- How long do CNC router bits last?

- Best router bits for aluminum

- Best router bits for plywood

- Best dust collection system for your CNC router

What Can You Make with a CNC Router?

Now for the fun part: what can you actually make, and perhaps even sell, with your new CNC skills?

Whether you have your own desktop CNC machine, or if you have access to one through a local makerspace or school, there are so many possibilities when it comes to creating your own products and designs.

As mentioned above, you can make advanced 2D designs like signs and botanical carvings, or fun 3D items for your own use, like guitars, toys, games, kitchen items, molds, furniture, and much more.

We’re constantly on the lookout for new ideas and project files to feature on the site, but take a look at the articles below for some great ideas and project files to get started.

What can you make with a CNC Router?

Learn about just some of the possibilities for making things with a CNC router.

More design ideas and project files:

- 21 X-Carve Projects to Make and Sell

- FREE CNC Router Projects, DXF Files, and Plans

- Can you really make money with a CNC router?

- How to Price CNC Router Work: A Simple Formula

What is the best CNC machine to buy?

The market for desktop ready CNC routers, and more affordable machine options for small business owners, has grown rapidly. There are now many new CNC machines available for hobby level makers.

For example, you can find large communities of enthusiastic makers supporting the use and development of certain machines, such as the Shapeoko 4, Stepcraft, and X-Carve models, along with new CNC brands, cheaper imported models, and even scaled down versions of industrial mills.

To help you navigate the range of options and different types and levels of CNC machinery now available, we’ve included a series of buying guides, reviews and product comparisons.

What are the best tabletop CNC routers?

Learn about some of the best desktop or tabletop options available today.

More CNC buying guides and reviews to check out:

- Best 2×4 CNC Router Kit

- Best 4×4 CNC Routers

- Best CNC Machine Under $500

- Best CNC Machine under $1000

- Best Desktop CNC Mills for a Small Shop

- Best CNC Lathe for Small Projects